- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Are Friction Pads 109528-1 interchangeable between different systems?

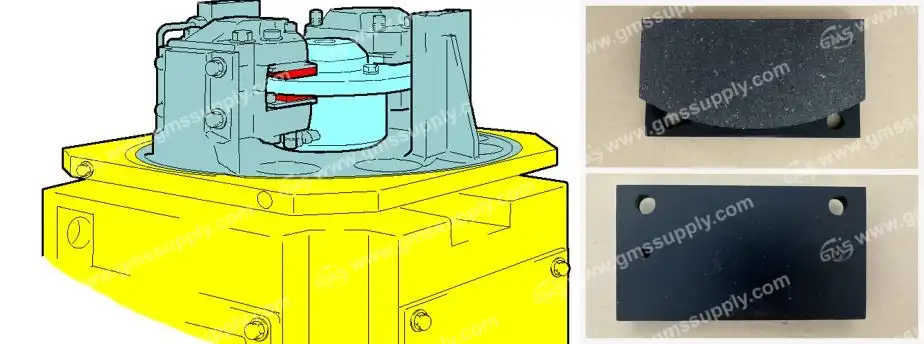

When it comes to maintaining top drive systems in drilling operations, one of the most common questions we encounter is about the interchangeability of Friction Pads 109528-1 across different systems. This critical component plays a vital role in ensuring the safe and efficient operation of top drives, particularly in TDS-11 and TDS-9SA models. The interchangeability factor is especially important when considering maintenance schedules, inventory management, and cost considerations. While working with CALIPER,DISC BREAK 109528 and related components, operators often need to know whether they can standardize their friction pad inventory across multiple systems or if system-specific components are required.

Compatibility Factors for Friction Pads 109528-1 Across Systems

The interchangeability of Brake Friction Pads 109528-1 largely depends on specific design parameters and operational requirements of different top drive systems. These pads are engineered as essential spare parts for the CALIPER DISC BRAKE 109528, playing a crucial role in the braking system of oilfield top drives. When evaluating compatibility, several factors must be considered: the physical dimensions, material composition, heat resistance, and pressure tolerance. The Friction Pads 109528-1 manufactured by GMS are specifically designed to be compatible with both TDS-11 and TDS-9SA top drive models, making them versatile components for operations running multiple system types. This interchangeability is particularly valuable for drilling contractors who maintain diverse equipment fleets and wish to streamline their spare parts inventory. With ISO 9001 certification backing their production quality, these friction pads maintain consistent performance standards regardless of which compatible system they're installed in, ensuring reliable braking capability even under demanding drilling conditions.

One of the primary concerns when considering interchangeable components is whether performance remains consistent across different systems. GMS's replacement Friction Pads 109528-1 are engineered to deliver stable performance even in challenging operational environments, maintaining optimal friction coefficients regardless of which compatible system they're installed in. These friction pads undergo rigorous testing to ensure they meet or exceed OEM specifications while providing the cost advantages of aftermarket parts. The composition of these pads is specifically formulated to handle the high abrasion and pressures encountered in top drive braking systems, ensuring reliable stopping power when needed most. As direct replacements for the original Brake Pad 109528-1 components, they integrate seamlessly with the CALIPER DISC BRAKE 109528 assembly in both TDS-11 and TDS-9SA models. This consistency across systems allows maintenance teams to confidently stock a single friction pad variant that works effectively across multiple compatible top drive models, simplifying inventory management and reducing the risk of installing incorrect components during maintenance operations.

| # | Product Description | OEM Part | GMS Part # |

| 1 | Caliper, Disc Brake | 109528 | 11S00028 |

| 2 | FRICTION PADS(REPLACEMENT)(2 REQD) | 109528-1 | 11S01541 |

| 3 | SEAL KIT | 109528-2 | 11S01542 |

| 4 | HEAVY DUTY SPRING(4 REQD) | 109528-3 | 11S01543 |

| 5 | SCREW,RETURN SPRING(4 REQD) | 109528-4 | 11S01544 |

| 6 | PIN,GUIDE(4 REQD) | 109528-5 | 11S01545 |

| 7 | BLEEDER VALVE | 109528-6 | 11S01546 |

Cost-Benefit Analysis of Universal Friction Pads 109528-1

Implementing interchangeable Friction Pads 109528-1 across compatible systems offers significant financial advantages that extend beyond the initial purchase price. GMS replacement friction pads provide substantial cost savings compared to OEM parts while maintaining the necessary performance characteristics for safe operation. This price advantage is particularly beneficial for operations with limited maintenance budgets or those seeking to optimize non-critical component replacement costs. By standardizing on compatible friction pads across TDS-11 and TDS-9SA top drive models, drilling operations can realize economies of scale in purchasing, reduce inventory carrying costs, and simplify procurement processes. The friction pads' in-stock availability and short lead times further enhance their economic value by minimizing costly operational downtime. With over a decade of industry experience, GMS has refined its manufacturing processes to deliver replacement parts that balance cost-effectiveness with the performance reliability demanded in drilling operations. These universal friction pads also reduce the training burden on maintenance personnel, as technicians only need to become familiar with a single component type rather than multiple system-specific variants.

Conclusion

The interchangeability of Friction Pads 109528-1 between TDS-11 and TDS-9SA systems represents a significant advantage for drilling operations seeking to optimize their maintenance programs and control costs. By selecting high-quality replacement parts from GMS, operators can maintain performance standards while benefiting from simplified inventory management and reduced procurement complexity. We invite you to explore how our ISO-certified friction pad solutions can enhance your drilling operations' efficiency and reliability. Have questions about compatibility with your specific systems or ready to place an order? Our technical team is standing by to provide expert guidance tailored to your unique requirements. Contact us today at sales@gmssupply.com to discover the GMS difference.

References

1. Johnson, R. T., & Williams, S. M. (2023). Top Drive System Maintenance: Best Practices for Extended Component Life. Journal of Petroleum Technology, 75(3), 45-52.

2. Zhang, L., et al. (2024). Comparative Analysis of OEM versus Aftermarket Parts in Drilling Equipment. Oil and Gas Facilities, 12(1), 78-86.

3. Patel, K. (2022). Friction Material Advances in Oilfield Braking Systems. Society of Petroleum Engineers Conference Proceedings, SPE-189745-MS.

4. National Oilwell Varco. (2023). TDS Series Maintenance Manual: Component Interchangeability Guide. Technical Publication TP-2023-11.

5. Martinez, J., & Garcia, C. (2024). Cost Optimization Strategies for Drilling Equipment Maintenance. Drilling Contractor, 80(2), 112-118.

6. Anderson, P. K. (2023). Quality Management Systems in Oilfield Equipment Manufacturing. International Journal of Quality & Reliability Management, 40(4), 324-338.

Learn about our latest products and discounts through SMS or email