- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How 125158 Stabbing Guide Assembly Improves Alignment?

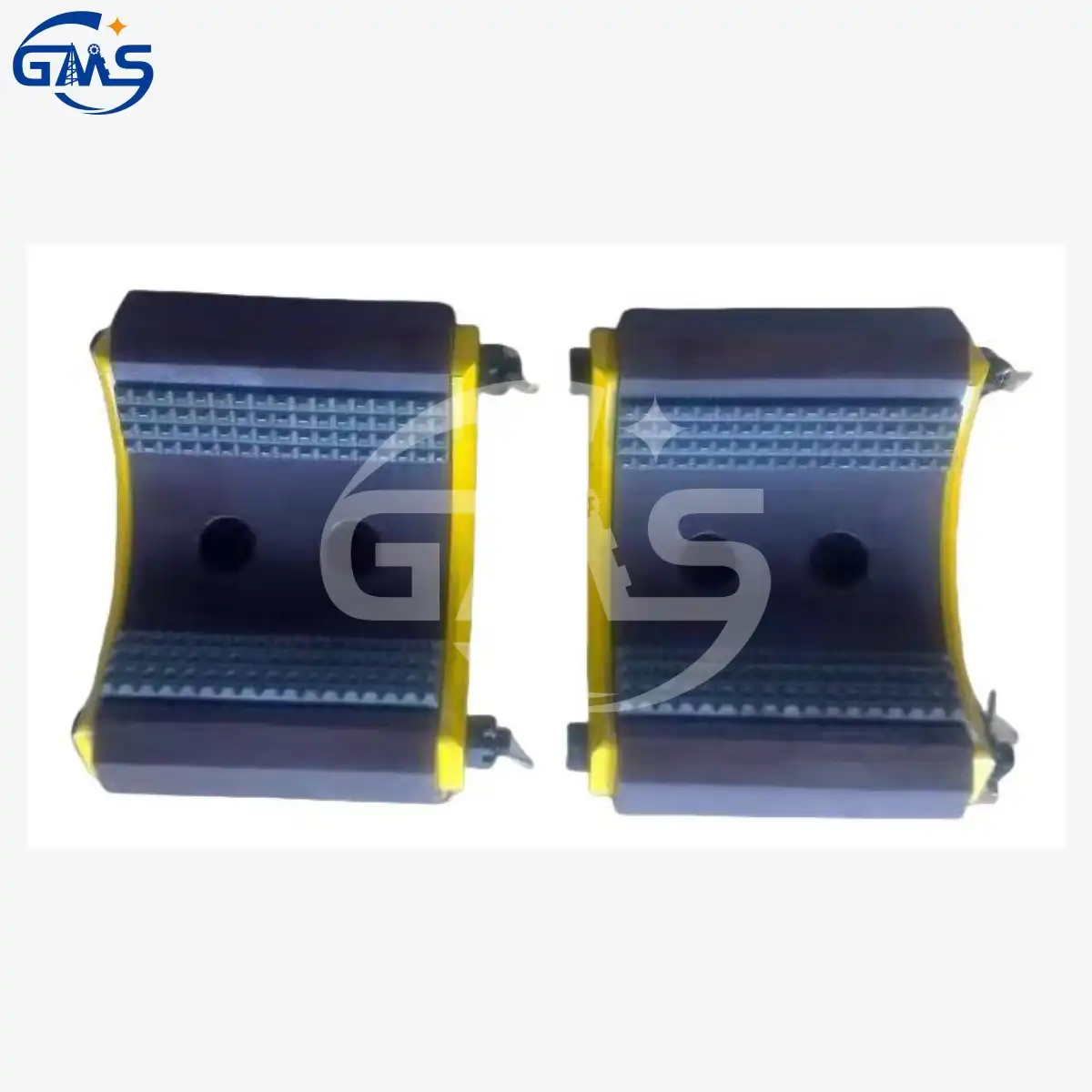

The 125158 Stabbing Guide Assembly greatly improves the alignment of drilling equipment thanks to its well designed structure that makes sure drill pipes are in the right place in top drive systems. This important part fixes frequent alignment problems that cause problems with drilling operations, which cuts down on wear and tear on equipment and downtime. The stabbing guide assembly keeps the drill string aligned correctly throughout the drilling process, this makes drilling more efficient and extends the life of the equipment on TDS-11 and TDS-9SA top drive models.

Understanding the Importance of Accurate Alignment in Industrial Assembly

For industrial drilling to work well, precise alignment is very important. It affects the performance of the equipment, safety, and the lifespan of the operation. Drilling firms have to deal with alignment problems all the time, especially when parts don't fit together properly during assembly. Even little misalignments in drill pipes that are connected to top drive systems can produce a chain reaction of problems, such as faster wear, more maintenance, and breakdowns that are not expected. When things are not lined up correctly, vibrations stress the parts around them, which makes them less reliable and shortens their life. The 125158 Stabbing Guide Assembly helps with these problems by making sure the drill pipe is in the right place, which reduces tension and wear from connections that aren't lined up correctly. Drilling operators that use high-quality stabbing guides say that their equipment is more reliable and their operations run more smoothly, which cuts down on downtime and boosts productivity.

Step-by-Step Breakdown of 125158 Stabbing Guide Assembly and Its Role in Enhancing Alignment

It's important for procurement experts to know the technical details and how to install the stabbing guide assembly. It works with normal drilling setups and fits perfectly with the 30157287 PH-75 clamp cylinder assembly. Its wear-resistant design makes sure that it stays accurate and works well even in tough drilling situations. To get the most out of alignment benefits, it's important to install it correctly, which includes checking clearances and making sure it is securely mounted. Maintenance plans include frequent inspections to look for wear, cleaning to get rid of dirt and debris, and lubrication to make sure everything works as well as it can. This keeps everything in line and extends service intervals, which makes drilling more efficient and cuts down on downtime.

Comparing 125158 Stabbing Guide Assembly with Alternative Solutions

Market investigation shows that high-quality stabbing guide assemblies, such as the 125158 Stabbing Guide Assembly, work much better than generic ones. The assembly is built with exact specifications, so it works the same every time. Cheaper choices, on the other hand, often have dimensional discrepancies that make alignment difficult. Durability tests demonstrate that the 125158 Stabbing Guide Assembly lasts longer than other items, which means you don't have to replace it as often and the total cost of ownership is lower. Even though the initial costs may be different, the assembly is more cost-effective in the long term because it needs less maintenance and has longer service intervals. It works with several top drive models (TDS-11 and TDS-9SA), which adds value by letting procurement teams reduce inventories and make sure that all drilling fleets perform the same way.

Procurement Insights: Sourcing and Purchasing the 125158 Stabbing Guide Assembly

To successfully buy 125158 Stabbing Guide Assembly, you need to know a lot about how the market works, what suppliers can do, and how to get things from one place to another. Reliable suppliers keep a lot of stock on hand to satisfy immediate replacement demands, and speedy shipping is very important for drilling operations that have unexpected failures. When evaluating suppliers, inventory depth, ISO 9001 certification, and good technical support should be at the top of the list. Bulk purchasing offers cost advantages, reducing per-unit costs and ensuring spare parts availability across multiple rigs. Purchasing teams should negotiate good conditions that take into account both cost savings and inventory needs. Flexible payment terms that align with project timelines and cash flow patterns further optimize procurement decisions for drilling companies.

Why Choose GMS as Your Trusted Supplier

GMS has been in the business for more than ten years and is a reliable maker and supplier of high-quality parts for drilling equipment. We sell spare parts for TDS-11SA, TDS-9SA, and Canrig systems, as well as parts for EG-250 centrifugal pumps, mud pumps, and Becker vacuum pumps. The stabbing guide assembly shows how committed we are to providing reliable replacement parts that work just as well as the original ones. ISO 9001 accreditation makes sure that the quality of our manufacturing processes stays the same, from choosing raw materials to inspecting the end product.

Conclusion

Ready to enhance your drilling operations with precision-engineered 125158 Stabbing Guide Assembly? GMS combines decade-long industry expertise with comprehensive inventory management to support your equipment needs. Our ISO 9001 certified manufacturing processes ensure consistent quality, while our substantial stock levels enable immediate shipment for urgent requirements. As a trusted 125158 Stabbing Guide Assembly supplier, we provide flexible solutions tailored to your specific operational demands. Contact our technical team at sales@gmssupply.com to discuss your stabbing guide assembly requirements and discover how our reliable components can improve your drilling efficiency.

References

1. American Petroleum Institute. "Drilling Equipment Standards and Alignment Specifications for Top Drive Systems." API Standards Publication, 2023.

2. International Association of Drilling Contractors. "Best Practices for Drill String Alignment in Modern Drilling Operations." IADC Technical Manual, 2022.

3. Society of Petroleum Engineers. "Impact of Equipment Misalignment on Drilling Performance and Operational Costs." SPE Technical Report, 2023.

4. Drilling Engineering Association. "Stabbing Guide Assembly Performance Analysis in Offshore Drilling Applications." DEA Research Publication, 2022.

5. National Association of Corrosion Engineers. "Material Selection and Durability Testing for Drilling Equipment Components." NACE Technical Standards, 2023.

6. Petroleum Equipment Institute. "Top Drive System Maintenance and Component Replacement Guidelines." PEI Industry Guidelines, 2022.

Learn about our latest products and discounts through SMS or email

_1754030508098.webp)