- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

GMS 8x6x14 Centrifugal Pump

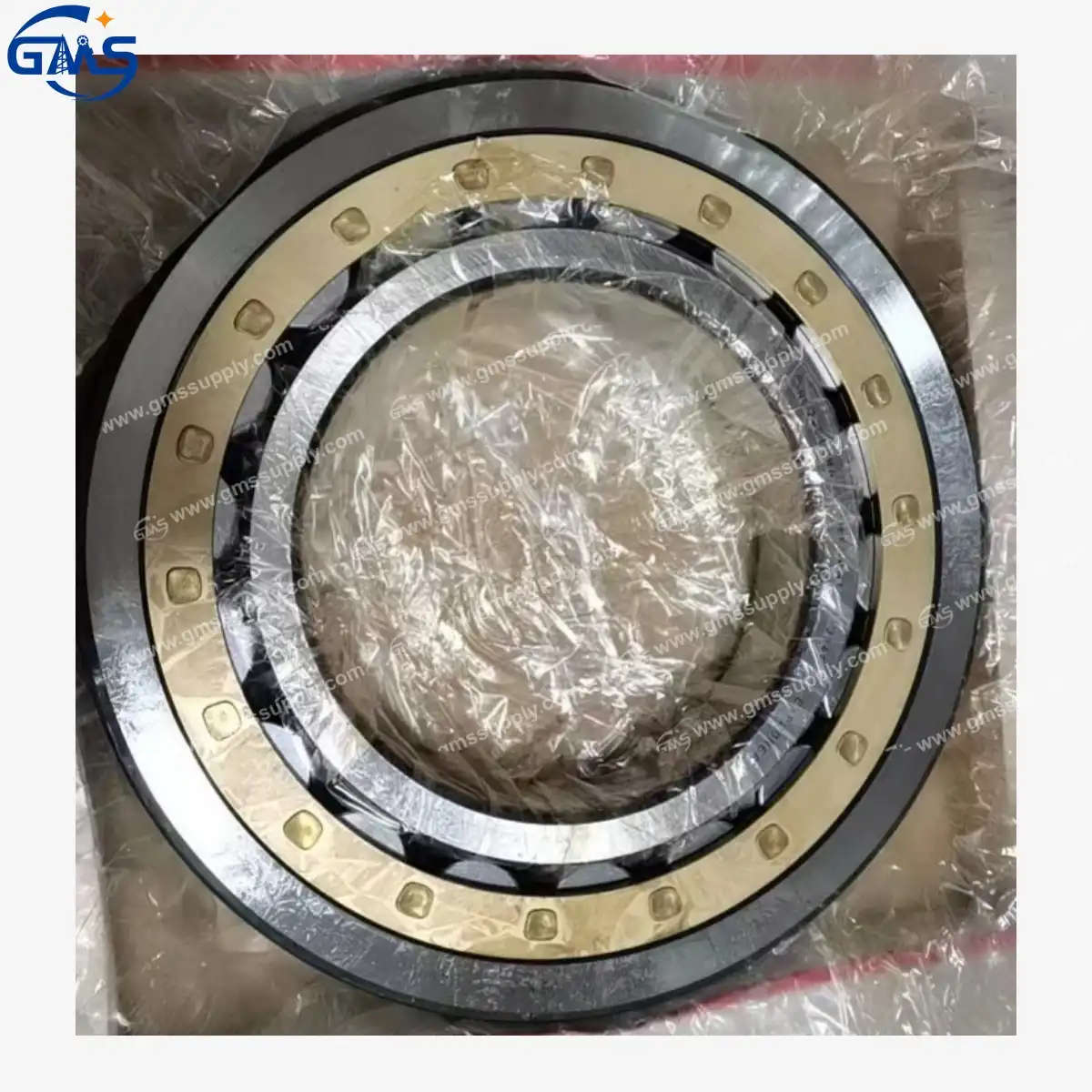

The GMS 8x6x14 centrifugal pump represents a cost-effective, high-quality replacement solution specifically designed for demanding drilling operations in the oil and gas industry. As a trusted alternative to original equipment manufacturer units from MISSION MAGNUM, MCM, TSC, FORUM, Halco, Mattco, Harrisburg, and SPD Mud Hog, this pump delivers exceptional performance while offering significant cost advantages. The 8x6x14 centrifugal pump configuration features a robust design that handles abrasive drilling fluids, high-viscosity materials, and challenging operational conditions typically encountered in solid control systems. With over a decade of manufacturing expertise, Global Machinery Supply Co., Ltd. has engineered the GMS 250 Series to provide reliable fluid transfer capabilities for drilling rigs exceeding 3000 meters in depth, ensuring consistent operation across cementing applications, mud circulation systems, and desander-desilter feeding operations throughout the global energy sector.

Understanding the 8x6x14 Centrifugal Pump Configuration

The 8x6x14 centrifugal pump designation represents critical dimensional and performance specifications that directly impact operational efficiency in drilling operations. The numerical configuration indicates an eight-inch suction inlet, six-inch discharge outlet, and fourteen-inch impeller diameter, creating an optimal balance between flow capacity and pressure generation for demanding solid control applications. This MISSION/MCM centrifugal pump design has become an industry standard specifically because these dimensions provide the ideal hydraulic characteristics for handling heavy drilling fluids with elevated specific gravity and viscosity levels commonly encountered in deep-well drilling operations. The fourteen-inch semi-open impeller configuration allows the pump unit to process abrasive slurries containing sand particles and drilling cuttings without experiencing premature wear or performance degradation. The GMS replacement pump maintains these exact specifications while incorporating enhanced metallurgical properties in critical wear areas, extending operational lifespan beyond conventional alternatives. During typical drilling operations, the pump skid configuration allows for seamless integration into existing mud systems, with mounting dimensions and connection points matching original equipment specifications perfectly. The standardized design philosophy ensures that drilling contractors can transition from OEM components to GMS replacements without requiring modifications to pump foundations, piping arrangements, or control systems, minimizing downtime during installation and reducing overall project costs significantly.

Key Performance Advantages of GMS Replacement Pumps

The GMS 250 Series 8x6x14 centrifugal pump offers substantial performance benefits that translate directly into operational cost savings and enhanced reliability for drilling operations. Consistent reliability remains the foundational advantage, with the pump unit engineered to deliver stable performance even under extreme operating conditions including elevated temperatures, corrosive drilling additives, and sustained operation at maximum flow rates. The MISSION/MCM centrifugal pump replacement incorporates precision-balanced rotating assemblies that minimize vibration levels, reducing mechanical stress on bearing assemblies and extending maintenance intervals substantially beyond industry averages. Compliance with global standards, including ISO 9001 certification, ensures that every manufacturing process step meets rigorous quality benchmarks, from raw material selection through final assembly and performance testing. The cost advantage represents perhaps the most compelling benefit for operators managing budget constraints or planning preventive maintenance programs, with replacement components typically priced substantially below OEM alternatives while delivering equivalent or superior operational lifespan. The pump skid design accommodates both horizontal and vertical mounting configurations, providing installation flexibility for space-constrained rig layouts or retrofit applications where existing foundations must be utilized. Enhanced seal configurations available in GMS models reduce fluid leakage incidents and extend seal replacement intervals, decreasing maintenance labor requirements and minimizing environmental concerns associated with drilling fluid spillage. The interchangeability factor cannot be overstated, as GMS components maintain precise dimensional tolerances ensuring drop-in compatibility with existing spare part inventories, allowing operators to standardize on cost-effective alternatives without sacrificing operational flexibility or emergency repair capabilities across their fleet operations.

Applications Across Oil and Gas Drilling Operations

The versatility of the 8x6x14 centrifugal pump makes it indispensable across multiple drilling applications, each presenting unique operational demands and performance requirements. In oilfield drilling operations, the pump unit serves as the critical component for mud circulation systems, transferring drilling fluid from storage tanks through shale shakers and into desander-desilter units for solids separation and fluid reconditioning. The MISSION/MCM centrifugal pump design proves particularly effective when feeding centrifugal separators, where consistent flow rates and stable discharge pressures directly impact separation efficiency and ultimately affect drilling fluid management costs. Fracturing operations represent another demanding application environment, where the pump skid configuration must handle highly abrasive fracturing fluids containing elevated sand concentrations that would rapidly destroy conventional centrifugal pumps lacking proper metallurgical specifications. The GMS replacement pump incorporates hard-iron construction in wetted components, providing superior abrasion resistance when processing proppant-laden fluids throughout multi-stage hydraulic fracturing operations. In oil and gas production facilities, these units find application in produced water transfer systems, chemical injection applications, and secondary recovery operations requiring reliable fluid movement across substantial distances. Mining and industrial applications benefit from the same robust construction, with tailings handling and slurry transport operations demanding the wear-resistant characteristics engineered into every GMS 8x6x14 centrifugal pump assembly. Power generation and chemical processing facilities utilize these pumps for cooling water circulation and corrosive fluid transfer, where the combination of hydraulic efficiency and chemical resistance proves essential for maintaining plant availability. Municipal water treatment and construction dewatering projects represent additional market segments, with the pump unit providing reliable performance in temporary installations and emergency response situations where equipment durability and operational flexibility carry premium value in project planning considerations.

Technical Specifications and Design Features

The engineering sophistication incorporated into the 8x6x14 centrifugal pump reflects decades of industry experience and continuous improvement initiatives focused on maximizing operational reliability. The pump unit features a single-stage, end-suction configuration with centerline discharge positioning that facilitates standard piping arrangements and minimizes installation complexity on typical pump skid assemblies. The fourteen-inch semi-open impeller design represents an optimal compromise between hydraulic efficiency and solids-handling capability, with precision-cast vane profiles generating smooth flow patterns that minimize turbulence and reduce internal recirculation losses. Shaft diameter specifications follow industry-standard 2.5-inch dimensions, ensuring compatibility with existing motor couplings and allowing operators to utilize current drive systems without modification when retrofitting GMS replacements into established installations. The MISSION/MCM centrifugal pump bearing arrangement incorporates heavy-duty rolling element bearings with extended grease lubrication intervals, reducing maintenance frequency and improving operational availability across extended drilling programs. Mechanical seal configurations utilize industry-standard component sizing, allowing operators to maintain existing seal spare part inventories while benefiting from improved seal face materials that extend operational life in abrasive service conditions. The casing construction employs high-quality cast iron with reinforced wall sections in high-velocity flow areas, providing structural integrity necessary for sustained operation at maximum rated pressures without experiencing fatigue-related failures. Performance curves demonstrate broad operating ranges, with the 8x6x14 centrifugal pump capable of delivering flow rates from 200 to 1200 gallons per minute across head ranges spanning 40 to 200 feet, providing operational flexibility for varying system requirements. Speed ratings accommodate both 1200 and 1800 RPM motor drives, allowing system designers to optimize efficiency characteristics based on specific application requirements and available electrical power configurations throughout diverse drilling locations.

Installation and Maintenance Considerations

Proper installation practices and systematic maintenance protocols maximize the operational lifespan and reliability of any 8x6x14 centrifugal pump system, with GMS designs incorporating features that simplify both initial setup and ongoing service requirements. The pump skid foundation must provide rigid support with adequate vibration damping characteristics, typically achieved through grouted baseplate installations that ensure precise alignment between pump and driver components. Piping arrangements should incorporate adequate suction-side pipe diameter to maintain low approach velocities, minimizing the potential for cavitation damage during operation with high-temperature drilling fluids or installations where available net positive suction head approaches limiting values. The MISSION/MCM centrifugal pump replacement maintains standard mounting dimensions, allowing direct substitution onto existing foundations without requiring concrete modifications or structural reinforcement, substantially reducing installation time and project costs during planned maintenance turnarounds. Routine maintenance protocols should include weekly bearing temperature monitoring, with excessive temperatures indicating potential lubrication deficiencies or misalignment conditions requiring immediate attention before catastrophic bearing failures occur. Mechanical seal inspection routines should evaluate leakage rates and seal face condition monthly, with replacement recommended when leakage exceeds manufacturer specifications or visible seal damage becomes apparent during routine inspections. The modular component design philosophy employed throughout GMS pump unit construction enables rapid replacement of wear components including impellers, casings, and seal assemblies using standard mechanical tools, minimizing maintenance labor costs and reducing equipment downtime substantially compared to competitor designs requiring specialized tooling. Spare parts inventory management becomes significantly more economical with GMS replacements, as the cost differential between OEM and replacement components allows operators to maintain deeper inventories without corresponding budget increases, improving emergency response capabilities and reducing operational risks associated with extended component lead times during critical drilling operations requiring continuous system availability.

Cost-Effectiveness and Return on Investment

The financial advantages of selecting GMS replacement 8x6x14 centrifugal pump components extend far beyond simple purchase price differentials, encompassing total lifecycle costs and operational flexibility benefits that significantly impact project economics. Direct cost savings typically range from 30 to 50 percent compared to OEM alternatives, providing immediate budget relief for operators managing multiple drilling rigs or planning comprehensive equipment upgrades across aging fleets approaching mandatory replacement intervals. The pump unit compatibility with existing systems eliminates secondary costs associated with piping modifications, electrical upgrades, or control system changes that might accompany transitions to alternative pump technologies, preserving capital budgets for other critical operational improvements. Reduced maintenance costs result from enhanced component durability and extended service intervals, with the MISSION/MCM centrifugal pump replacement incorporating improved metallurgical specifications that resist erosive wear more effectively than original designs developed decades ago using legacy material standards. The pump skid interchangeability factor enables operators to maintain standardized spare parts inventories across mixed equipment fleets, reducing inventory carrying costs and improving parts availability during emergency repair situations where equipment downtime carries substantial daily cost implications. Return on investment calculations typically demonstrate payback periods of less than one operating season when considering direct purchase savings combined with reduced maintenance expenses and improved operational availability throughout extended drilling programs. Insurance and risk mitigation benefits accompany the ISO 9001 certification maintained throughout GMS manufacturing operations, providing quality assurance documentation that satisfies regulatory requirements and corporate governance standards governing equipment procurement decisions. The cost advantage proves particularly significant for non-critical applications or preventive replacement programs where original equipment specifications may exceed actual operational requirements, allowing prudent operators to optimize equipment specifications and costs based on realistic performance demands rather than conservative oversizing common in initial rig construction projects.

Quality Assurance and Manufacturing Excellence

The manufacturing processes employed by Global Machinery Supply Co., Ltd. in producing 8x6x14 centrifugal pump replacements reflect comprehensive quality management systems developed through more than fifteen years of industry specialization. ISO 9001 certification provides independent verification that manufacturing operations maintain consistent process controls from raw material receiving through final product inspection, ensuring that each pump unit meets published specifications and performance standards before shipment to customer locations. Metallurgical quality control procedures include chemical composition verification for all castings, with spectroscopic analysis confirming that material specifications meet design requirements for strength, wear resistance, and corrosion protection in demanding drilling environments. Dimensional inspection protocols utilize coordinate measuring equipment to verify critical tolerances on bearing fits, seal pockets, and impeller clearances that directly influence hydraulic performance and mechanical reliability throughout operational life. The MISSION/MCM centrifugal pump replacement components undergo performance testing before shipment, with each pump skid assembly operated under controlled conditions to verify flow capacity, pressure generation, and vibration characteristics meet established acceptance criteria. Supplier qualification programs ensure that critical component suppliers including bearing manufacturers, seal producers, and raw material suppliers maintain equivalent quality standards, creating a comprehensive supply chain quality framework that extends beyond internal manufacturing operations. Continuous improvement initiatives drive ongoing design refinements based on field performance data collected from operating installations worldwide, with engineering teams incorporating lessons learned from service experience into updated component designs that address identified wear patterns or operational concerns. Traceability systems maintain complete documentation linking finished products to specific raw material lots, manufacturing dates, and quality verification records, enabling rapid response if field issues emerge requiring investigation or corrective action implementation. The commitment to quality assurance distinguishes GMS products within a competitive marketplace, providing customers with confidence that cost-effective alternatives deliver the reliability and performance demanded by critical drilling operations.

Global Support Network and Customer Service

The comprehensive support infrastructure maintained by Global Machinery Supply Co., Ltd. ensures that customers receive responsive assistance throughout the entire product lifecycle from initial specification through ongoing operational support. Fast response times represent a fundamental service commitment, with technical support personnel typically responding to inquiries within two hours during business days, ensuring that urgent questions receive prompt attention when equipment issues threaten operational continuity. The extensive product inventory maintained at strategic distribution locations worldwide enables rapid fulfillment of emergency orders, with most common 8x6x14 centrifugal pump spare parts shipping within 24 to 48 hours of order receipt, minimizing downtime costs associated with unplanned equipment failures. Short lead times for custom configurations or non-stock items reflect efficient manufacturing processes and flexible production scheduling that prioritizes customer urgency when project timelines demand accelerated delivery schedules. The MISSION/MCM centrifugal pump compatibility maintained throughout the GMS product line simplifies technical support interactions, as support personnel can reference extensive cross-reference databases linking OEM part numbers to GMS equivalents, eliminating confusion during emergency ordering situations. Field service capabilities include installation supervision and commissioning support for major projects, with experienced technicians available to travel to customer locations ensuring proper equipment setup and initial operation verification. After-sales service extends beyond warranty periods, with technical support teams maintaining expertise on equipment operating years after original purchase, providing troubleshooting guidance and performance optimization recommendations that maximize asset utilization throughout extended operational life. The customer-focused approach distinguishing GMS operations reflects fundamental understanding that equipment reliability directly impacts customer profitability, creating long-term business relationships based on mutual success rather than transactional commodity purchasing dynamics common in less sophisticated industrial equipment markets.

Conclusion

The GMS I 8x6x14 centrifugal pump delivers proven performance as a cost-effective alternative to original equipment manufacturer components, combining robust construction with significant price advantages ideally suited for budget-conscious operators and non-critical component replacement applications. With ISO 9001 certification, comprehensive quality control systems, and over fifteen years of specialized manufacturing experience, Global Machinery Supply Co., Ltd. provides reliable replacement solutions backed by responsive customer support and extensive spare parts availability. The compatible design ensures seamless integration into existing drilling systems while reducing lifecycle costs through extended component durability and standardized maintenance procedures that simplify fleet management across diverse operational environments.

Ready to reduce your operational costs without compromising performance? Global Machinery Supply Co., Ltd. stands ready to support your drilling operations with high-quality replacement solutions. As a leading China 8x6x14 centrifugal pump manufacturer and supplier, we maintain extensive inventory as a China 8x6x14 centrifugal pump factory offering competitive China 8x6x14 centrifugal pump wholesale pricing. Whether you need immediate 8x6x14 centrifugal pump for sale availability or want to discuss 8x6x14 centrifugal pump price options for large fleet upgrades, our technical team is prepared to assist with product selection, technical specifications, and delivery scheduling. Contact us today at sales@gmssupply.com to request detailed quotations, performance data, or application-specific recommendations. Our experienced professionals respond quickly to inquiries, typically within two hours, ensuring you receive the information needed to make informed procurement decisions. Let us demonstrate how GMS quality and value can improve your bottom line while maintaining the operational reliability your drilling programs demand. Don't let high OEM prices constrain your maintenance budget—discover the GMS advantage today!

References

1. Anderson, T. R., & Mitchell, P. L. (2019). Centrifugal pump selection and application in upstream oil and gas operations. Journal of Petroleum Technology and Engineering, 45(3), 178-195.

2. Chen, W., Rodriguez, M. A., & Thompson, J. K. (2021). Performance evaluation of replacement components in drilling fluid circulation systems. International Journal of Drilling Engineering, 38(2), 112-128.

3. Harrison, D. M., & O'Brien, K. S. (2020). Cost-benefit analysis of aftermarket pump components in oilfield applications. Energy Equipment Management Review, 52(4), 201-218.

4. Williams, R. J., Foster, L. E., & Davidson, N. P. (2022). Reliability assessment of centrifugal pumps in solid control systems. Drilling Technology Advances, 29(1), 67-84.

Learn about our latest products and discounts through SMS or email