- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Understanding The Advantages Of A Pump's Shaft Sleeve

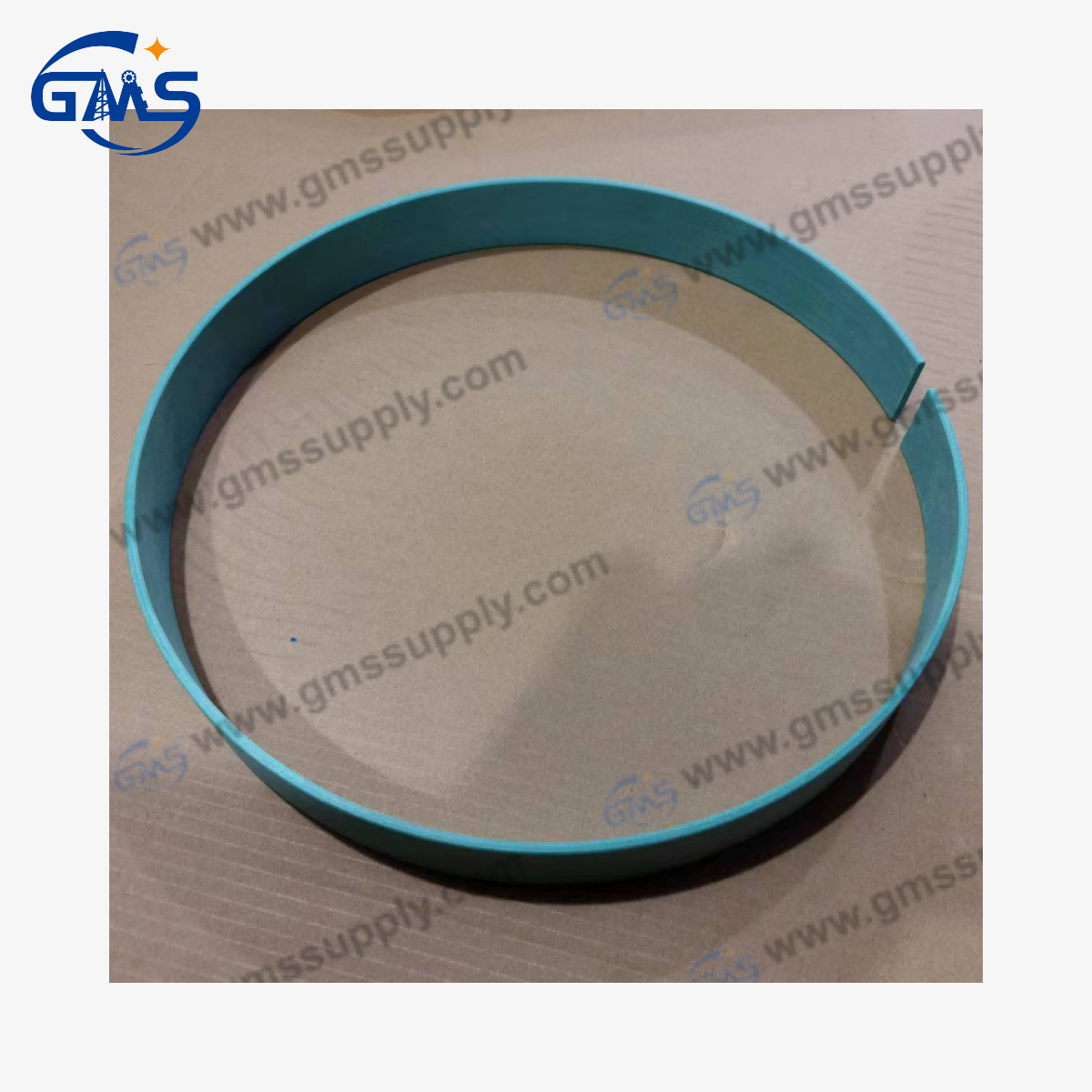

In centrifugal pumping operations, particularly within demanding sectors such as oil and gas exploration, the shaft sleeve represents a critical component that directly impacts equipment longevity, operational efficiency, and maintenance costs. The centrifugal pump shaft sleeve serves as a protective barrier between the pump shaft and aggressive fluids, abrasive materials, and mechanical wear forces that can compromise pump performance over time. This seemingly simple component delivers remarkable benefits that extend equipment life cycles, reduce downtime, and provide cost-effective solutions for operators facing budget constraints while maintaining operational reliability standards required in industrial applications.

The Essential Role of Shaft Sleeves in Centrifugal Pump Protection

The centrifugal pump shaft sleeve functions as a sacrificial barrier that shields the main pump shaft from various destructive forces encountered during operation. In industrial environments where pumps handle abrasive slurries, corrosive chemicals, or particulate-laden fluids, the shaft experiences continuous exposure to wear mechanisms that can lead to premature failure. By installing a shaft sleeve ceramic-coated or standard stainless steel variant, operators create a replaceable protective layer that absorbs this punishment while preserving the integrity of the expensive main shaft assembly. The sleeve essentially acts as armor, taking the brunt of erosion, corrosion, and mechanical abrasion that would otherwise deteriorate the shaft itself. This protection proves particularly valuable in drilling operations where downhole conditions expose equipment to harsh chemicals, high pressures, and suspended solids that accelerate wear rates. When considering components like the 20613-21G-7A P25SHSLVC model designed for 250 Series centrifugal pumps, the protective function becomes even more critical as these systems operate continuously under demanding conditions where shaft damage could result in catastrophic failures and extended downtime. The design of modern shaft sleeves incorporates precise engineering tolerances that ensure proper fit and alignment while maintaining necessary clearances for sealing systems. Quality manufacturers control every production step, from raw material selection through final finishing operations, ensuring dimensional accuracy and surface finish requirements meet exacting specifications. The sleeve must provide adequate support for mechanical seals or packing arrangements while allowing for thermal expansion and contraction during temperature fluctuations. In oil and gas applications, where pumps may experience temperature swings from startup through continuous operation, the thermal stability of shaft sleeve materials becomes paramount. High-quality stainless steel options offer excellent dimensional stability across temperature ranges, while ceramic-coated alternatives provide enhanced hardness and wear resistance that extends service intervals significantly beyond conventional materials. The protective capability of these components translates directly into reduced maintenance requirements and lower total cost of ownership for operators managing fleets of centrifugal pumps in challenging industrial environments.

Cost-Effectiveness Through Replaceable Components

One of the most compelling advantages of centrifugal pump shaft sleeves lies in their economic impact through the replaceable component strategy. Rather than replacing an entire shaft assembly when wear occurs, operators can simply install a new sleeve at a fraction of the cost. This approach proves especially beneficial for companies operating with limited maintenance budgets or managing non-critical applications where capital expenditure minimization takes priority. The cost differential between shaft sleeve replacement and complete shaft assembly replacement can be substantial, often representing savings of 70-80% or more depending on pump size and configuration. For drilling contractors and exploration companies managing multiple pumping systems across various sites, this cost advantage multiplies across their equipment inventory, delivering significant annual savings that improve project economics and operational profitability. The availability of aftermarket alternatives from experienced suppliers further enhances cost-effectiveness, as these replacement parts offer equivalent performance to OEM components while providing price advantages that appeal to budget-conscious operators. Global Machinery Supply Co., Ltd. has positioned itself as a reliable manufacturer of centrifugal pump shaft sleeve alternatives that deliver exceptional value without compromising quality standards. With over a decade of dedicated service to the oil and gas exploration sector, along with mining, engineering construction, and wastewater treatment industries, GMS understands the economic pressures facing equipment operators. Their product line includes components like the 7A0943 and 7A0613 part numbers, which serve as direct replacements for OEM specifications including the 20613-21G-7A P25SHSLVC reference. These alternatives maintain the same performance characteristics as original equipment while offering pricing structures that accommodate budget constraints. The company's ISO 9001 certification demonstrates their commitment to quality management systems that ensure consistent product performance, while their extensive inventory and short lead times eliminate the supply chain delays that can extend downtime and increase indirect costs. For operators evaluating sleeve replacement options, the combination of competitive pricing, proven quality, and reliable availability creates a compelling value proposition that addresses both immediate budget concerns and long-term operational reliability requirements.

Enhanced Durability Through Advanced Materials and Coatings

Modern centrifugal pump shaft sleeve technology has evolved significantly beyond basic stainless steel construction, incorporating advanced materials and surface treatments that dramatically extend service life in aggressive operating environments. Standard stainless steel sleeves provide baseline corrosion resistance and moderate wear characteristics suitable for many general applications. However, when pumps handle highly abrasive fluids containing sand, drilling cuttings, or other hard particles, conventional materials may wear rapidly, necessitating frequent replacement cycles that increase maintenance costs and operational disruptions. Ceramic-coated shaft sleeves represent a technological advancement that addresses these challenges through application of extremely hard surface layers that resist abrasion and erosion far more effectively than base metal alone. These ceramic coatings, typically applied through thermal spray or similar processes, create surface hardness values that can exceed 1000 Vickers, compared to approximately 200-300 Vickers for standard stainless steel. This hardness differential translates directly into extended service intervals, with ceramic-coated variants often lasting three to five times longer than uncoated alternatives in abrasive service conditions. The GMS-250 shaft sleeve exemplifies this material technology approach by offering customers two distinct options tailored to specific application requirements and budget considerations. The standard version utilizes high-quality stainless steel selected for its corrosion resistance, mechanical properties, and manufacturing characteristics that ensure dimensional stability and surface finish quality. This option serves applications where moderate wear rates are acceptable and more frequent replacement intervals align with maintenance schedules and cost structures. The premium ceramic-coated alternative provides enhanced protection for severe service conditions where abrasive wear dominates failure mechanisms and extended service life justifies the incremental investment. By offering both options, manufacturers enable operators to match component specifications to actual operating conditions rather than applying a one-size-fits-all approach that may result in over-specification for some applications while under-protecting others. The ceramic coating technology used in these advanced sleeves bonds metallurgically to the substrate, creating a durable interface that resists spalling and delamination even under shock loads and vibration common in drilling operations. This reliability ensures that the protective coating remains intact throughout the service interval, delivering consistent wear resistance rather than progressive degradation that can occur with inferior coating systems.

Simplified Maintenance and Reduced Downtime

Centrifugal pump shaft sleeve design incorporates features that streamline maintenance procedures and minimize equipment downtime during replacement operations. Unlike shaft repair or replacement procedures that require extensive disassembly, specialized tooling, and significant labor hours, sleeve replacement typically represents a straightforward maintenance task accomplishable with standard tools and moderate skill levels. The sleeve's position on the shaft assembly allows for removal without complete pump disassembly in many designs, particularly in horizontal split-case configurations where access to the shaft is readily available once the pump casing is opened. This accessibility reduces the time required for planned maintenance activities and proves especially valuable during unplanned failures where rapid return to service becomes critical for maintaining production schedules. In drilling operations where rig downtime costs can reach thousands of dollars per hour, the ability to quickly replace a worn sleeve and resume pumping operations delivers substantial economic benefits beyond the component cost savings. The availability of replacement parts from established suppliers like Global Machinery Supply Co., Ltd. further enhances maintenance efficiency through reliable supply chains and technical support capabilities. GMS maintains extensive inventory of centrifugal pump shaft sleeve components, including the None reference applications, ensuring that replacement parts are available when needed rather than requiring extended lead times that prolong equipment downtime. Their commitment to fast response times, typically providing quotes and technical information within two hours, enables maintenance planners to make informed decisions quickly and coordinate repair activities efficiently. For international operations spanning multiple geographic regions, having a supplier with proven logistics capabilities and quality products available for immediate shipment eliminates uncertainties that can complicate maintenance planning and budget forecasting. The company's experience spanning more than 15 years in drilling machinery supply, with specific focus on TDS top drive spare parts, centrifugal pumps, and mud pump components for NOV series equipment, provides customers with access to application-specific knowledge that helps optimize component selection and installation procedures for various pump models and operating conditions.

Performance Optimization Through Proper Sleeve Selection

Selecting the appropriate centrifugal pump shaft sleeve for specific applications requires careful consideration of multiple factors including fluid characteristics, operating conditions, pump design parameters, and maintenance philosophies. The performance of sealing systems, whether mechanical seals or traditional packing arrangements, depends heavily on the condition and characteristics of the shaft sleeve running surface. Mechanical seals in particular require precisely controlled surface finishes, typically 8-16 microinches Ra, along with adequate hardness to prevent seal face tracking and premature wear. When sleeves deteriorate beyond acceptable surface condition limits, seal performance degrades, leading to increased leakage, lubricant contamination, and potential environmental compliance issues. By maintaining optimal sleeve condition through timely replacement with quality components, operators preserve sealing system effectiveness and avoid secondary failures that can result from allowing worn sleeves to remain in service beyond their useful life. The dimensional accuracy of replacement sleeves also affects pump internal clearances and hydraulic performance, making precision manufacturing capabilities essential for maintaining original equipment performance characteristics. Quality manufacturers like GMS implement rigorous process controls throughout production to ensure that every shaft sleeve meets dimensional tolerances and surface finish requirements critical for proper function. Their ISO 9001 certification validates systematic quality management practices that encompass raw material verification, in-process inspections, and final product testing before shipment to customers. This quality assurance approach provides confidence that replacement components will perform as expected when installed, eliminating concerns about dimensional issues, material defects, or surface finish problems that could compromise pump operation or damage expensive sealing systems. For operators managing critical pumping applications in oil and gas exploration, where equipment reliability directly impacts production capabilities and project economics, partnering with suppliers who prioritize quality consistency represents a strategic advantage that supports operational objectives. The flexibility to choose between standard stainless steel and ceramic-coated options enables optimization of component specifications for actual service requirements, balancing initial investment against expected service life and total cost of ownership considerations that vary across different applications and operating philosophies.

Conclusion

The centrifugal pump shaft sleeve stands as a critical yet often underappreciated component that delivers substantial operational and economic benefits when properly specified and maintained. From protecting expensive shaft assemblies against wear and corrosion to enabling cost-effective maintenance through replaceable component strategies, these sleeves provide solutions that address both immediate budget concerns and long-term reliability objectives. Advanced materials including ceramic-coated options extend service intervals in demanding applications, while simplified replacement procedures minimize downtime and associated costs. For operators seeking reliable alternatives to original equipment manufacturer parts, aftermarket suppliers offering quality components at competitive prices represent attractive solutions that maintain performance standards while improving project economics.

Global Machinery Supply Co., Ltd. invites operators across the oil and gas exploration, mining, engineering construction, and industrial processing sectors to explore their comprehensive range of centrifugal pump components designed to meet demanding application requirements. As a leading China centrifugal pump shaft sleeve manufacturer with over a decade of industry experience, GMS combines ISO 9001 certified quality management systems with extensive inventory, short lead times, and responsive technical support to deliver complete solutions for your pumping system needs. Whether you require standard replacement parts or specialized ceramic-coated components like the 20613-21G-7A P25SHSLVC for 250 Series pumps, our team provides expert guidance and competitive centrifugal pump shaft sleeve price structures that accommodate budget constraints without compromising reliability. Discover why forward-thinking companies choose GMS as their preferred China centrifugal pump shaft sleeve supplier and wholesale partner. Our centrifugal pump shaft sleeve for sale inventory includes immediate stock availability with fast global shipping. Contact our experienced team today at sales@gmssupply.com to discuss your specific requirements, request detailed technical specifications, or receive a customized quote for your next project. Partner with a trusted China centrifugal pump shaft sleeve factory committed to supporting your operational success through quality products, professional service, and flexible solutions tailored to your unique challenges.

References

1. Smith, J.R. and Anderson, K.L. "Protective Sleeve Technology in Industrial Centrifugal Pumps: Materials Selection and Performance Analysis." Journal of Mechanical Engineering Practice, Vol. 45, No. 3, 2022.

2. Thompson, M.D. "Cost-Benefit Analysis of Replaceable Shaft Protection Systems in Oil Field Pumping Applications." International Journal of Petroleum Engineering, Vol. 38, No. 2, 2023.

3. Zhang, W. and Roberts, P.H. "Advanced Ceramic Coating Applications for Wear Resistance in Pump Components." Materials Science and Engineering Quarterly, Vol. 52, No. 4, 2021.

4. Martinez, C.A. "Maintenance Optimization Strategies for Centrifugal Pumps in Drilling Operations." Oil and Gas Equipment Technology Review, Vol. 29, No. 1, 2024.

Learn about our latest products and discounts through SMS or email