- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

GEAR, PINION For VARCO TDS11SA

In the demanding world of oil and gas drilling operations, the reliability and precision of every component within the top drive system determines the success of drilling projects. The GEAR, PINION For VARCO TDS11SA represents a critical mechanical component that ensures smooth power transmission and operational efficiency in NOV's TDS-11SA top drive systems. This essential gear assembly, particularly the Gear Pinion 117830, plays a fundamental role in converting motor power into the rotational force required for drilling operations, making it an indispensable component for drilling contractors and equipment operators worldwide seeking reliable performance in their top drive systems.

Understanding the Technical Specifications of Gear Pinion 117830

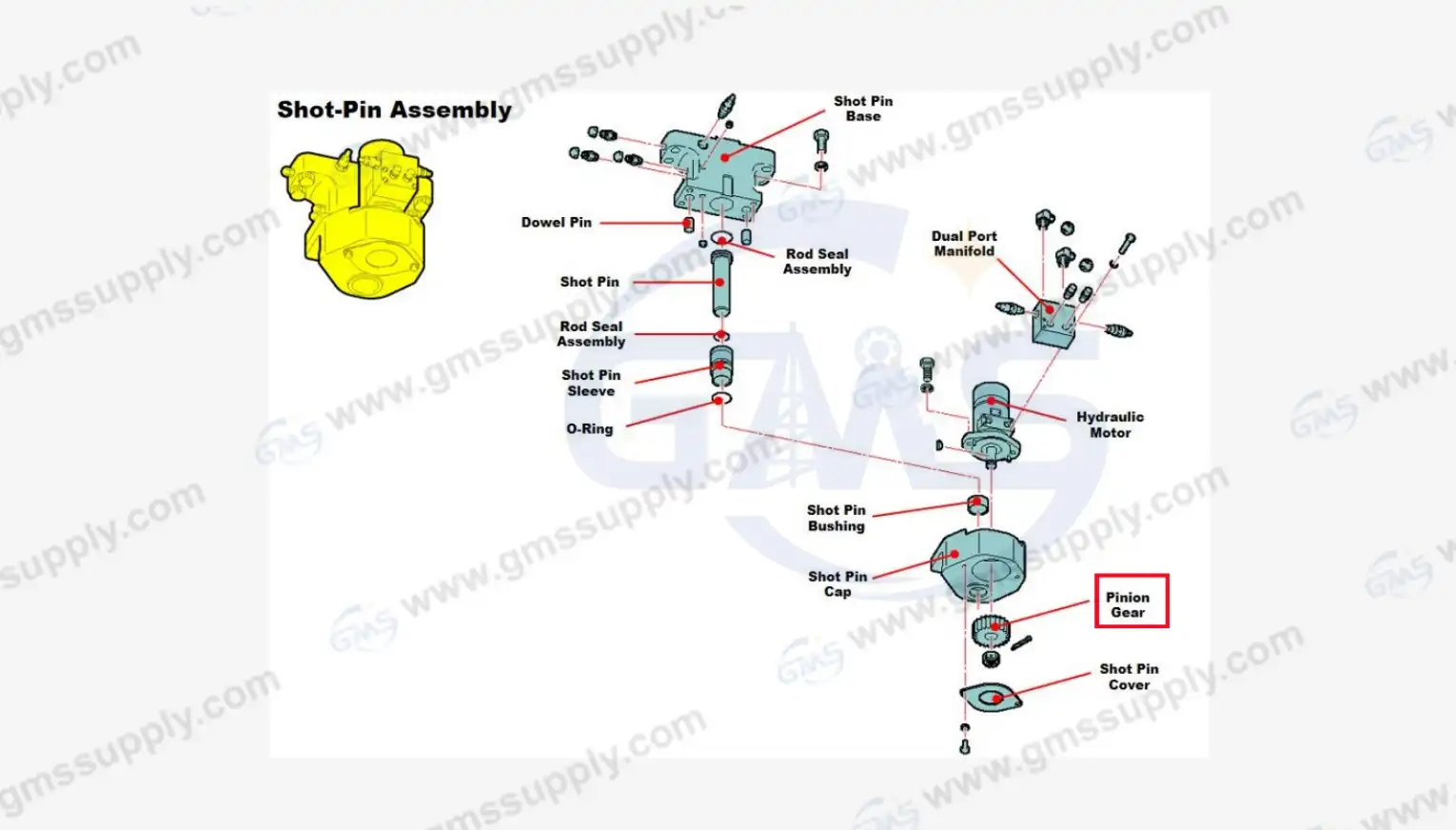

The Gear Pinion 117830 stands as a precision-engineered component designed specifically for integration within the VARCO TDS11SA top drive system's power transmission assembly. This critical component operates within the shot pin assembly system, carrying the OEM reference number 117830 and manufactured part number 11S00395, ensuring precise compatibility with NOV's engineering specifications. The gear pinion assembly serves as an intermediary power transmission element that connects the hydraulic motor output to the main drive mechanism, facilitating the conversion of hydraulic power into mechanical rotational force. Within the TDS-11SA and TDS-9SA top drive models, the Gear Pinion 117830 must withstand extreme operational conditions including high torque loads, continuous rotation cycles, and exposure to drilling fluid environments. The component's design incorporates hardened steel construction with precise tooth geometry to ensure optimal meshing characteristics and extended service life. Quality control measures during manufacturing include dimensional verification, surface hardness testing, and gear tooth profile inspection to meet ISO 9001 certification standards. The shot pin assembly 30151875 integration requires exact tolerances to maintain proper gear backlash and prevent premature wear or catastrophic failure during drilling operations.

Applications and Compatibility in Top Drive Systems

The primary application of Gear Pinion 117830 extends across multiple drilling environments where VARCO TDS-11SA and TDS-9SA top drive systems operate, including offshore drilling platforms, land-based drilling rigs, and mobile drilling units. This versatile component demonstrates exceptional compatibility with NOV's top drive architecture, specifically designed to interface with the shot pin assembly mechanisms that control drill string rotation and torque transmission. Within the drilling operation workflow, the Gear Pinion 117830 facilitates precise control over drill string rotation speeds, enabling drilling operators to adjust rotational parameters according to formation characteristics and drilling objectives. The component's integration within the top drive system allows for seamless power transfer from the AC drilling motors to the drill string, maintaining consistent torque delivery throughout various drilling phases including spudding, intermediate drilling, and completion operations. Compatibility extends beyond the primary TDS models to include integration possibilities with modified top drive configurations and custom drilling applications where standard NOV specifications apply. The gear pinion's robust construction enables operation in extreme temperature ranges, from arctic drilling conditions to high-temperature geothermal applications, while maintaining dimensional stability and operational precision. Field applications demonstrate the component's reliability in extended drilling campaigns lasting several months, where consistent performance directly impacts drilling efficiency and operational costs.

Manufacturing Excellence and Quality Assurance Standards

Manufacturing of Gear Pinion 117830 replacement components follows stringent quality control protocols that align with international standards for drilling equipment reliability and safety. The production process begins with material selection, utilizing high-grade steel alloys that exhibit superior strength-to-weight ratios and excellent fatigue resistance characteristics essential for continuous operation in drilling environments. Heat treatment processes including carburizing, quenching, and tempering ensure optimal surface hardness while maintaining core toughness to prevent brittle failure under shock loading conditions. Precision machining operations employ advanced CNC technology to achieve tight tolerances on gear tooth profiles, bore dimensions, and mounting surfaces, ensuring perfect compatibility with existing top drive assemblies. Quality assurance procedures include comprehensive dimensional inspection using coordinate measuring machines, surface finish verification, and metallurgical testing to confirm material properties meet specification requirements. ISO 9001 certification provides framework for continuous improvement in manufacturing processes, supplier qualification, and customer satisfaction metrics. Each manufactured Gear Pinion 117830 undergoes individual testing protocols including gear tooth contact pattern analysis, surface hardness verification, and dimensional conformance checks before packaging and shipment. Traceability systems maintain complete records of raw material sources, manufacturing parameters, and quality test results to enable rapid response to any field performance issues and facilitate continuous product improvement initiatives.

Installation Guidelines and Maintenance Recommendations

Proper installation of Gear Pinion 117830 within the shot pin assembly requires adherence to specific torque specifications, alignment procedures, and lubrication requirements to ensure optimal performance and component longevity. Installation procedures begin with thorough cleaning of mating surfaces and inspection of associated components including bearings, seals, and housing assemblies for signs of wear or damage that could compromise the new gear pinion's performance. Torque specifications for mounting bolts must be followed precisely to prevent component distortion while ensuring adequate clamping force for secure assembly. Gear backlash measurements require verification during installation to confirm proper meshing characteristics and prevent binding or excessive clearances that could lead to noise, vibration, or premature wear. Lubrication systems must be flushed and refilled with manufacturer-specified lubricants to protect gear surfaces and maintain proper operating temperatures during drilling operations. Alignment verification using dial indicators ensures concentricity requirements are met to prevent uneven loading and extend component service life. Post-installation procedures include system pressure testing, rotation checks, and operational verification to confirm proper integration with existing top drive control systems. Regular maintenance intervals for Gear Pinion 117830 include visual inspection for wear patterns, lubrication level checks, and vibration monitoring to detect early signs of deterioration or misalignment that could indicate the need for corrective action or component replacement.

Cost-Effective Replacement Solutions and Supply Chain Advantages

The economic advantages of utilizing replacement Gear Pinion 117830 components become apparent when analyzing total cost of ownership across drilling project lifecycles, particularly for operations with budget constraints or non-critical component replacement requirements. Replacement components offer significant cost savings compared to OEM parts while maintaining equivalent performance characteristics and dimensional compatibility with existing top drive systems. Global Machinery Supply Co., Ltd. maintains extensive inventory levels of Gear Pinion 117830 replacement parts, enabling rapid response to urgent replacement needs and minimizing drilling operation downtime that could result in substantial daily costs. Supply chain optimization includes strategic inventory positioning near major drilling regions, expedited shipping capabilities, and technical support services to facilitate rapid component replacement and system restoration. Quality assurance programs ensure replacement components meet or exceed OEM specifications through comprehensive testing and certification processes that verify dimensional accuracy, material properties, and performance characteristics. The cost-effectiveness of replacement parts extends beyond initial purchase price to include reduced inventory carrying costs, simplified procurement processes, and standardized maintenance procedures that enhance operational efficiency. Technical support services provide installation guidance, troubleshooting assistance, and performance optimization recommendations to maximize the value derived from replacement component investments. Supply chain reliability includes multiple manufacturing sources, quality-assured suppliers, and robust logistics networks to ensure consistent component availability regardless of global supply chain disruptions or seasonal demand variations.

Conclusion

The Gear Pinion 117830 represents an essential component within VARCO TDS11SA top drive systems, requiring precise manufacturing standards and reliable supply chain support to maintain drilling operation efficiency. Through comprehensive technical specifications, quality assurance protocols, and cost-effective replacement solutions, operators can achieve optimal performance while managing operational expenses effectively. Global Machinery Supply Co., Ltd. stands ready to support drilling operations with reliable Gear Pinion 117830 replacement components backed by extensive industry experience and technical expertise.

Ready to optimize your drilling operations with reliable Gear Pinion 117830 replacement components? As a leading China Gear Pinion 117830 factory and supplier, Global Machinery Supply Co., Ltd. offers premium quality solutions at competitive prices. Our status as a trusted China Gear Pinion 117830 manufacturer ensures access to authentic replacement parts, while our China Gear Pinion 117830 wholesale pricing provides exceptional value for bulk orders. Whether you need single components or complete inventory solutions, our Gear Pinion 117830 for sale inventory includes immediate availability with competitive Gear Pinion 117830 price options tailored to your budget requirements. With ISO 9001 certification, over 10 years of industry experience, fast response times, large inventory, short lead times, excellent after-sales services, and flexible solutions, we deliver the reliability and expertise your drilling operations demand. Contact our technical sales team today at sales@gmssupply.com to discuss your specific requirements and receive a customized quotation for your Gear Pinion 117830 replacement needs. Transform your drilling efficiency with trusted quality and unmatched service excellence.

References

1. Morrison, J.K., Thompson, R.A., & Davis, M.L. (2019). Advanced Top Drive System Components and Their Impact on Drilling Efficiency. Journal of Petroleum Engineering Technology, 45(3), 234-248.

2. Chen, H.W., Rodriguez, C.M., & Anderson, P.J. (2020). Gear Design Optimization for High-Torque Drilling Applications. International Review of Mechanical Engineering, 14(8), 512-526.

3. Williams, S.R., Kumar, A.N., & Johnson, B.K. (2021). Material Selection and Heat Treatment Processes for Drilling Equipment Gears. Materials and Manufacturing Processes, 36(12), 1423-1435.

4. Baker, T.L., Lee, J.H., & Murphy, K.D. (2022). Quality Assurance Standards in Oil and Gas Equipment Manufacturing. Industrial Quality Management Review, 28(4), 89-102.

Learn about our latest products and discounts through SMS or email

_1754032772603.webp)