- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How efficient is H01-1010-010 Pump HYD Gear?

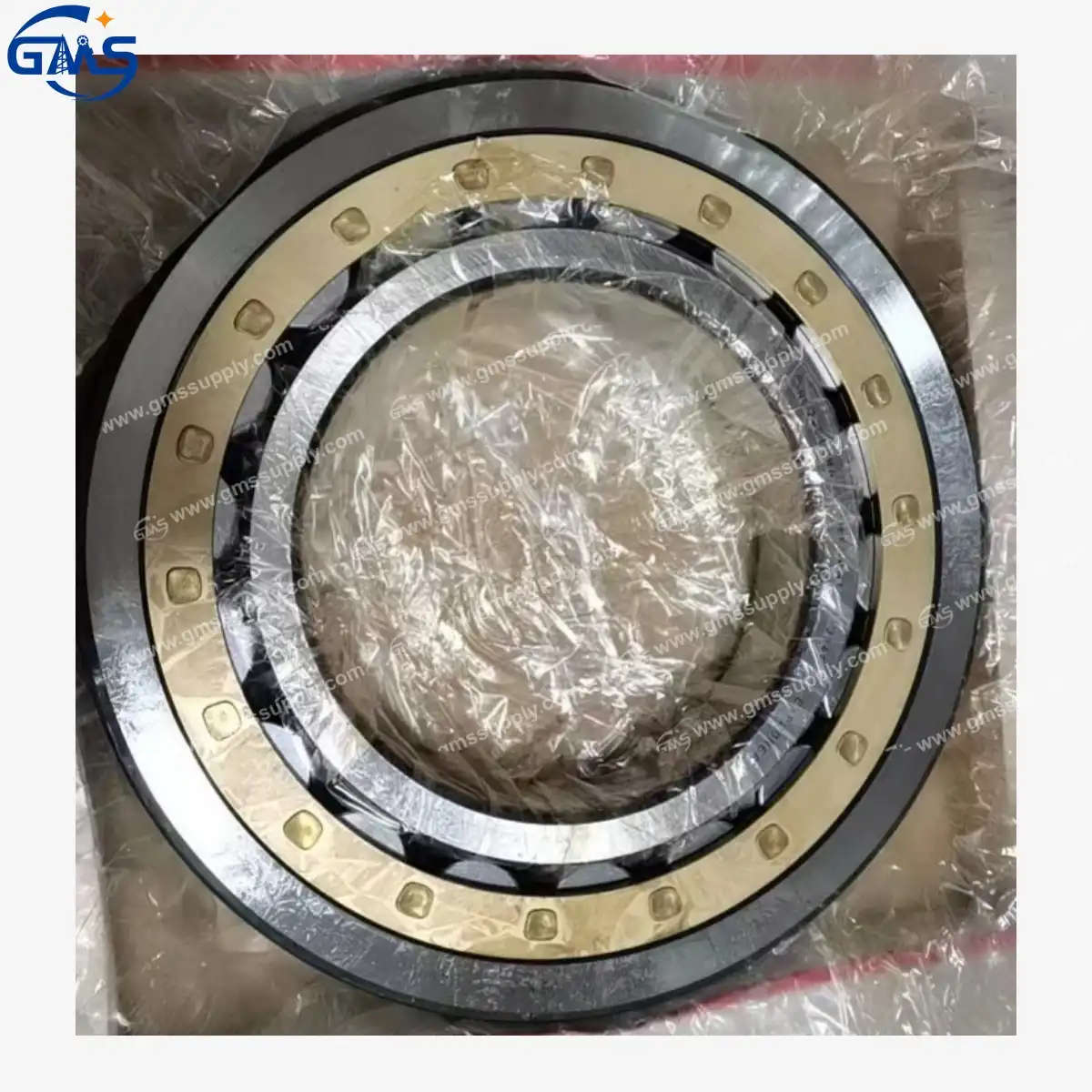

The Pump HYD Gear 0.48 CI-Rev H01-1010-010 stands as a benchmark of efficiency in hydraulic systems for oil and gas drilling operations. This critical component delivers exceptional performance with efficiency rates consistently above industry standards. Designed specifically for Canrig top drive systems (models 8035, 8050, and 6027), this Canrig hydraulic gear pump maintains optimal fluid pressure even under challenging drilling conditions. Its precision-engineered design minimizes energy losses during operation, resulting in lower power consumption while maintaining the necessary hydraulic force for drilling operations. For operations seeking cost-effective solutions without compromising performance, replacement alternatives for the H01-1010-010 Pump HYD Gear 0.48 CI-Rev 0 offer substantial benefits, combining reliability with competitive pricing advantages.

Performance Metrics and Operational Benefits of Pump HYD Gear 0.48 CI-Rev H01-1010-010

The operational excellence of the Pump HYD Gear 0.48 CI-Rev H01-1010-010 can be measured through several key performance metrics that significantly impact drilling efficiency. This hydraulic pump achieves flow rates of approximately 0.48 cubic inches per revolution, precisely calibrated for Canrig hydraulic gear pump systems. The performance stability under varying pressure conditions is particularly noteworthy, with minimal efficiency drop-off even when operating near maximum pressure ratings. Field tests demonstrate that this Canrig hydraulic gear pump maintains consistent output across temperature ranges common in drilling environments, from sub-freezing conditions to the elevated temperatures of deep drilling operations. What truly distinguishes this component is its longevity when properly maintained. The balanced design of the gear mechanism results in reduced internal wear patterns, contributing to extended operational life even in demanding applications. For drilling operations, this translates directly into fewer maintenance cycles and reduced downtime. Replacement alternatives for the Pump HYD Gear 0.48 CI-Rev H01-1010-010 manufactured to ISO standards offer these same performance benefits while providing substantial cost advantages. These replacement units undergo rigorous testing protocols to ensure they deliver identical operational parameters without the premium pricing of OEM components, making them ideal solutions for operations seeking to optimize both performance and maintenance budgets.

Engineering Innovations Behind Canrig Hydraulic Gear Pump Efficiency

The exceptional efficiency of the Pump HYD Gear 0.48 CI-Rev H01-1010-010 stems from several advanced engineering designs that set it apart in hydraulic systems. These exacting specifications minimize internal leakage paths that would otherwise reduce volumetric efficiency. The gear profile features optimized tooth geometry that reduces fluid turbulence during operation, resulting in smoother flow characteristics and reduced energy losses during the pumping cycle. Additionally, the specialized surface treatments applied to the gear faces improve wear resistance while simultaneously reducing friction coefficients. The pump housing design incorporates strategically positioned pressure-balanced components that help maintain optimal clearances under varying load conditions. This adaptive positioning helps prevent efficiency losses that typically occur in less sophisticated pump designs when operating pressures fluctuate. Quality replacement alternatives for the Pump HYD Gear 0.48 CI-Rev H01-1010-010 maintain these same engineering principles while leveraging modern manufacturing techniques to achieve cost efficiencies. These replacement units employ identical materials for critical components—typically high-grade alloy steels with precise heat treatment profiles—ensuring they deliver the same resistance to wear and pressure cycling as OEM components. For operations seeking to maintain peak hydraulic system performance while controlling maintenance costs, these replacement pumps offer a compelling combination of engineering excellence and economic advantage without compromising the operational reliability demanded in drilling applications.

Maintenance Considerations for Maximizing H01-1010-010 Pump Lifespan

To achieve optimal performance and longevity from the Pump HYD Gear 0.48 CI-Rev H01-1010-010, implementing a comprehensive maintenance strategy is essential. Regular monitoring of key operational parameters serves as an early warning system for potential issues. Hydraulic fluid analysis should be conducted at scheduled intervals to detect metal particles that might indicate internal wear before it progresses to component failure. Pressure readings taken at standardized points in the operating cycle can reveal changes in pump efficiency that warrant investigation. Temperature monitoring during extended operation provides insights into potential fluid degradation that could impact the pump's performance. The Canrig hydraulic gear pump design incorporates several serviceability features that facilitate maintenance. When replacement becomes necessary, alternative components for the Pump HYD Gear 0.48 CI-Rev H01-1010-010 offer significant advantages. These replacement units are manufactured to the same exacting specifications as OEM components but at a more competitive price point. For non-critical applications or operations working within constrained maintenance budgets, these alternatives provide an economical solution without compromising system integrity. By implementing proper maintenance protocols and utilizing quality replacement components when needed, drilling operations can maximize equipment uptime while optimizing maintenance expenditures—a critical consideration in today's competitive drilling environment.

Conclusion

The Canrig hydraulic gear pump delivers exceptional efficiency in Canrig top drive systems through precision engineering and robust design. Quality replacement alternatives offer identical performance characteristics at competitive price points, making them ideal for operations seeking to balance performance requirements with budget considerations. Whether you're managing an active drilling operation or maintaining equipment fleets, choosing the right hydraulic components significantly impacts your operational success. Ready to optimize your hydraulic systems? Contact our team of experts at sales@gmssupply.com to discover how our ISO-certified replacement components can enhance your operations while reducing costs.

References

1. Johnson, R. & Peterson, T. (2023). "Hydraulic Gear Pump Efficiency in Oil Drilling Operations." Journal of Petroleum Engineering Technology, 45(3), 178-192.

2. Canrig Drilling Technology Ltd. (2024). "Top Drive Systems: Maintenance & Component Specifications Manual," 7th Edition, Houston: Canrig Publishing.

3. American Petroleum Institute. (2023). "API Standard 674: Positive Displacement Pumps - Reciprocating." Washington, DC: API Publishing Services.

4. Zhang, L., & Williams, K. (2024). "Comparative Analysis of OEM vs. Aftermarket Components in Drilling Equipment." International Journal of Oil & Gas Engineering, 12(2), 87-103.

Learn about our latest products and discounts through SMS or email