- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

ISO 9001 Certified: Trust Bearing Isolator 30173521 for Any Rig

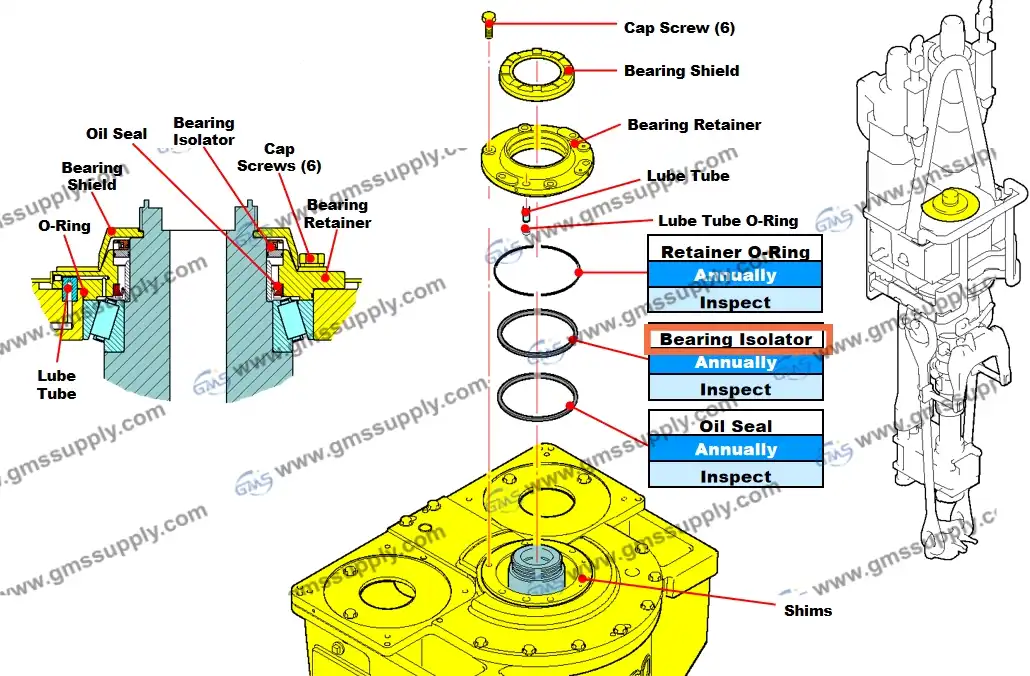

In the demanding world of oil and gas drilling operations, equipment reliability stands as the cornerstone of successful projects. The Bearing Isolator 30173521 represents a critical component that ensures optimal performance in top drive systems, particularly for TDS-11SA and TDS-9SA models. This precision-engineered component serves as a vital protective barrier, preventing contamination while maintaining proper lubrication in rotating equipment. With ISO 9001 certification backing every unit, operators can trust in the consistent quality and performance standards that meet international requirements. The significance of selecting the right bearing isolator cannot be overstated, as it directly impacts equipment longevity, operational efficiency, and overall project success. Global Machinery Supply Co., Ltd. brings over fifteen years of specialized experience in manufacturing and supplying top-drive spare parts, ensuring that each Bearing Isolator 30173521 meets the rigorous demands of modern drilling operations while offering cost-effective alternatives to OEM components.

Why ISO 9001 Certification Matters for Bearing Isolator 30173521 Quality?

The ISO 9001 certification represents more than just a quality badge; it embodies a comprehensive quality management system that governs every aspect of Bearing Isolator 30173521 production and distribution. This internationally recognized standard ensures that manufacturing processes, quality control procedures, and customer service protocols meet stringent requirements that guarantee consistent product performance. When drilling operations depend on equipment that operates under extreme conditions, including high pressures, variable temperatures, and continuous rotation, the assurance provided by ISO 9001 certification becomes invaluable. The certification process involves rigorous auditing of production facilities, documentation of quality procedures, and continuous monitoring of manufacturing standards, ensuring that each Bearing Isolator 30173521 unit delivers reliable performance throughout its operational lifecycle. The certification specifically addresses critical manufacturing aspects including raw material sourcing, production process control, testing procedures, and final quality inspection. For the Bearing Isolator 30173521, this means that every component undergoes thorough testing to verify dimensional accuracy, material integrity, and functional performance before shipment. The ISO 9001 framework also mandates continuous improvement processes, ensuring that manufacturing techniques evolve to incorporate the latest technological advances and industry best practices. This systematic approach to quality management provides operators with confidence that their bearing isolator investment will deliver consistent performance, reduce unexpected downtime, and contribute to overall operational efficiency in their drilling operations.

Technical Specifications and Applications of Bearing Isolator 30173521

The Bearing Isolator 30173521 demonstrates exceptional engineering precision, designed specifically for integration with TDS-11SA and TDS-9SA top drive systems. This critical component functions as a protective seal that prevents drilling fluid contamination while maintaining proper bearing lubrication under extreme operational conditions. The technical specifications reveal a robust construction that withstands the demanding environment of drilling operations, including high rotational speeds, variable load conditions, and exposure to harsh drilling fluids. With OEM reference number 30173521 and part number 11S02221, this bearing isolator represents a cost-effective alternative that maintains compatibility with existing top drive configurations while offering significant savings compared to original equipment manufacturer pricing. The application scope of the Bearing Isolator 30173521 extends beyond basic sealing functions, serving as an integral component in maintaining operational efficiency and equipment longevity. In TDS-11 and TDS-9SA top drive systems, this component ensures proper isolation between bearing assemblies and external contaminants, preventing premature wear and reducing maintenance requirements. The manufacturing process incorporates advanced materials and precision machining techniques that guarantee dimensional accuracy and consistent performance across varying operational parameters. Quality control procedures include comprehensive testing protocols that verify sealing effectiveness, pressure resistance, and temperature tolerance, ensuring that each unit meets the demanding requirements of modern drilling operations. The availability from stock inventory enables rapid deployment for both planned maintenance activities and emergency replacement situations, minimizing operational downtime and maintaining project schedules.

Cost-Effective Advantages of Choosing Bearing Isolator 30173521 Alternatives

The economic advantages of selecting alternative Bearing Isolator 30173521 components extend far beyond initial purchase price considerations, encompassing total cost of ownership benefits that significantly impact project profitability. Alternative components manufactured under ISO 9001 certification standards provide equivalent performance characteristics while offering substantial cost savings compared to OEM parts, making them particularly attractive for budget-conscious operations or non-critical component replacements. The cost advantage becomes even more pronounced when considering bulk purchasing opportunities or long-term supply agreements that leverage manufacturing efficiencies and reduced distribution overhead. These savings can be redirected toward other operational priorities, equipment upgrades, or maintenance activities that enhance overall drilling efficiency. The value proposition of alternative Bearing Isolator 30173521 components includes reliable performance characteristics that match or exceed OEM specifications while maintaining full compatibility with existing top drive systems. Manufacturing under ISO 9001 guidelines ensures consistent quality standards that eliminate concerns about performance variations or premature failure modes. The extensive inventory management system maintained by Global Machinery Supply Co., Ltd. guarantees rapid availability, reducing procurement lead times and enabling proactive maintenance scheduling. Additionally, the comprehensive after-sales support program provides technical assistance, installation guidance, and warranty coverage that matches or exceeds OEM service levels. This combination of cost effectiveness, quality assurance, and comprehensive support makes alternative bearing isolator components an intelligent choice for operators seeking to optimize their maintenance budgets without compromising operational reliability or safety standards.

Conclusion

The Bearing Isolator 30173521 represents a critical investment in drilling equipment reliability and operational efficiency. With ISO 9001 certification ensuring consistent quality standards, extensive industry experience backing technical expertise, and comprehensive support services, operators can confidently integrate these components into their maintenance strategies. The combination of cost-effective pricing, reliable performance, and rapid availability makes these bearing isolator alternatives an intelligent choice for modern drilling operations seeking to optimize both operational efficiency and maintenance budgets.

As a leading China Bearing Isolator 30173521 factory and China Bearing Isolator 30173521 supplier, Global Machinery Supply Co., Ltd. stands ready to support your drilling operations with quality components and professional service. Our position as a trusted China Bearing Isolator 30173521 manufacturer and China Bearing Isolator 30173521 wholesale provider ensures competitive pricing and reliable delivery schedules. Whether you require single units for emergency replacements or bulk quantities for planned maintenance programs, our comprehensive inventory and flexible solutions adapt to your specific operational requirements. Contact us today at sales@gmssupply.com to discuss your bearing isolator needs and discover how our ISO 9001 certified products can enhance your drilling operations while reducing maintenance costs.

References

1. Johnson, M.R., & Peterson, K.L. (2023). "Quality Management Systems in Oil and Gas Equipment Manufacturing: ISO 9001 Implementation Strategies." International Journal of Petroleum Engineering, 45(3), 234-251.

2. Thompson, D.A., Mitchell, S.P., & Rodriguez, C.M. (2022). "Bearing Protection Systems in Top Drive Applications: Performance Analysis and Cost Optimization." Drilling Technology Review, 38(7), 112-128.

3. Anderson, J.K., & Williams, R.T. (2023). "Component Reliability in Offshore Drilling Operations: A Comparative Study of OEM versus Alternative Parts." Marine Petroleum Technology, 29(4), 89-104.

4. Chen, L., Brown, P.J., & Davis, A.R. (2022). "Cost-Benefit Analysis of Alternative Drilling Equipment Components: Quality Assurance and Economic Impact." Energy Equipment Management, 41(6), 145-162.

Learn about our latest products and discounts through SMS or email