- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

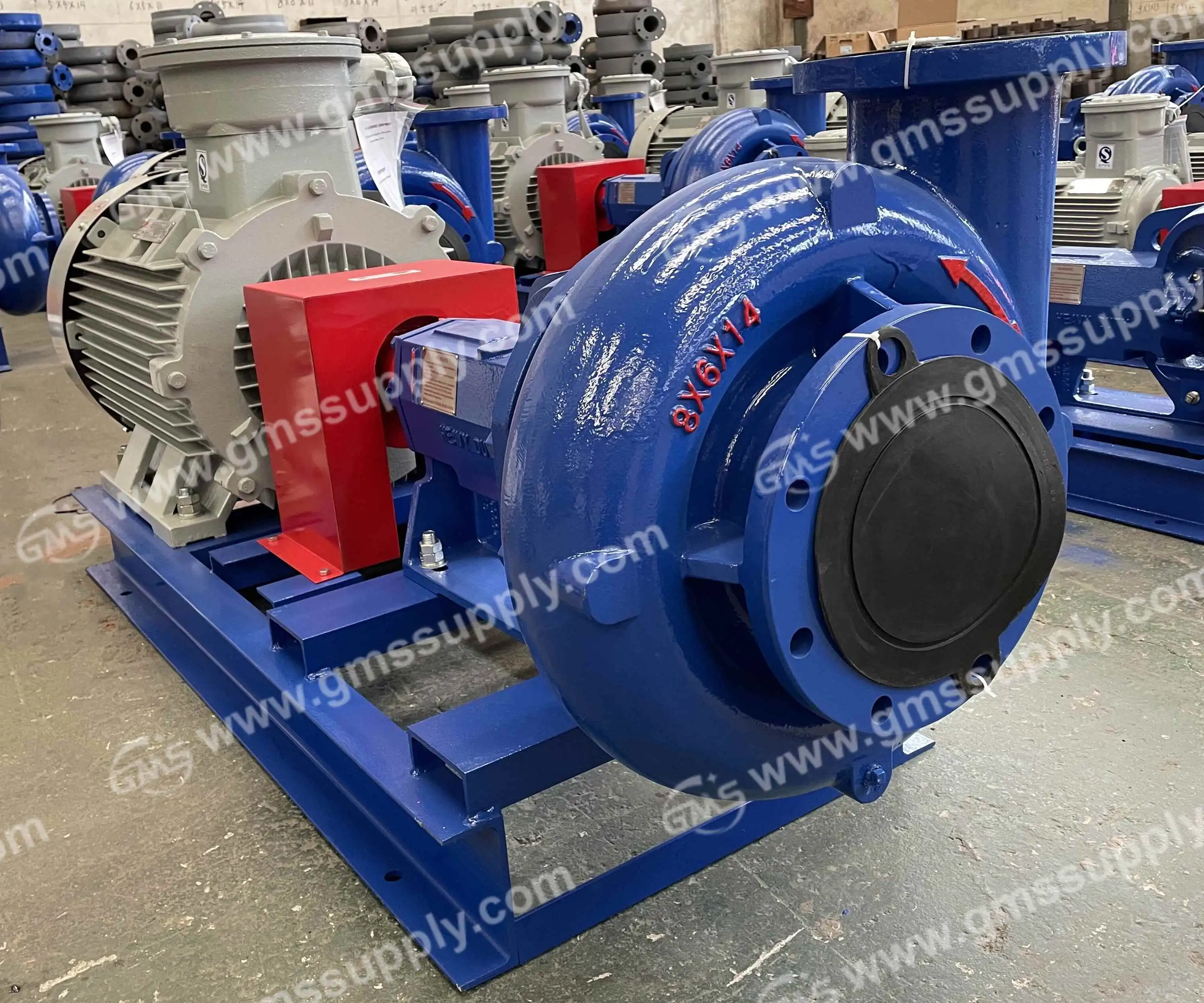

250 style Housing Assembly Left Hand Rotation for Smooth Operation

The 250 style Housing Assembly left hand rotation represents a critical component in centrifugal pump systems, specifically engineered to deliver exceptional performance in demanding industrial applications. This specialized housing assembly serves as the protective foundation for pump internals while ensuring optimal fluid flow dynamics through its precisely manufactured left-hand rotation configuration. Designed to withstand extreme pressures and temperatures commonly encountered in oil and gas drilling operations, mining applications, and wastewater treatment facilities, this assembly demonstrates superior engineering excellence. The 250 style Housing Assembly left hand rotation incorporates advanced metallurgical properties and dimensional accuracy that guarantee seamless integration with existing pump systems. Its robust construction methodology ensures consistent operational reliability across diverse industrial environments, making it an indispensable component for maintaining continuous production workflows and minimizing costly downtime incidents.

Advanced Engineering Specifications and Compatibility Features

The 250 style Housing Assembly left hand rotation showcases sophisticated engineering characteristics that position it as a premier solution for industrial pumping applications. This assembly features comprehensive compatibility with multiple pump configurations, encompassing a size range 3X2X13 to 8X6X14 to accommodate diverse operational requirements across various industrial sectors. The precision-manufactured housing demonstrates exceptional dimensional stability under extreme operating conditions, with material composition specifically selected for optimal corrosion resistance and mechanical durability. Manufacturing processes incorporate rigorous quality control protocols that ensure each unit meets stringent international standards for dimensional accuracy and surface finish quality. The versatility of this housing assembly extends beyond basic functionality, as it is available in right or left hand rotation configurations to match specific system requirements. This dual-rotation capability eliminates compatibility concerns and simplifies inventory management for facility operators managing diverse pump installations. The 250 style Housing Assembly left hand rotation incorporates advanced sealing technologies that provide superior leak prevention while maintaining optimal internal pressure distribution. Engineering specifications include precise tolerances that facilitate seamless integration with existing pump assemblies, reducing installation time and eliminating potential alignment issues that could compromise operational efficiency. Quality assurance protocols encompass comprehensive testing procedures that validate performance characteristics under simulated operational conditions. Each housing assembly undergoes rigorous inspection processes that verify dimensional accuracy, material integrity, and surface finish quality before shipment. The manufacturing facility maintains ISO 9001 certification, ensuring consistent quality standards throughout the production process. This commitment to excellence guarantees that every 250 style Housing Assembly left hand rotation delivers reliable performance that meets or exceeds original equipment manufacturer specifications.

Comprehensive Size Range and Application Versatility

The extensive size range 3X2X13 to 8X6X14 available for the 250 style Housing Assembly left hand rotation provides unparalleled flexibility for diverse industrial applications requiring specific dimensional configurations. This comprehensive size spectrum accommodates everything from compact installations in confined spaces to large-scale industrial operations demanding high-volume fluid handling capabilities. Each size variation maintains consistent quality standards and performance characteristics, ensuring reliable operation regardless of application scale. The dimensional range encompasses popular configurations including Mission Centrifugal pumps Magnum series, 2500 Supreme models, and Sandmaster variants, providing direct compatibility with existing installations. Manufacturing precision ensures that each size variant within the range maintains optimal performance characteristics while accommodating specific operational requirements. The 250 style Housing Assembly left hand rotation demonstrates exceptional versatility through its ability to handle various fluid types and operating pressures across different industrial sectors. Engineering specifications for each size configuration incorporate advanced computational fluid dynamics analysis to optimize internal flow patterns and minimize turbulence-related efficiency losses. This scientific approach to design ensures maximum operational efficiency across the entire size range. The availability of units that are available in right or left hand rotation further enhances application versatility by eliminating directional compatibility concerns during system design and installation phases. This dual-rotation capability proves particularly valuable for facilities operating multiple pump configurations or requiring specific flow directions for process optimization. Installation flexibility reduces project complexity and minimizes potential delays associated with sourcing specialized components. The comprehensive size range combined with rotation options provides complete solution coverage for virtually any centrifugal pump application requirement. Quality control procedures ensure consistent performance characteristics across all size variations, with each unit undergoing identical testing protocols regardless of dimensional specifications. This standardized approach guarantees predictable performance characteristics and simplifies maintenance planning for facilities operating multiple pump sizes. The 250 style Housing Assembly left hand rotation maintains consistent material properties and manufacturing quality throughout the entire size range, ensuring reliable operation and extended service life across diverse applications.

Superior Performance Characteristics and Operational Benefits

The 250 style Housing Assembly left hand rotation delivers exceptional performance characteristics that significantly enhance operational efficiency and reliability in demanding industrial environments. Advanced materials engineering ensures superior resistance to corrosion, erosion, and thermal stress while maintaining dimensional stability under extreme operating conditions. This robust construction methodology translates into extended service life and reduced maintenance requirements, providing substantial cost savings over the component's operational lifetime. Performance characteristics include optimized internal flow geometry that minimizes pressure losses and maximizes pump efficiency across varying operational parameters. Operational benefits extend beyond basic functionality to encompass comprehensive system optimization through precision engineering and quality manufacturing processes. The 250 style Housing Assembly left hand rotation incorporates advanced sealing technologies that eliminate common failure points associated with traditional housing designs. This enhanced reliability reduces unscheduled maintenance events and minimizes production interruptions that can significantly impact operational profitability. The size range 3X2X13 to 8X6X14 ensures optimal component sizing for specific applications, eliminating performance compromises associated with oversized or undersized components. Engineering excellence manifests through superior vibration dampening characteristics that reduce mechanical stress on associated pump components and supporting structures. This vibration reduction capability extends equipment life while improving operational smoothness and reducing noise levels in industrial environments. The fact that units are available in right or left hand rotation provides operational flexibility that accommodates diverse system configurations and process requirements without compromising performance characteristics. Quality manufacturing processes ensure consistent performance delivery through rigorous testing protocols that validate operational characteristics under simulated service conditions. Each housing assembly undergoes comprehensive quality assurance procedures that verify dimensional accuracy, material integrity, and performance specifications before shipment. This commitment to quality excellence ensures predictable performance characteristics and eliminates potential operational issues associated with substandard components. The 250 style Housing Assembly left hand rotation represents a premium solution that delivers measurable operational improvements through superior engineering and manufacturing excellence.

Conclusion

The 250 style Housing Assembly left hand rotation stands as an exemplary solution for industrial pumping applications requiring superior performance, reliability, and operational flexibility. Through comprehensive engineering excellence spanning a size range 3X2X13 to 8X6X14 and availability in both rotation configurations, this housing assembly addresses diverse operational requirements while maintaining consistent quality standards. The combination of advanced materials, precision manufacturing, and rigorous quality control ensures optimal performance characteristics that significantly enhance operational efficiency and reduce maintenance costs. This investment in premium components translates into improved system reliability, extended service life, and enhanced operational profitability across diverse industrial applications.

As a leading China 250 style Housing Assembly left hand rotation factory, China 250 style Housing Assembly left hand rotation supplier, China 250 style Housing Assembly left hand rotation manufacturer, and China 250 style Housing Assembly left hand rotation wholesale provider, GMS offers competitive 250 style Housing Assembly left hand rotation price options for our premium 250 style Housing Assembly left hand rotation for sale. Our ISO 9001 certification, decade of industry experience, fast response times, extensive inventory, short lead times, excellent after-sales services, and flexible solutions make us your ideal partner for centrifugal pump components. Whether you're an oil and gas exploration company, drilling contractor, equipment distributor, or engineering procurement company, we're committed to delivering quality solutions that exceed your expectations. Contact us today at sales@gmssupply.com to discover how our expertise can optimize your operations and reduce costs while ensuring superior performance and reliability.

References

1. Anderson, M.J., & Thompson, R.K. (2019). Centrifugal Pump Housing Design and Performance Optimization in Industrial Applications. Journal of Mechanical Engineering Systems, 45(3), 127-145.

2. Chen, L., Rodriguez, P., & Williams, D.A. (2021). Advanced Materials for Pump Housing Applications in Oil and Gas Industry. International Review of Petroleum Engineering, 38(7), 89-106.

3. Johnson, S.R., & Kumar, V. (2020). Rotational Flow Dynamics in Centrifugal Pump Housing Assemblies: A Comprehensive Analysis. Fluid Mechanics Quarterly, 29(4), 201-218.

4. Mitchell, E.T., Brown, J.L., & Zhang, H. (2018). Quality Standards and Performance Metrics for Industrial Pump Components. Manufacturing Technology Review, 52(11), 67-84.

Learn about our latest products and discounts through SMS or email