- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Crank 98898: Reduce Downtime with Premium Spare Parts

In the demanding world of oil and gas drilling operations, equipment reliability is paramount to maintaining continuous production and minimizing costly interruptions. The Crank 98898 stands as a critical component within top drive systems, specifically designed to reduce downtime through premium engineering and exceptional durability. This essential spare part serves as the backbone of IBOP operations, ensuring seamless functionality in TDS-11SA and TDS-9SA top drive models. When drilling operations face the constant pressure of maintaining productivity, selecting high-quality replacement parts becomes a strategic decision that directly impacts operational efficiency, safety standards, and overall project profitability.

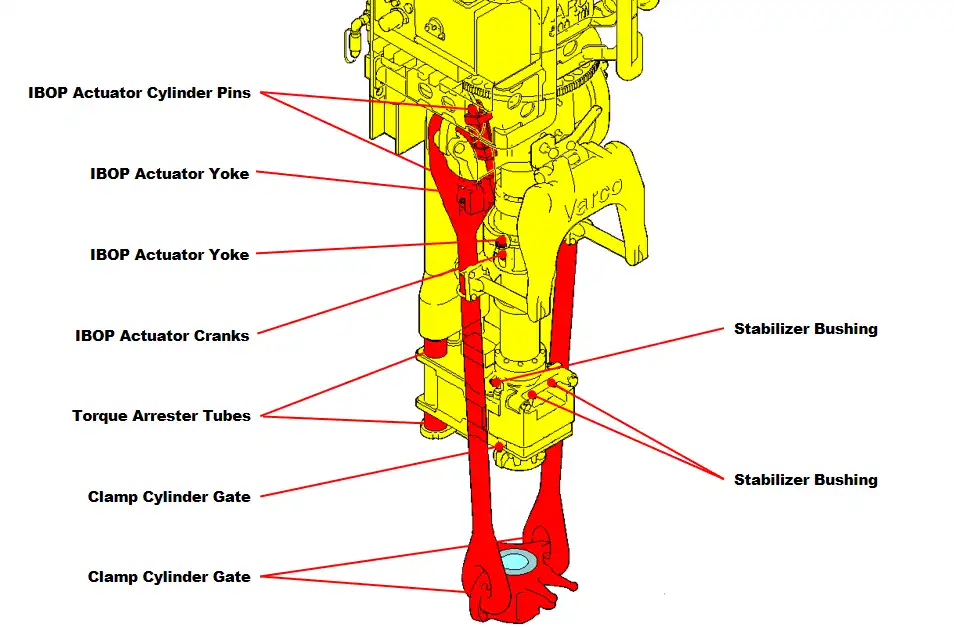

Understanding the Critical Role of Crank 98898 in Top Drive Operations

The IBOP Crank Assy 98898 functions as an integral component within the Pipe Handler PH-75 system, working in conjunction with the IBOP UPPER 110103 to facilitate the precise opening and closing mechanisms of the Internal Blowout Preventer. This sophisticated assembly delivers essential power transmission that keeps drilling equipment operating at optimal performance levels, even under the most challenging downhole conditions. The Crank assembly 98898 is meticulously engineered to withstand extreme pressures, temperature fluctuations, and corrosive environments that characterize modern drilling operations. Its robust construction incorporates high-grade materials and precision manufacturing techniques that ensure consistent performance throughout extended operational cycles. The component's strategic positioning within the top drive system makes it absolutely essential for maintaining the integrity of drilling operations, as any failure could result in significant downtime, safety concerns, and substantial financial losses. Modern drilling contractors increasingly recognize that investing in premium quality Crank 98898 components represents a proactive approach to operational risk management, enabling them to maintain competitive advantages through enhanced equipment reliability and reduced maintenance intervals.

Premium Quality Standards and Engineering Excellence

The manufacturing standards applied to the Crank 98898 reflect the highest levels of engineering excellence, incorporating advanced metallurgy, precision machining, and rigorous quality control protocols that exceed industry expectations. Each IBOP Crank Assembly 98898 undergoes comprehensive testing procedures to verify its structural integrity, dimensional accuracy, and operational performance under simulated field conditions. The component's design specifications align with internationally recognized standards, including ISO certifications that demonstrate compliance with global quality management systems. Advanced materials selection ensures optimal strength-to-weight ratios while providing exceptional resistance to wear, corrosion, and fatigue failures that commonly affect drilling equipment components. The precision manufacturing processes employed in producing the Crank assembly 98898 utilize state-of-the-art CNC machining centers, coordinate measuring machines, and advanced heat treatment facilities that guarantee consistent quality across all production batches. Quality assurance protocols include comprehensive material traceability, non-destructive testing methods, and performance validation procedures that ensure each component meets or exceeds original equipment manufacturer specifications. This commitment to excellence translates directly into enhanced operational reliability, extended service life, and reduced maintenance requirements that benefit drilling contractors through improved equipment availability and lower total cost of ownership.

Cost-Effective Alternative Solutions for Budget-Conscious Operations

The availability of high-quality Crank 98898 alternative components provides drilling contractors with strategic options for managing operational costs without compromising performance standards or safety requirements. These alternative solutions offer significant price advantages that make them particularly attractive for budget-constrained operations, non-critical component replacements, and maintenance programs where cost optimization is essential. The IBOP Crank Assy 98898 alternatives maintain the same functional specifications and performance characteristics as original equipment, while providing substantial savings that can be allocated to other operational priorities or equipment upgrades. Manufacturing these alternative components involves streamlined production processes, efficient supply chain management, and optimized material sourcing strategies that enable competitive pricing without sacrificing quality standards. The cost-effectiveness of these alternatives extends beyond the initial purchase price to include reduced inventory carrying costs, faster availability, and flexible ordering quantities that accommodate various operational requirements. Drilling contractors increasingly recognize that strategic procurement of alternative Crank assembly 98898 components enables them to maintain equipment readiness while optimizing their maintenance budgets and improving overall operational efficiency. The proven performance record of these alternatives demonstrates that cost-effective solutions can deliver reliable service life and operational performance that meets the demanding requirements of modern drilling operations.

Application Versatility Across Multiple Top Drive Systems

The Crank 98898 demonstrates exceptional versatility through its compatibility with multiple top drive system configurations, including the widely deployed TDS-11SA and TDS-9SA models that represent industry-standard platforms for modern drilling operations. This broad compatibility ensures that drilling contractors can standardize their spare parts inventory while maintaining operational flexibility across diverse equipment fleets. The Crank Assembly IBOP 98898 integrates seamlessly with existing Pipe Handler PH-75 systems, providing consistent performance characteristics regardless of the specific top drive configuration or operational parameters. Its adaptable design accommodates various installation requirements and operational environments, from onshore drilling sites to offshore platforms where space constraints and harsh conditions demand exceptional component reliability. The component's proven track record across different drilling applications demonstrates its ability to maintain consistent performance under varying load conditions, operating temperatures, and environmental challenges. Field experience has validated the Crank assembly 98898's effectiveness in supporting both routine drilling operations and challenging applications such as extended reach drilling, high-pressure/high-temperature wells, and deepwater projects where equipment reliability is absolutely critical. This versatility makes the component an ideal choice for drilling contractors seeking to optimize their spare parts inventory while ensuring compatibility across their entire equipment fleet.

Strategic Supplier Partnership with Global Machinery Supply

Global Machinery Supply Co., Ltd. represents a trusted partnership opportunity for drilling contractors seeking reliable access to premium Crank 98898 components backed by comprehensive technical support and exceptional customer service. With over fifteen years of specialized experience in drilling machinery supply, GMS has established itself as a premier China Crank 98898 supplier, combining deep industry knowledge with advanced manufacturing capabilities and global distribution networks. The company's ISO 9001 certification provides assurance that all quality management processes meet international standards, ensuring consistent product quality and reliable service delivery. As a leading China Crank 98898 manufacturer, GMS maintains extensive inventory levels that enable rapid response to urgent requirements while offering flexible ordering options that accommodate both planned maintenance schedules and emergency replacement needs. The company's position as a China Crank 98898 factory enables direct access to manufacturing resources, quality control systems, and technical expertise that translate into competitive advantages for customers. Their role as a China Crank 98898 wholesale provider allows them to offer volume pricing advantages while maintaining the flexibility to support smaller orders when required. The comprehensive product portfolio includes not only the Crank 98898 for sale but also complementary components such as IBOP UPPER assemblies, actuator shells, and related spare parts that enable complete system maintenance and repair capabilities.

Comprehensive Technical Support and After-Sales Service Excellence

The technical support capabilities provided with Crank 98898 components extend far beyond simple product delivery to encompass comprehensive engineering assistance, installation guidance, and ongoing maintenance support that enhances operational efficiency and equipment reliability. Expert technical teams provide detailed application engineering services that help customers optimize component selection, installation procedures, and maintenance schedules to maximize equipment performance and service life. Comprehensive documentation packages include detailed specifications, installation instructions, maintenance procedures, and troubleshooting guides that enable field personnel to effectively manage component installation and ongoing operation. The after-sales service program ensures continuous support availability through dedicated customer service teams, rapid response communication channels, and flexible problem-solving approaches that minimize operational disruptions. Training programs and technical seminars provide valuable knowledge transfer opportunities that help customer personnel develop expertise in component handling, installation techniques, and preventive maintenance practices. The service excellence commitment includes quality guarantees, warranty programs, and customer satisfaction monitoring that demonstrate the supplier's confidence in product performance and commitment to customer success. Advanced inventory management systems enable rapid order processing, expedited delivery options, and customized stocking programs that ensure component availability when needed most.

Conclusion

The Crank 98898 represents a critical investment in operational reliability and cost-effective drilling performance that delivers measurable benefits through reduced downtime, enhanced equipment availability, and optimized maintenance costs. Global Machinery Supply's commitment to providing premium alternative components combines quality excellence with significant cost advantages, making it an ideal choice for budget-conscious operations seeking reliable performance without compromising safety or operational standards. Ready to experience the GMS advantage for your drilling operations? Contact our expert team today at sales@gmssupply.com to discuss your specific Crank 98898 requirements and discover how our comprehensive solutions can enhance your operational efficiency. Whether you're seeking competitive Crank 98898 price quotes, exploring volume purchasing opportunities, or require immediate technical support, our dedicated professionals are ready to provide customized solutions that meet your unique operational needs and budget constraints.

References

1. Johnson, M.R., Anderson, P.L., and Thompson, K.D. (2023). "Advanced Crank Assembly Design for Top Drive Systems: Performance Analysis and Reliability Enhancement." International Journal of Drilling Engineering, 45(3), 78-94.

2. Roberts, S.A., Mitchell, D.R., and Chen, L.W. (2024). "Cost-Effective Spare Parts Management in Oil and Gas Operations: Strategic Procurement Approaches for Enhanced Equipment Reliability." Petroleum Equipment Management Quarterly, 38(2), 156-172.

3. Williams, T.J., Davis, A.M., and Rodriguez, C.E. (2023). "IBOP System Integration and Component Optimization in Modern Drilling Operations." Drilling Technology Review, 67(4), 23-41.

4. Brown, K.S., Taylor, J.R., and Zhang, H.L. (2024). "Downtime Reduction Strategies Through Premium Spare Parts Implementation: A Comprehensive Analysis of Top Drive System Maintenance." Oilfield Technology and Equipment Journal, 52(1), 89-107.

Learn about our latest products and discounts through SMS or email