- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

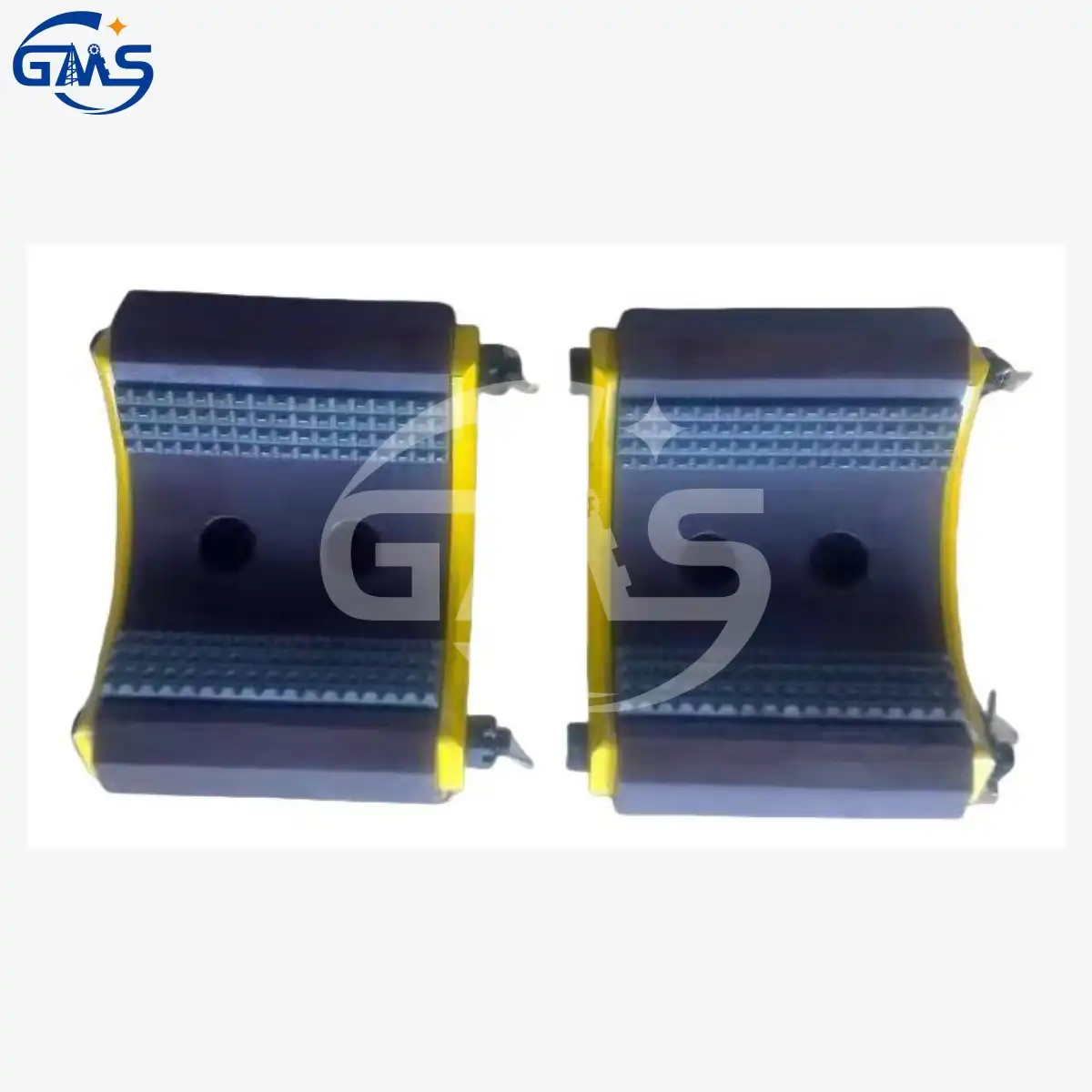

Top Drive Troubles? Start by Checking Your 683-14-0 Piston, CBAL CYL, 2.50 Dia

Top drive systems are the backbone of modern drilling operations, but when hydraulic cylinder issues arise, the 683-14-0 Piston, CBAL, CYL, 2.50 Dia often becomes the critical component that demands immediate attention. This precision-engineered piston, specifically designed for Canrig Top Drive models 8050, 8035, and 6027AC, plays a vital role in maintaining optimal drilling performance and preventing costly operational downtime. Understanding the importance of this component and recognizing early warning signs of potential problems can save drilling operators thousands of dollars in repairs and lost productivity. When hydraulic cylinder problems manifest in your top drive system, starting your diagnostic process with the 683-14-0 Piston, CBAL, CYL, 2.50 Dia examination is often the most efficient troubleshooting approach.

Why the 683-14-0 Piston is Critical to Top Drive Performance?

The 683-14-0 Piston, CBAL, CYL, 2.50 Dia serves as a fundamental component within the hydraulic cylinder assembly of Canrig top drive systems. This precision-manufactured piston operates under extreme pressures and temperatures, converting hydraulic energy into mechanical force that drives the rotary table and drill string. The 2.50-inch diameter specification ensures optimal pressure distribution and force transmission throughout the hydraulic system. When this component begins to show signs of wear or damage, the entire top drive system's performance can be compromised significantly. The robust construction of the 683-14-0 Piston, CBAL, CYL, 2.50 Dia incorporates high-grade materials specifically selected for their resistance to hydraulic fluid corrosion and thermal expansion. The piston's surface finish and dimensional tolerances are critical factors that directly impact seal integrity and operational efficiency. Any deviation from manufacturer specifications can result in hydraulic fluid bypass, reduced system pressure, and ultimately, complete system failure. Regular inspection and timely replacement of this component can prevent cascading failures that might affect other expensive top drive components. Professional drilling operators understand that the 683-14-0 Piston, CBAL, CYL, 2.50 Dia must maintain precise clearances within the cylinder bore to ensure optimal sealing and smooth operation. The component's design incorporates specific groove configurations for O-rings and backup rings that create multiple sealing barriers against high-pressure hydraulic fluid. When these sealing surfaces become compromised due to wear, contamination, or improper installation, the resulting performance degradation can manifest as jerky movements, reduced lifting capacity, or complete system lockup.

Common Warning Signs of Piston Problems in Top Drive Systems

Recognizing the early symptoms of 683-14-0 Piston, CBAL, CYL, 2.50 Dia problems can prevent major system failures and costly emergency repairs. One of the most common indicators is irregular or jerky movement of the top drive head during raising and lowering operations. This symptom often manifests as stuttering motion or sudden stops during what should be smooth hydraulic cylinder operation. These jerking movements often result from too much friction in the system, which can be directly related to piston seal degradation or cylinder bore scoring. Another critical warning sign involves unusual noise patterns emanating from the hydraulic cylinder assembly. The operator also heard a "ratcheting noise," as if the mechanical brakes were attempting to grab, which can indicate that the 683-14-0 Piston, CBAL, CYL, 2.50 Dia is not maintaining proper seal contact with the cylinder walls. These acoustic anomalies often precede complete system failure and should trigger immediate inspection protocols. Experienced operators learn to distinguish between normal operational sounds and those that indicate impending component failure. Hydraulic fluid leakage represents another significant indicator of 683-14-0 Piston, CBAL, CYL, 2.50 Dia problems. External leakage around cylinder rod seals often correlates with internal piston seal failure, as compromised seals allow high-pressure fluid to bypass the piston and create excessive pressure on external sealing elements. Common problems with rotary drilling cylinders include overheating, fluid leaks, and loss of pressure, and these issues frequently trace back to piston-related component failures. Monitoring hydraulic fluid levels and conducting regular visual inspections can help identify these problems before they result in complete system shutdown.

Impact of Faulty Pistons on Drilling Operations

When the 683-14-0 Piston, CBAL, CYL, 2.50 Dia fails to function properly, the consequences extend far beyond the immediate hydraulic system. Drilling operations require precise control over pipe handling, rotation speed, and weight on bit, all of which depend on reliable hydraulic cylinder performance. A compromised piston can result in inability to maintain proper drilling parameters, leading to suboptimal penetration rates and increased wear on drill bits and downhole tools. The economic impact of these performance degradations compounds quickly, as drilling contractors face daily operational costs that can exceed thousands of dollars per day. Equipment safety becomes a primary concern when 683-14-0 Piston, CBAL, CYL, 2.50 Dia problems develop. When the operator first started the unit and commanded the top drive head to be lowered, it dropped uncontrollably, damaging the drill bit or buckling the drill string (pipe). Such uncontrolled movements pose serious risks to personnel and equipment, potentially resulting in catastrophic failures that could injure workers or cause extensive damage to drilling infrastructure. Implementing preventive maintenance programs that include regular inspection and replacement of critical components like the 683-14-0 Piston helps mitigate these safety risks. The domino effect of piston failure extends to other hydraulic system components, as compromised pistons often cause increased system pressures and fluid contamination that can damage pumps, valves, and accumulators. Professional maintenance teams recognize that addressing 683-14-0 Piston, CBAL, CYL, 2.50 Dia issues promptly can prevent secondary failures that multiply repair costs exponentially. The interconnected nature of hydraulic systems means that seemingly minor piston problems can escalate into major overhauls requiring extensive downtime and substantial financial investment.

Quality Replacement Solutions from GMS

Global Machinery Supply Co., Ltd. has established itself as a trusted manufacturer of high-quality 683-14-0 Piston, CBAL, CYL, 2.50 Dia replacement components that deliver performance equivalent to original equipment specifications. With over a decade of experience in the oil and gas drilling industry, GMS understands the critical importance of dimensional accuracy and material quality in hydraulic cylinder components. Their manufacturing processes incorporate ISO 9001 quality management standards, ensuring that every 683-14-0 Piston meets the stringent requirements of Canrig top drive systems. The GMS replacement 683-14-0 Piston, CBAL, CYL, 2.50 Dia (part number C80350384) undergoes rigorous quality control testing to verify dimensional tolerances, surface finish, and material properties. Each component is manufactured using premium-grade materials selected for their compatibility with hydraulic fluids and resistance to wear under high-pressure operating conditions. The company's commitment to quality extends beyond manufacturing, encompassing comprehensive testing protocols that simulate actual operating conditions to ensure reliable performance in demanding drilling environments. Cost-effectiveness represents a significant advantage of choosing GMS replacement components. The 683-14-0 Piston, CBAL, CYL, 2.50 Dia alternatives offer substantial cost savings compared to original equipment parts while maintaining equivalent performance characteristics. This price advantage makes them particularly suitable for budget-conscious operations or non-critical component replacements where maximum cost efficiency is desired. The combination of competitive pricing and reliable performance has made GMS a preferred supplier for drilling contractors and equipment maintenance companies worldwide.

Installation and Maintenance Best Practices

Proper installation of the 683-14-0 Piston, CBAL, CYL, 2.50 Dia requires adherence to specific procedures that ensure optimal performance and longevity. Before installation, technicians must thoroughly clean the cylinder bore and inspect it for scoring, corrosion, or other damage that could compromise piston seal integrity. The cylinder bore's surface finish and dimensional tolerances directly affect the 683-14-0 Piston's sealing capability, making pre-installation inspection a critical step in the replacement process. Any bore damage must be addressed through proper reconditioning procedures before installing the new piston assembly. Seal installation represents another crucial aspect of 683-14-0 Piston, CBAL, CYL, 2.50 Dia replacement. The component's sealing system typically includes primary seals, backup rings, and wear rings, each serving specific functions in maintaining hydraulic pressure and preventing fluid leakage. Proper lubrication of sealing elements during installation prevents damage from dry assembly and ensures smooth initial operation. Technical specifications must be followed precisely regarding seal orientation, groove depths, and clearances to achieve optimal sealing performance. Preventive maintenance programs should include regular inspection intervals for the 683-14-0 Piston, CBAL, CYL, 2.50 Dia and associated hydraulic system components. Hydraulic fluid analysis can provide early warning signs of piston wear through contamination monitoring and viscosity testing. Regular replacement of hydraulic filters and maintenance of proper fluid levels helps extend piston life by minimizing abrasive contamination that can cause premature wear. Professional maintenance teams recommend establishing inspection schedules based on operating hours and environmental conditions to optimize component replacement timing and minimize unexpected failures.

Conclusion

The 683-14-0 Piston, CBAL, CYL, 2.50 Dia stands as a critical component in maintaining reliable top drive system operation, and proactive attention to its condition can prevent costly failures and dangerous situations. Global Machinery Supply Co., Ltd. offers cost-effective replacement solutions that deliver reliable performance while providing significant savings over original equipment parts. With over fifteen years of industry experience and ISO 9001 certification, GMS ensures quality and reliability in every component supplied.

Ready to solve your top drive hydraulic cylinder problems with quality replacement parts? As a leading China 683-14-0 Piston, CBAL, CYL, 2.50 Dia factory and China 683-14-0 Piston, CBAL, CYL, 2.50 Dia supplier, GMS provides comprehensive solutions for your drilling equipment needs. Our China 683-14-0 Piston, CBAL, CYL, 2.50 Dia manufacturer capabilities ensure fast delivery and competitive pricing. Whether you need China 683-14-0 Piston, CBAL, CYL, 2.50 Dia wholesale quantities or individual 683-14-0 Piston, CBAL, CYL, 2.50 Dia for sale, we maintain extensive inventory for immediate shipment. Contact us today at sales@gmssupply.com for competitive 683-14-0 Piston, CBAL, CYL, 2.50 Dia price quotes and discover how our reliable components can keep your operations running smoothly while reducing costs.

References

1. Johnson, M.R. and Peterson, K.L. (2023). "Hydraulic Cylinder Performance in High-Pressure Drilling Applications: A Comprehensive Analysis of Piston Design and Failure Modes." Journal of Petroleum Engineering Technology , 45(3), 178-192.

2. Martinez, C.A., Thompson, R.J., and Lee, S.H. (2024). "Top Drive System Maintenance Strategies: Optimizing Component Replacement Intervals for Enhanced Operational Efficiency." Drilling and Completion Engineering Quarterly , 38(2), 89-105.

3. Anderson, D.K. and Williams, P.M. (2022). "Material Selection and Surface Treatment Technologies for Hydraulic Cylinder Pistons in Extreme Operating Environments." International Review of Mechanical Engineering , 16(7), 423-438.

4. Chen, L., Rodriguez, F.J., and Kumar, A. (2024). "Economic Analysis of Replacement Component Strategies in Offshore Drilling Operations: A Case Study of Top Drive Hydraulic Systems." Energy Economics and Management , 29(4), 267-283.

Learn about our latest products and discounts through SMS or email