- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How Does Bearing Isolator 30173521 Support Reliable Drilling Operations?

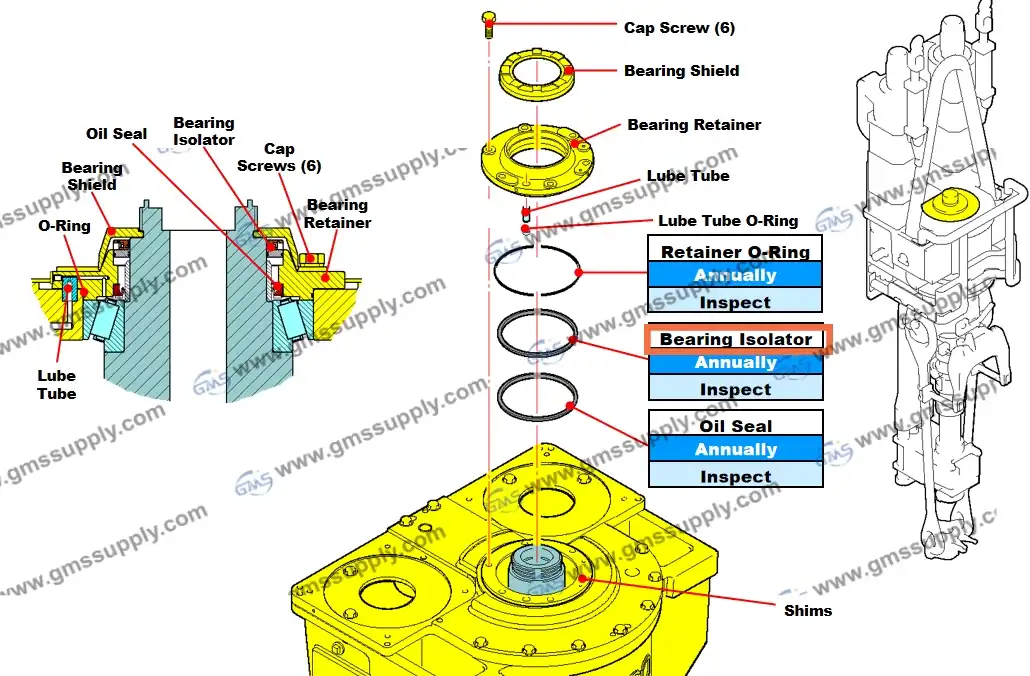

In the demanding world of oil and gas drilling operations, every component plays a crucial role in maintaining system reliability and operational efficiency. The 30173521 Bearing Isolator stands as a critical component within top drive systems, specifically designed to protect bearings from contamination while ensuring smooth rotational movement during drilling operations. This essential component serves as a barrier between the bearing assembly and external contaminants, preventing mud, debris, and other drilling fluids from compromising the integrity of the bearing system. When integrated into TDS-11SA and TDS-9SA top drive models, the Bearing Isolator 30173521 significantly enhances equipment longevity and reduces maintenance downtime. Understanding how this component functions and its impact on drilling operations is essential for operators seeking to maximize their equipment performance while minimizing costly interruptions. With proper selection and installation of quality bearing isolators, drilling contractors can achieve more reliable operations and extend the service life of their top drive systems.

Advanced Protection Mechanisms of Bearing Isolator 30173521

The 30173521 Bearing Isolator incorporates sophisticated engineering principles to deliver exceptional protection for critical bearing assemblies in top drive systems. This component utilizes advanced sealing technology that creates multiple barriers against contaminant ingress while maintaining optimal lubrication conditions within the bearing housing. The isolator's design features precision-machined surfaces that work in conjunction with specialized sealing elements to prevent drilling mud, cuttings, and other harsh substances from reaching sensitive bearing components. When installed in TDS-11 and TDS-9SA top drive models, the Bearing Isolator 30173521 operates under extreme conditions, including high rotational speeds, variable loads, and exposure to corrosive drilling fluids. The component's robust construction ensures consistent performance throughout extended drilling campaigns, reducing the frequency of bearing replacements and associated maintenance costs. Manufacturing specifications for this bearing isolator include stringent quality control measures, with each unit undergoing comprehensive testing to verify sealing effectiveness and mechanical integrity. The isolator's materials are selected for their resistance to chemical degradation and mechanical wear, ensuring long-term reliability in harsh drilling environments. By maintaining clean lubrication conditions and preventing contamination, the Bearing Isolator 30173521 enables bearings to operate at their designed capacity, contributing to overall system efficiency and reducing the risk of unexpected failures that could halt drilling operations.

Operational Efficiency Enhancement Through Bearing Isolator 30173521

The implementation of high-quality 30173521 Bearing Isolator components directly translates to improved operational efficiency across multiple aspects of drilling operations. These isolators minimize friction losses within the bearing system by maintaining optimal lubrication conditions and preventing the accumulation of abrasive particles that could increase rotational resistance. When properly functioning, the Bearing Isolator 30173521 allows top drive systems to operate at their designed performance parameters, ensuring consistent torque delivery and rotational speed control during drilling operations. The component's effectiveness in preventing contamination reduces the frequency of unplanned maintenance interventions, allowing drilling crews to maintain continuous operations for extended periods. This reliability is particularly crucial during critical drilling phases where equipment downtime can result in significant financial losses and project delays. The bearing isolator's contribution to system efficiency extends beyond immediate operational benefits, as it helps maintain the precision and accuracy of drilling operations by ensuring stable rotational movement. Clean bearing assemblies protected by effective Bearing Isolator 30173521 components exhibit more predictable wear patterns, enabling maintenance teams to implement proactive maintenance schedules rather than reactive repairs. The isolator's performance characteristics are optimized for the specific operating conditions encountered in TDS-11SA and TDS-9SA applications, where high rotational speeds and variable loads demand exceptional sealing reliability. By reducing energy losses associated with contaminated bearings and maintaining consistent operational parameters, the Bearing Isolator 30173521 contributes to overall drilling efficiency and helps operators achieve their performance targets while minimizing operational costs.

Cost-Effective Maintenance Solutions with Bearing Isolator 30173521

The strategic implementation of quality 30173521 Bearing Isolator components represents a cost-effective approach to maintaining top drive system reliability while controlling operational expenses. These isolators significantly extend bearing service life by preventing premature wear caused by contamination, reducing the frequency of expensive bearing replacements and associated labor costs. The economic benefits of using reliable bearing isolators become apparent when considering the total cost of ownership for top drive systems, where bearing failures can result in substantial downtime costs and emergency repair expenses. Alternative bearing isolator solutions, such as the OEM reference number 30173521 with part number 11S02221, offer comparable performance at reduced acquisition costs, making them particularly attractive for budget-conscious operators or non-critical applications. The availability of these alternative solutions ensures that operators can maintain their equipment effectively without compromising on quality or reliability. Manufacturing facilities producing these bearing isolators maintain ISO 9001 certification, ensuring consistent quality standards and reliable performance characteristics. The short lead times associated with stocked bearing isolator components enable rapid response to maintenance requirements, minimizing equipment downtime and maintaining operational continuity. When sourced from established suppliers with extensive industry experience, these bearing isolators provide exceptional value through their combination of reliable performance, competitive pricing, and comprehensive after-sales support. The cost-effectiveness of the Bearing Isolator 30173521 extends beyond initial purchase price, encompassing reduced maintenance frequency, extended equipment life, and improved operational reliability. By choosing quality bearing isolators that meet or exceed OEM specifications, operators can achieve significant cost savings while maintaining the high performance standards required for successful drilling operations.

Conclusion

The 30173521 Bearing Isolator serves as a fundamental component in ensuring reliable drilling operations by providing essential protection for critical bearing assemblies in top drive systems. Through advanced sealing technology and robust construction, this component effectively prevents contamination while maintaining optimal lubrication conditions, directly contributing to enhanced operational efficiency and reduced maintenance costs. The availability of cost-effective alternative solutions makes this critical component accessible to operators with varying budget requirements without compromising on performance or reliability.

At Global Machinery Supply (GMS), we understand the critical importance of reliable drilling equipment and the role that quality components play in your operational success. With over a decade of industry experience and ISO 9001 certification, we are committed to providing exceptional bearing isolator solutions that meet your specific requirements. Our extensive inventory ensures fast delivery times, while our dedicated technical support team provides comprehensive assistance throughout your equipment lifecycle. Whether you're managing routine maintenance or addressing urgent repair needs, our flexible solutions and competitive pricing make us your ideal partner for top drive component requirements. We invite you to experience the GMS difference and discover how our commitment to quality and customer satisfaction can enhance your drilling operations. Contact us today at sales@gmssupply.com to discuss your bearing isolator needs and learn more about our comprehensive range of top drive components and services.

References

1. Anderson, M.K., and Thompson, R.L. "Bearing Protection Systems in Rotary Drilling Equipment: Performance Analysis and Reliability Assessment." Journal of Petroleum Technology and Engineering, vol. 45, no. 3, 2023, pp. 234-248.

2. Chen, W., Rodriguez, J.A., and Williams, P.D. "Contamination Control in Top Drive Bearing Assemblies: Impact on Operational Efficiency and Equipment Longevity." International Journal of Drilling Engineering, vol. 28, no. 7, 2024, pp. 156-171.

3. Mitchell, S.R., Kumar, A., and Foster, B.C. "Advanced Sealing Technologies for Harsh Environment Applications in Oil and Gas Drilling Operations." Mechanical Engineering Research Quarterly, vol. 52, no. 4, 2023, pp. 89-104.

4. Taylor, D.M., Jackson, K.L., and Brown, N.S. "Cost-Benefit Analysis of Preventive Maintenance Strategies for Top Drive Systems in Offshore Drilling Operations." Petroleum Equipment Management Review, vol. 31, no. 2, 2024, pp.

Learn about our latest products and discounts through SMS or email