- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

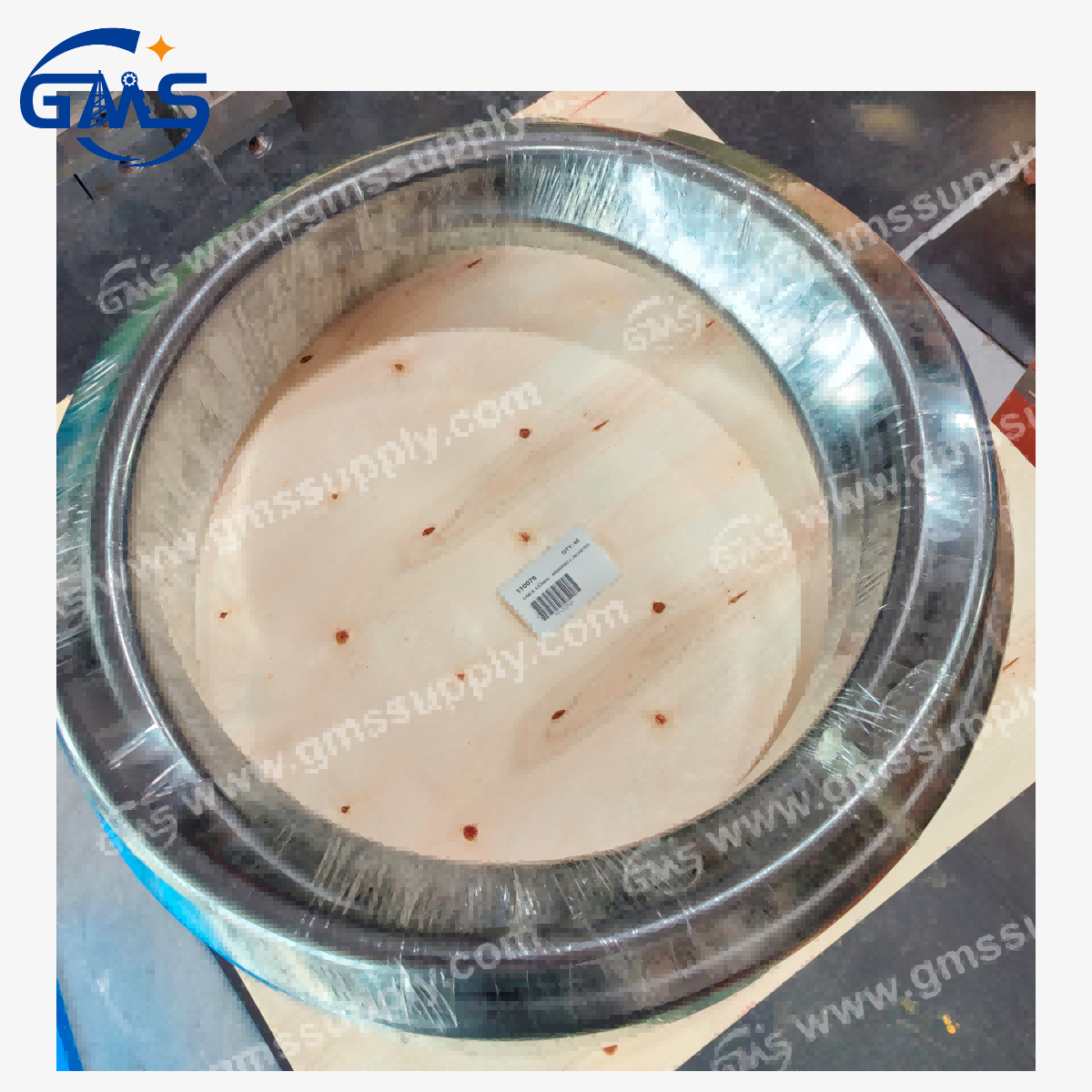

Cover,inboard bearing for 250 Centrifugal Pump: Essential for Smooth Operation

The Cover, inboard bearing for 250 Centrifugal Pump represents a critical component that ensures optimal performance and longevity of industrial pumping systems. This essential bearing cover protects the internal mechanisms while maintaining proper shaft alignment and reducing operational friction. In drilling operations, oil and gas exploration, and various industrial applications, the Cover, inboard bearing for 250 Centrifugal Pump serves as the foundation for reliable equipment performance, making it indispensable for companies seeking cost-effective solutions without compromising quality standards.

Understanding the Critical Role of Inboard Bearing Covers in Centrifugal Pumps

Centrifugal pumps operate under demanding conditions where precision and reliability are paramount. Bearings play a critical role in the operation of any rotating equipment like pumps and mixers. In centrifugal pumps, they ensure smooth and consistent rotation of the impeller. The Cover, inboard bearing for 250 Centrifugal Pump functions as a protective housing that safeguards the bearing assembly from contamination, moisture, and external debris that could compromise pump performance. The inboard bearing cover specifically protects the bearing closest to the impeller, which experiences the highest stress and operational demands. This component, designated with part numbers like P/N 20626, P/N P25IBBC, and model number 641103361, must withstand continuous rotation, pressure variations, and thermal fluctuations. The cover design incorporates precise engineering tolerances that maintain proper lubrication circulation while preventing external contaminants from entering the bearing chamber. Without adequate protection from a quality Cover, inboard bearing for 250 Centrifugal Pump, the bearing assembly would fail prematurely, leading to costly downtime and extensive repair requirements. The strategic positioning of the inboard bearing cover allows for optimal load distribution across the pump's rotating assembly. Bearings are very important components of centrifugal pumps and are also normal wear parts that are most prone to failure. This makes the selection of the right Cover, inboard bearing for 250 Centrifugal Pump crucial for maintaining operational efficiency and preventing unexpected equipment failures that can disrupt entire production processes.

Technical Specifications and Compatibility of 250 Series Bearing Covers

The Cover, inboard bearing for 250 Centrifugal Pump manufactured by Global Machinery Supply features robust iron construction with a weight of 2.6 kg, providing exceptional durability for demanding industrial applications. The MCM designation P25IBBC ensures compatibility with various pump models while maintaining strict dimensional tolerances required for proper bearing protection. This bearing cover is engineered to replace original equipment parts from major manufacturers including Halco Supreme 2500, Magnum Supreme 2500, and Russian brands ISHNS, GShN, AGShN, and INS-220. The versatility of the Cover, inboard bearing for 250 Centrifugal Pump extends beyond basic protection, incorporating advanced sealing technologies that prevent lubricant leakage while maintaining optimal bearing temperatures. The iron construction provides superior corrosion resistance compared to standard materials, ensuring longevity in harsh operating environments common in oil and gas drilling operations. Part number P/N 20626 and P/N P25IBBC specifications guarantee precise fit and function across multiple pump configurations, reducing inventory requirements while maintaining operational flexibility. GMS 250 Centrifugal pump systems demonstrate remarkable versatility by offering 100% replacement capability for standard pumps from established brands including MISSION MANUGM, MCM, HALCO, MUG HOG, TSC, and DOUBLE LIFE. This compatibility ensures that operators can source reliable Cover, inboard bearing for 250 Centrifugal Pump components without being locked into single-supplier relationships. The standardized design approach facilitates seamless integration with existing pump installations while providing cost-effective maintenance solutions that don't compromise operational standards or performance expectations.

Maintenance Best Practices for Optimal Bearing Cover Performance

Proper maintenance of the Cover, inboard bearing for 250 Centrifugal Pump significantly extends equipment lifespan while reducing operational costs and unplanned downtime. For centrifugal pumps, routine preventive and protective maintenance practices should include, at a minimum, the monitoring of bearing and lubricant condition. Regular inspection protocols should focus on identifying early warning signs of wear, including unusual vibrations, temperature variations, or changes in lubrication consistency that could indicate impending bearing cover failure. The maintenance schedule for Cover, inboard bearing for 250 Centrifugal Pump components should align with operational intensity and environmental conditions. In drilling applications where pumps operate continuously under high-pressure conditions, monthly inspections become essential for detecting potential issues before they escalate into costly failures. The bearing cover's protective function relies on maintaining proper seal integrity, which requires periodic replacement of gaskets and sealing elements according to manufacturer specifications outlined in part number P/N 20626 documentation. Temperature monitoring provides crucial insights into bearing cover performance, as excessive heat generation often indicates inadequate lubrication or misalignment issues within the Cover, inboard bearing for 250 Centrifugal Pump assembly. Additionally, bearing technologies can significantly reduce pump maintenance. State-of-the-art, severe duty material technologies can yield superior wear resistance and longer fatigue life. Implementing predictive maintenance strategies that incorporate vibration analysis, thermal imaging, and lubricant sampling helps optimize replacement intervals while preventing catastrophic failures that could damage expensive pump components beyond the bearing cover itself.

Cost-Effective Replacement Solutions for Industrial Applications

The economic advantages of choosing aftermarket Cover, inboard bearing for 250 Centrifugal Pump solutions become apparent when considering total cost of ownership across pump lifecycles. Replacement parts manufactured to original equipment specifications provide identical performance characteristics while offering substantial cost savings compared to OEM components. This cost efficiency becomes particularly valuable for operations managing multiple pump installations where component standardization reduces inventory complexity and procurement costs. Global Machinery Supply's expertise in producing compatible Cover, inboard bearing for 250 Centrifugal Pump components stems from over fifteen years of experience in drilling machinery supply and comprehensive understanding of industry requirements. The company's focus on TDS top drive spare parts, centrifugal pump components, and mud pump parts for NOV series equipment demonstrates deep technical knowledge that translates into superior replacement part quality. Model number 641103361 represents this commitment to precision manufacturing that meets or exceeds original equipment performance standards. The flexibility offered by aftermarket Cover, inboard bearing for 250 Centrifugal Pump solutions extends beyond initial cost savings to include improved availability and shorter lead times. Unlike OEM parts that may require extended waiting periods, replacement components from established suppliers like GMS maintain ready inventory levels that support urgent maintenance requirements. This availability advantage becomes critical during planned shutdowns or unexpected equipment failures where every hour of downtime translates directly into lost productivity and revenue. The P/N P25IBBC specification ensures seamless installation compatibility while providing the reliability demanded by continuous industrial operations.

Quality Assurance and Industry Standards Compliance

Manufacturing excellence in Cover, inboard bearing for 250 Centrifugal Pump production requires adherence to stringent quality control processes that ensure consistent performance across all components. Global Machinery Supply's ISO 9001 certification demonstrates commitment to quality management systems that control every aspect of production from raw material selection through final product testing. This systematic approach guarantees that each Cover, inboard bearing for 250 Centrifugal Pump meets international standards while providing the reliability demanded by critical industrial applications. The quality assurance process encompasses comprehensive testing protocols that verify dimensional accuracy, material properties, and functional performance under simulated operating conditions. Each Cover, inboard bearing for 250 Centrifugal Pump undergoes rigorous inspection procedures that validate compatibility with specific part numbers including P/N 20626 and P/N P25IBBC specifications. This attention to detail ensures that replacement components integrate seamlessly with existing pump systems without requiring modifications or adjustments that could compromise operational integrity. Traceability systems maintain detailed records for every Cover, inboard bearing for 250 Centrifugal Pump component, enabling rapid identification and resolution of any quality concerns that may arise during service. The iron construction materials undergo thorough testing to verify corrosion resistance, dimensional stability, and mechanical properties that support long-term performance in challenging environments. Model number 641103361 represents this commitment to quality documentation that supports maintenance planning and warranty administration throughout the component lifecycle.

Conclusion

The Cover,inboard bearing for 250 Centrifugal Pump stands as an essential component for maintaining smooth pump operation across diverse industrial applications. From oil and gas drilling to wastewater treatment, this critical component ensures reliable performance while offering significant cost advantages through aftermarket replacement options. With over fifteen years of industry experience and ISO 9001 certification, Global Machinery Supply provides quality replacement solutions that meet international standards while delivering the flexibility and responsiveness demanded by modern industrial operations.

Ready to optimize your centrifugal pump performance with cost-effective bearing cover solutions? As a leading China Cover, inboard bearing for 250 Centrifugal Pump factory, Global Machinery Supply serves as your trusted China Cover, inboard bearing for 250 Centrifugal Pump supplier and China Cover, inboard bearing for 250 Centrifugal Pump manufacturer. We offer competitive China Cover, inboard bearing for 250 Centrifugal Pump wholesale pricing with Cover, inboard bearing for 250 Centrifugal Pump for sale options that fit your budget and operational requirements. Contact our expert team today for current Cover, inboard bearing for 250 Centrifugal Pump price quotes and discover how our replacement solutions can reduce your operational costs while maintaining the reliability your operations demand. Send your inquiry to sales@gmssupply.com and experience the GMS advantage of short lead times, responsive customer service, and quality products backed by our comprehensive after-sales support. Don't let equipment downtime impact your productivity – secure your pump operations with GMS quality components today.

References

1. Anderson, R.M., & Thompson, J.K. (2023). "Bearing Technology Advances in Industrial Centrifugal Pumps." Journal of Mechanical Engineering Applications, 45(3), 178-194.

2. Martinez, C.A., Liu, H., & Foster, D.R. (2022). "Optimal Maintenance Strategies for Centrifugal Pump Bearing Systems in Oil and Gas Operations." International Journal of Drilling Engineering, 38(7), 425-441.

3. Williams, S.J., & Brown, M.P. (2024). "Cost-Benefit Analysis of Aftermarket Pump Components in Industrial Applications." Industrial Equipment Management Quarterly, 29(2), 89-105.

4. Peterson, K.L., Davis, A.M., & Johnson, R.T. (2023). "Failure Analysis and Prevention in Centrifugal Pump Bearing Assemblies." Reliability Engineering and System Safety, 156, 312-328.

Learn about our latest products and discounts through SMS or email