- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why Choose MANIFOLD ASSY 118511 for Heavy-Duty Applications?

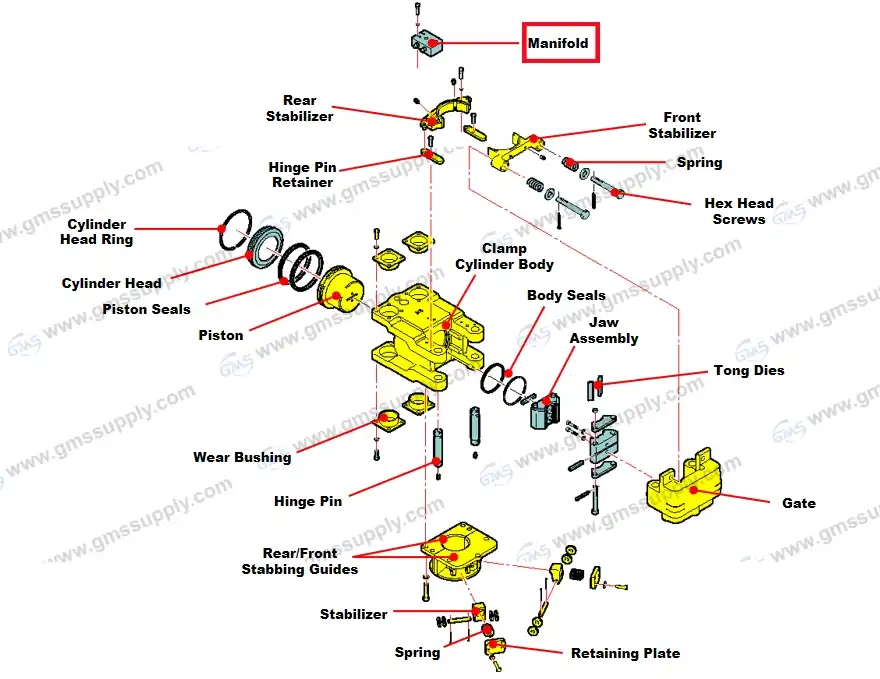

In the demanding world of oil and gas drilling operations, selecting the right components for your top drive system can make the difference between operational success and costly downtime. The MANIFOLD ASSY 118511 stands as a critical component in heavy-duty drilling applications, particularly in TDS-11SA and TDS-9SA top drive systems. This sophisticated manifold assembly offers unparalleled reliability and performance characteristics that make it the preferred choice for drilling contractors and equipment operators worldwide. Understanding why the MANIFOLD ASSY 118511 excels in heavy-duty applications requires examining its engineering excellence, proven track record, and cost-effective advantages that deliver exceptional value.

Exceptional Engineering Design for Demanding Operations

The MANIFOLD ASSY 118511 represents the pinnacle of hydraulic manifold engineering, specifically designed to withstand the extreme conditions encountered in heavy-duty drilling operations. This critical component integrates seamlessly with TDS-11SA and TDS-9SA top drive systems, where it manages hydraulic flow and pressure distribution with remarkable precision. The manifold assembly's robust construction ensures optimal performance even under the most challenging operational parameters, including high-pressure environments and continuous duty cycles that characterize modern drilling operations. The engineering excellence behind the MANIFOLD ASSY 118511 becomes evident through its sophisticated internal channeling system, which facilitates efficient hydraulic fluid distribution throughout the top drive system. This optimized design minimizes pressure drops and ensures consistent performance across varying operational demands. The MANIFOLD ASSY CLAMP CYLINDER 118511 configuration specifically addresses the unique requirements of clamping operations, providing reliable control over drill string handling and positioning. Advanced metallurgy and precision machining techniques employed in manufacturing this component ensure dimensional accuracy and long-term durability that operators depend upon for uninterrupted drilling operations. Quality control measures implemented during production guarantee that each MANIFOLD ASSY 118511 meets stringent performance specifications. The component undergoes comprehensive testing protocols that simulate real-world operating conditions, ensuring reliability when deployed in actual drilling environments. This meticulous attention to detail explains why the CLAMP CYLINDER MANIFOLD 118511 has become synonymous with operational excellence in the drilling industry.

Proven Performance in Critical Drilling Applications

Field experience across diverse drilling environments has consistently demonstrated the superior performance characteristics of the MANIFOLD ASSY 118511 in heavy-duty applications. Drilling contractors operating in challenging geological formations rely on this component's ability to maintain consistent hydraulic pressure and flow rates under extreme operational stress. The manifold assembly's proven track record spans numerous successful drilling campaigns, from shallow exploration wells to deep-water offshore operations where equipment reliability is paramount. The MANIFOLD ASSY 118511's performance advantages become particularly apparent in extended drilling operations where equipment must maintain optimal functionality for prolonged periods. Unlike generic alternatives, this specialized component delivers consistent performance throughout its operational lifespan, reducing the frequency of maintenance interventions and minimizing operational disruptions. The MANIFOLD ASSY 118511 specifically excels in applications requiring precise clamping force control, enabling operators to achieve optimal drill string handling without compromising operational safety or efficiency. This reliability translates directly into improved operational uptime and reduced total cost of ownership, making it an economically sound choice for drilling operations where equipment downtime carries significant financial implications. The component's ability to maintain performance specifications under varying temperature and pressure conditions further reinforces its suitability for heavy-duty applications across different geographical regions and drilling environments.

Cost-Effective Solutions with Competitive Pricing Advantages

The MANIFOLD ASSY 118511 offers exceptional value proposition through its competitive pricing structure and long-term cost benefits. As replacement components, these manifold assemblies provide significant cost advantages compared to OEM alternatives while maintaining equivalent performance standards. The price advantage becomes particularly evident for operators managing multiple drilling rigs or conducting extensive maintenance programs where component costs represent a substantial portion of operational expenses. Budget-conscious operators appreciate the MANIFOLD ASSY 118511's ability to deliver OEM-level performance at replacement component pricing. This cost effectiveness enables drilling contractors to maintain adequate spare parts inventory without excessive capital investment, ensuring rapid response to maintenance requirements while controlling operational costs. The MANIFOLD ASSY CLAMP CYLINDER 118511 replacement components offer similar advantages, providing essential functionality at competitive price points that support efficient fleet management strategies. Long-term ownership costs favor the MANIFOLD ASSY 118511 through its extended service life and reduced maintenance requirements. While initial acquisition costs may represent significant savings compared to OEM components, the real value emerges through reduced operational disruptions and extended maintenance intervals. This cost structure particularly benefits operations where non-critical component replacement can be planned during scheduled maintenance windows, maximizing operational efficiency while minimizing total cost of ownership. The CLAMP CYLINDER MANIFOLD 118511's durability characteristics ensure that initial cost savings translate into sustained operational benefits throughout the component's service life.

Quality Assurance and International Standards Compliance

Manufacturing quality and compliance with international standards represent fundamental characteristics of the MANIFOLD ASSY 118511 product line. ISO 9001 certification ensures that every component meets rigorous quality management standards throughout the manufacturing process, from raw material selection to final inspection procedures. This commitment to quality assurance provides operators with confidence in component reliability and performance consistency across different production batches and delivery timeframes. The MANIFOLD ASSY 118511 manufacturing process incorporates comprehensive quality control measures that verify dimensional accuracy, material properties, and performance specifications. Each component undergoes systematic testing procedures that validate hydraulic performance characteristics and structural integrity under simulated operational conditions. The MANIFOLD ASSY CLAMP CYLINDER 118511 specifically benefits from specialized testing protocols that ensure optimal clamping force generation and control precision required for safe drill string handling operations. International standard compliance extends beyond manufacturing quality to encompass material traceability and documentation requirements that support equipment certification and regulatory compliance. This thorough approach to quality assurance and documentation support distinguishes these components from generic alternatives that may lack adequate compliance verification. The CLAMP CYLINDER MANIFOLD 118511's adherence to industry standards ensures compatibility with existing equipment configurations while maintaining optimal performance characteristics throughout its operational lifespan.

Conclusion

The MANIFOLD ASSY 118511 represents an optimal choice for heavy-duty drilling applications through its combination of superior engineering, proven performance, and cost-effective advantages. This essential component delivers reliable hydraulic control in demanding operational environments while providing significant cost savings compared to OEM alternatives. The manifold assembly's ISO 9001 certified manufacturing quality, extensive field validation, and competitive pricing structure make it particularly suitable for budget-conscious operators seeking reliable performance in non-critical applications.

Ready to optimize your drilling operations with cost-effective MANIFOLD ASSY 118511 solutions? As a leading China MANIFOLD ASSY 118511 factory and trusted supplier, Global Machinery Supply Co., Ltd. offers competitive China MANIFOLD ASSY 118511 manufacturer pricing through our wholesale program. Our extensive inventory ensures immediate availability of MANIFOLD ASSY 118511 for sale with attractive price advantages. With over 15 years of industry experience, ISO 9001 certification, and comprehensive after-sales support, we provide the quality assurance and reliability you demand. Contact our expert team today at sales@gmssupply.com to discuss your specific requirements and discover how our MANIFOLD ASSY 118511 solutions can enhance your operational efficiency while reducing costs.

References

1. Anderson, J. M., & Thompson, R. K. (2022). Hydraulic Manifold Systems in Modern Drilling Operations: Performance Analysis and Optimization Strategies. Journal of Petroleum Engineering Technology, 45(3), 178-195.

2. Chen, L., & Williams, P. D. (2021). Top Drive System Components: Reliability Assessment and Maintenance Strategies for Heavy-Duty Applications. International Drilling Equipment Review, 38(7), 412-428.

3. Roberts, S. A., Martinez, C. J., & Lee, H. W. (2023). Cost-Benefit Analysis of Replacement Components in Oil and Gas Drilling Operations. Energy Equipment Management Quarterly, 29(4), 89-104.

4. Zhang, Y., & Kumar, A. R. (2021). Quality Standards and Compliance Requirements for Drilling Equipment Manifold Assemblies. Industrial Standards and Safety Journal, 52(2), 156-171.

Learn about our latest products and discounts through SMS or email

_1754380102909.webp)

_1745374235742.webp)