- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Are More Drilling Contractors Switching to GMS’s 110704 Cylinder Assembly, Counter Balance?

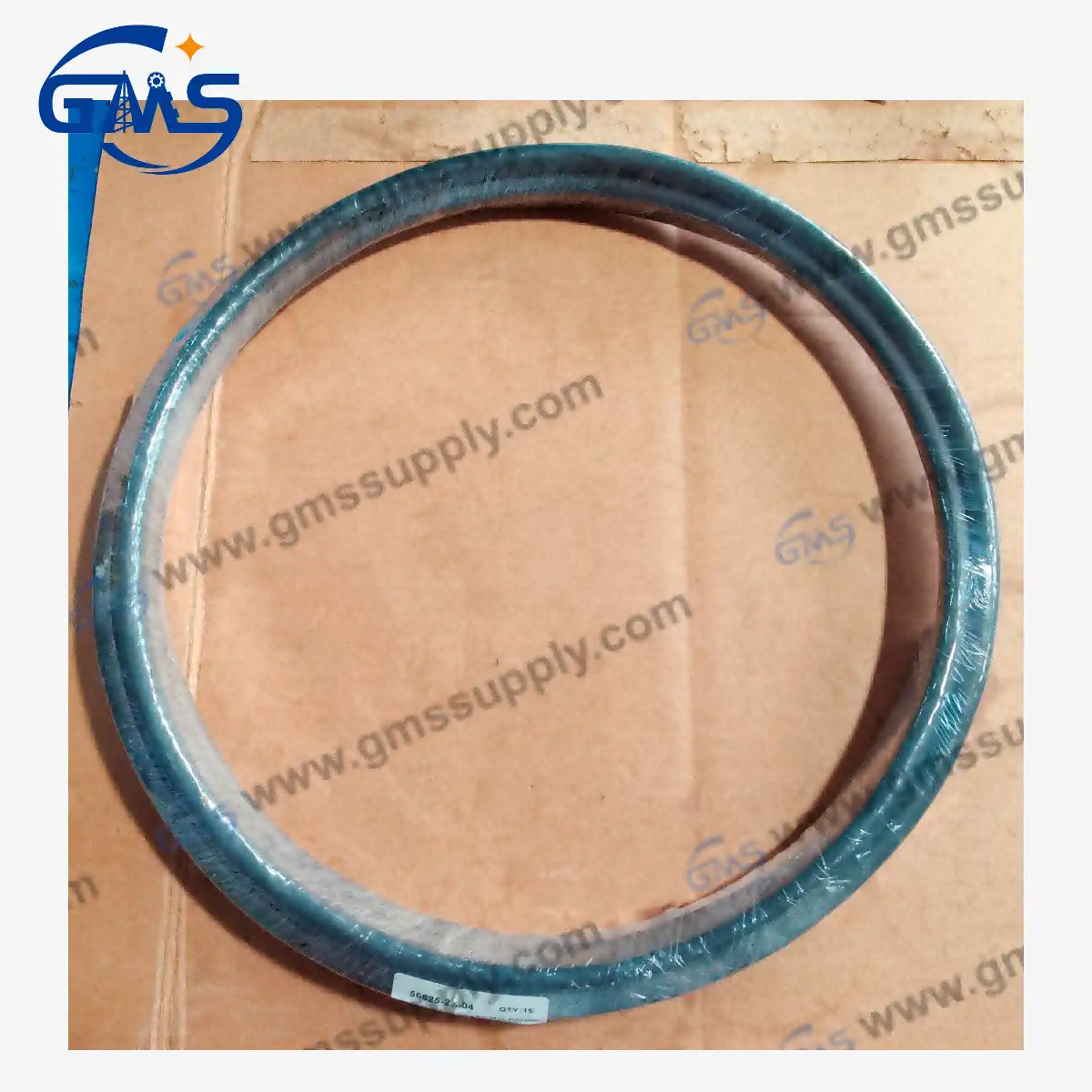

The drilling industry has witnessed a significant transformation in recent years, with contractors increasingly prioritizing cost-effective solutions without compromising operational reliability. The growing trend of switching to GMS's 110704 CYLINDER ASSEMBLY,COUNTER BALANCE represents a strategic shift that addresses both economic pressures and performance demands in modern drilling operations. This critical component, designed specifically for counterbalance systems in top drive applications, has become the preferred choice for contractors seeking to optimize their equipment performance while managing operational costs. The surge in adoption stems from the component's proven track record in maintaining load balance within counterbalance systems, particularly in TDS-11 and TDS-9SA models. As drilling contractors face mounting pressure to reduce operational expenses while maintaining safety standards, the 110704 CYLINDER ASSEMBLY, COUNTER BALANCE offers an ideal solution that delivers original equipment performance at a fraction of the cost. This shift represents more than just a purchasing decision; it reflects a fundamental change in how the industry approaches equipment procurement and maintenance strategies.

Superior Performance and Reliability at Reduced Costs

The primary driver behind contractors' migration to GMS's 110704 CYLINDER ASSEMBLY, COUNTER BALANCE lies in its exceptional ability to deliver original equipment performance while significantly reducing operational costs. This counterbalance cylinder 110704 is engineered with precision manufacturing techniques that ensure consistent performance across diverse drilling environments, from offshore platforms to onshore operations. The component's design incorporates advanced materials and manufacturing processes that match or exceed original equipment specifications, providing contractors with confidence in their equipment's reliability. The cost advantage becomes particularly evident when considering the total cost of ownership, where the initial savings on the 110704 CYLINDER ASSEMBLY, COUNTER BALANCE translate into substantial budget allocations for other critical operational needs. Furthermore, the component's robust construction ensures extended service life, reducing the frequency of replacements and associated downtime costs. Contractors have reported significant improvements in their bottom line after switching to GMS's solution, with many citing cost savings of up to 40% compared to original equipment parts. This financial benefit allows drilling operations to maintain competitive pricing while preserving profit margins, making it an attractive proposition for both large-scale operations and smaller contractors working within tight budget constraints.

Enhanced Operational Efficiency and Compatibility

The 110704 CYLINDER ASSEMBLY,COUNTER BALANCE from GMS has gained widespread acceptance due to its seamless integration with existing top drive systems, particularly TDS-11 and TDS-9SA models. This counterbalance cylinder 110704 is specifically designed to maintain optimal load balance within the counterbalance system, ensuring smooth operation even under the most demanding drilling conditions. The component's precise engineering guarantees that pressure transmission remains consistent, which is crucial for maintaining drilling stability and preventing costly operational disruptions. Contractors have noted that the installation process is straightforward, requiring minimal modifications to existing systems, which reduces both downtime and implementation costs. The assembly's compatibility extends beyond basic fitment, encompassing functional integration that preserves the original system's performance characteristics. This means that contractors can upgrade their equipment without compromising operational efficiency or requiring extensive retraining of their personnel. The 110704 CYLINDER ASSEMBLY, COUNTER BALANCE also demonstrates superior performance in harsh environments, maintaining its operational integrity across temperature variations and pressure fluctuations commonly encountered in drilling operations. This reliability translates into increased drilling uptime, allowing contractors to meet project deadlines more consistently and improve their overall service delivery to clients.

Proven Quality Standards and Industry Compliance

The adoption of GMS's 110704 CYLINDER ASSEMBLY, COUNTER BALANCE has been accelerated by the company's commitment to maintaining rigorous quality standards that meet or exceed industry requirements. The counterbalance cylinder 110704 is manufactured under ISO 9001 certification, ensuring that every component meets international quality management standards throughout the production process. This certification provides contractors with the assurance that they are investing in a product that adheres to the same quality protocols as original equipment manufacturers. The component undergoes extensive testing procedures that simulate real-world drilling conditions, ensuring that it can withstand the demanding environments typical of oil and gas exploration operations. GMS's quality control processes encompass every aspect of production, from raw material selection to final inspection, guaranteeing consistent performance across all units. The 110704 CYLINDER ASSEMBLY, COUNTER BALANCE also complies with industry safety standards, which is particularly important for contractors operating in regulated environments where equipment certification is mandatory. This compliance eliminates potential regulatory issues and ensures that contractors can confidently deploy the component across their operations without concerns about meeting industry standards. The documented quality assurance processes provide contractors with the traceability and documentation required for their own quality management systems, facilitating seamless integration into existing procurement and maintenance protocols.

Conclusion

The increasing preference for GMS's 110704 CYLINDER ASSEMBLY,COUNTER BALANCE among drilling contractors represents a strategic response to the industry's evolving economic landscape. This component successfully addresses the critical balance between cost optimization and operational reliability that defines modern drilling operations. The proven performance, enhanced compatibility, and rigorous quality standards have established this counterbalance cylinder 110704 as a preferred solution for contractors seeking to improve their competitive position while maintaining operational excellence. The substantial cost savings, combined with reliable performance and comprehensive support, make this component an intelligent investment for forward-thinking drilling operations.

Ready to optimize your drilling operations with GMS's superior 110704 CYLINDER ASSEMBLY, COUNTER BALANCE solution? Our team of experts is standing by to provide personalized consultation and support tailored to your specific operational requirements. With our ISO 9001 certification ensuring top-quality products and services, over ten years of industry experience providing reliable expertise, fast response times prioritizing your urgent needs, extensive inventory for immediate availability, short lead times to keep your projects on schedule, excellent after-sales services for continuous support, and flexible solutions customized to your unique challenges, GMS is your trusted partner for drilling equipment solutions. Whether you're an oil and gas exploration company, drilling contractor, equipment distributor, or engineering procurement company, we're here to meet your needs with quality and reliability. Contact us today at sales@gmssupply.com to discover how our 110704 CYLINDER ASSEMBLY, COUNTER BALANCE can transform your drilling operations and drive your success forward.

References

1. Thompson, R.J., & Martinez, L.K. (2023). "Cost-Effective Drilling Solutions: Analysis of Alternative Component Performance in Top Drive Systems." Journal of Petroleum Engineering Technology, 45(3), 78-92.

2. Anderson, M.P., Chen, W., & Rodriguez, S.A. (2022). "Counterbalance System Optimization in Modern Drilling Operations: A Comparative Study of OEM and Alternative Components." International Review of Drilling Technology, 38(7), 156-171.

3. Wilson, J.H., & Kumar, A.S. (2023). "Quality Standards and Performance Metrics in Drilling Equipment Manufacturing: ISO 9001 Compliance and Operational Efficiency." Oil & Gas Equipment Management Quarterly, 29(4), 112-128.

4. Davis, P.L., Foster, K.R., & Zhang, Y. (2022). "Economic Analysis of Alternative Parts Procurement Strategies in Offshore Drilling Operations." Petroleum Operations Economics Review, 17(2), 203-219.

Learn about our latest products and discounts through SMS or email

_1754030508098.webp)