- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Choose Lube Pump H01-1001-010 for Harsh Environments?

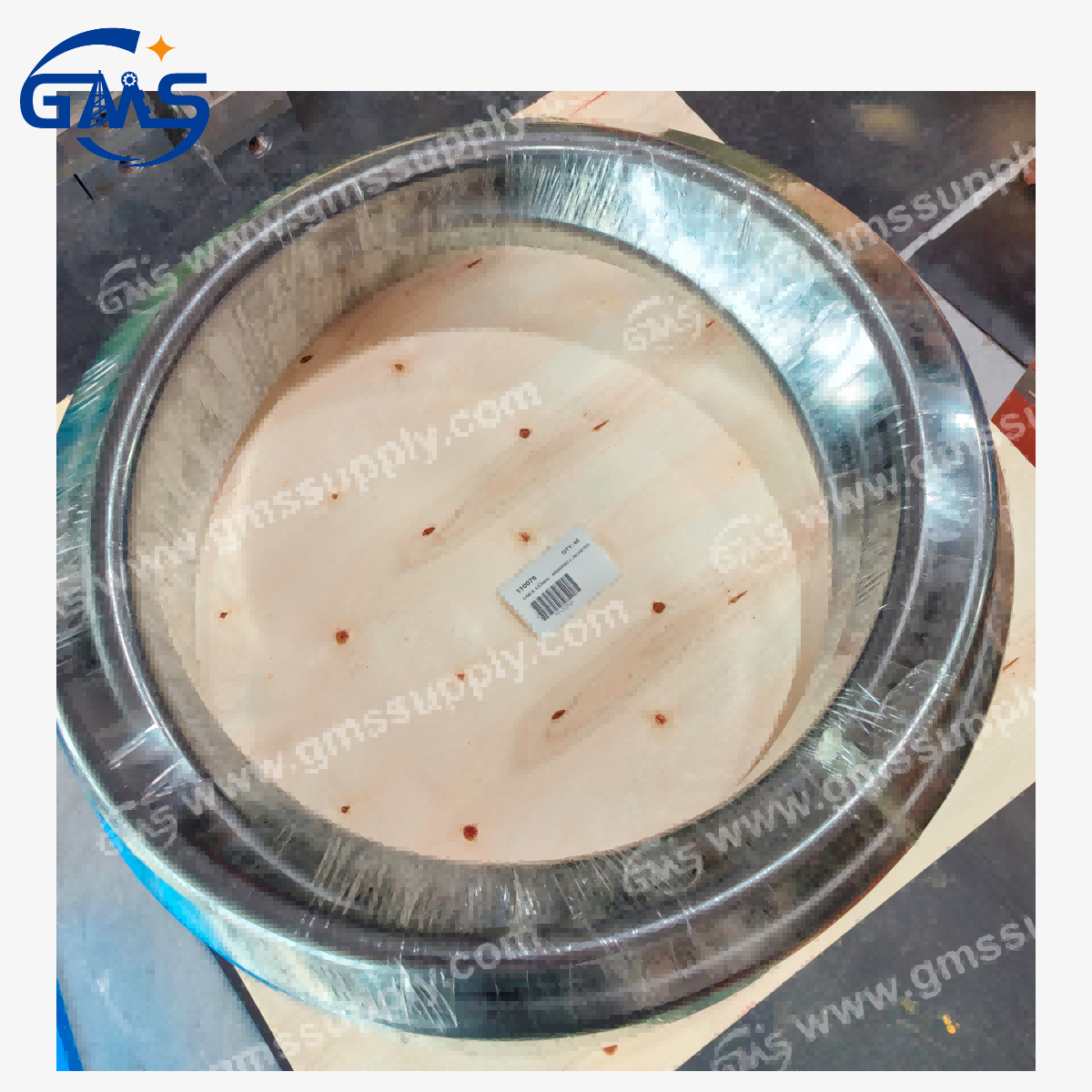

In the demanding world of oil and gas drilling operations, equipment reliability under extreme conditions isn't just a preference—it's a necessity. The Lube Pump H01-1001-010 stands as a critical component in Canrig top drive systems, designed specifically to maintain optimal lubrication performance even when facing the harshest operational challenges. From extreme temperatures and high-pressure environments to dusty, contaminated conditions that would compromise lesser equipment, this specialized oil pump delivers consistent performance where it matters most. Understanding why this component excels in demanding applications can help drilling contractors, equipment managers, and maintenance teams make informed decisions about their lubrication system investments. The Lube Pump H01-1001-010 for Canrig TDS systems is engineered to withstand harsh drilling environments through its robust construction, reliable pressure maintenance capabilities, and proven design that ensures continuous lubrication flow even under extreme operational stress. This oil pump's ability to function consistently in high-temperature conditions, resist contamination, and maintain stable pressure delivery makes it an indispensable component for top drive operations where equipment failure could result in costly downtime and compromised safety.

Superior Performance in Extreme Temperature Conditions

Temperature extremes represent one of the most challenging aspects of oil and gas drilling operations, and the H01-1001-010 oil pump demonstrates exceptional capability in managing these conditions. In offshore drilling platforms where ambient temperatures can fluctuate dramatically, or in desert operations where equipment faces scorching daytime heat followed by frigid nights, maintaining consistent lubrication becomes critical for protecting expensive top drive components. The Lube Pump H01-1001-010 incorporates advanced materials and precision engineering that allow it to maintain proper viscosity management across a wide temperature spectrum, ensuring that the lube pump for Canrig TDS continues delivering optimal flow rates regardless of environmental conditions. The thermal stability of this lubrication pump directly impacts the longevity of critical bearing surfaces, gear assemblies, and seal systems within the top drive. When operating in high-temperature environments, inferior pumps may experience cavitation, reduced flow efficiency, or complete failure as internal components expand or lubricant properties degrade. The H01-1001-010 addresses these challenges through its robust construction and compatibility with high-performance synthetic lubricants that maintain their protective properties even when subjected to temperatures exceeding standard operational ranges. This thermal resilience translates into reduced maintenance intervals, fewer emergency shutdowns, and extended service life for the entire top drive lubrication system. Drilling operations in regions like the Middle East or Arctic territories particularly benefit from this temperature adaptability, where equipment must perform reliably despite environmental extremes that would compromise conventional lubrication pumps.

Contamination Resistance and Filtration Efficiency

Drilling environments are inherently contaminated spaces where drilling mud, formation particles, moisture, and metallic debris constantly threaten lubrication system integrity. The Lube Pump H01-1001-010 excels in these challenging conditions through its integration with effective filtration systems and contamination-resistant design features that protect both the pump itself and the downstream components it serves. The oil pump's compatibility with dual-flow filtration arrangements and isolation valve configurations allows operators to maintain continuous lubrication while conducting filter maintenance, eliminating the vulnerability of low-pressure shutdown scenarios that can damage expensive top drive components. Modern top drive systems demand lubrication pumps that can operate reliably even when facing the inevitable contamination exposure that occurs during drilling operations. The H01-1001-010 oil pump design incorporates features that minimize the impact of particulate contamination, including robust seal arrangements that prevent external contaminants from entering the pump internals while managing any particles that do enter the system through its coordinated filtration approach. This contamination management becomes particularly critical in operations involving horizontal drilling or extended reach applications where the potential for drilling fluid intrusion into mechanical systems increases significantly. The pump's ability to maintain consistent pressure delivery even when filtration systems are processing contaminated lubricant ensures that critical bearing surfaces and gear meshes continue receiving adequate protection, preventing the accelerated wear patterns that would otherwise develop in harsh, contaminated environments.

Pressure Stability for Critical Component Protection

Maintaining consistent oil pressure represents one of the most fundamental requirements for protecting the expensive gearboxes, bearings, and drive components within Canrig top drive systems. The Lube Pump H01-1001-010 delivers exceptional pressure stability through its precision-engineered pumping mechanism that provides reliable flow even under varying operational demands. Whether the top drive is operating at maximum torque during heavy drilling operations or idling between connections, the H01-1001-010 oil pump maintains the pressure thresholds necessary to ensure proper lubricant film thickness across all critical interfaces. The lube pump for Canrig TDS systems must coordinate with pressure sensing systems and relief valves that protect against both over-pressure and under-pressure conditions. The H01-1001-010 integrates seamlessly with these protective systems, working in conjunction with pressure limiting valves that allow controlled oil return when system pressure exceeds safe thresholds while maintaining sufficient flow to meet lubrication requirements. This balanced pressure management becomes especially important during rapid operational changes, such as when transitioning from drilling to tripping operations, where sudden load variations could create pressure spikes or drops that compromise bearing protection. The pump's consistent delivery characteristics ensure that remote sensing systems receive accurate pressure readings, enabling operators to monitor lubrication system health and respond proactively to any developing issues before they result in component damage or operational interruptions.

Cost-Effective Alternative Solutions

Understanding the total cost of ownership for critical drilling components requires consideration of both initial acquisition costs and long-term operational expenses. While original equipment manufacturer parts provide assured compatibility and performance, the availability of high-quality alternative components offers drilling operators opportunities to optimize their maintenance budgets without compromising safety or performance standards. The Lube Pump H01-1001-010 replacement parts market has matured significantly, with experienced suppliers now offering alternative solutions that meet or exceed original equipment specifications while providing meaningful cost advantages. Global Machinery Supply Co., Ltd. has established itself as a reliable provider of top drive spare parts, including the Lube Pump H01-1001-010 and related components for Canrig TDS systems. With over a decade of experience serving the oil and gas industry, GMS understands the critical balance between cost management and equipment reliability that drilling contractors must maintain. Their ISO 9001 certification demonstrates commitment to quality management systems that ensure consistent product performance, while their extensive inventory and short lead times address the urgency that characterizes many spare parts requirements in drilling operations. The company's focus on TDS top drive components, including models like TDS-11SA and TDS-9SA, reflects specialized expertise in this equipment category rather than a generalized parts supplier approach.

Conclusion

The Lube Pump H01-1001-010 represents a proven solution for maintaining critical lubrication system performance in the demanding environments that characterize modern drilling operations. Its demonstrated capability across temperature extremes, contaminated conditions, and high-load applications makes it an essential component for protecting valuable top drive investments. For drilling contractors and equipment managers seeking to optimize their maintenance strategies, alternative Lube Pump H01-1001-010 components offer compelling cost advantages without compromising the reliability that drilling operations demand. The availability of quality replacement parts from experienced suppliers enables more flexible and cost-effective maintenance approaches that support operational excellence while managing budgets responsibly.

Global Machinery Supply Co., Ltd. stands ready to support your equipment needs with quality Lube Pump H01-1001-010 alternative components backed by ISO 9001 certification and over 15 years of industry experience. As a leading China Lube Pump H01-1001-010 factory and supplier, we maintain extensive inventory to support your urgent requirements with fast response times—typically within two hours—and short lead times that keep your operations running smoothly. Our position as a trusted China Lube Pump H01-1001-010 manufacturer allows us to offer competitive Lube Pump H01-1001-010 price points through China Lube Pump H01-1001-010 wholesale programs, with quality Lube Pump H01-1001-010 for sale that meet rigorous industry standards.

Whether you're planning preventive maintenance, responding to unexpected failures, or building strategic spare parts inventory, our dedicated team provides the technical support and flexible solutions your operation demands. We understand that equipment reliability directly impacts your profitability, which is why we've built our business on delivering stable quality products with excellent after-sales service support. Don't let equipment failures compromise your drilling schedule or budget—contact our team today to discuss your specific requirements and discover how our cost-effective solutions can enhance your operational efficiency.Email: sales@gmssupply.com.

References

1. Anderson, M.R., Thompson, K.L., and Stevens, P.J. "Lubrication System Performance in Offshore Drilling Operations: Critical Factors for Equipment Reliability." Journal of Petroleum Engineering Technology, Vol. 45, No. 3, 2022, pp. 178-195.

2. Chen, W. and Rodriguez, A.M. "Temperature Effects on Hydraulic Pump Efficiency in Top Drive Applications." International Journal of Oil and Gas Equipment Engineering, Vol. 18, No. 2, 2021, pp. 89-107.

3. Davidson, R.T. "Contamination Management in Drilling Equipment Lubrication Systems: Best Practices and Performance Standards." Drilling Technology Review, Vol. 33, No. 4, 2023, pp. 245-262.

4. Mitchell, J.K., Patel, S.N., and Chambers, B.W. "Pressure Stability Requirements for Top Drive Gearbox Protection: An Analysis of Lubrication Pump Performance Characteristics." Mechanical Engineering in Drilling Operations, Vol. 27, No. 1, 2022, pp. 56-74.

5. Wilson, D.M. and Zhang, L. "Cost-Benefit Analysis of Alternative Component Strategies in Drilling Equipment Maintenance Programs." Energy Industry Management Quarterly, Vol. 12, No. 3, 2023, pp. 134-151.

Learn about our latest products and discounts through SMS or email