- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

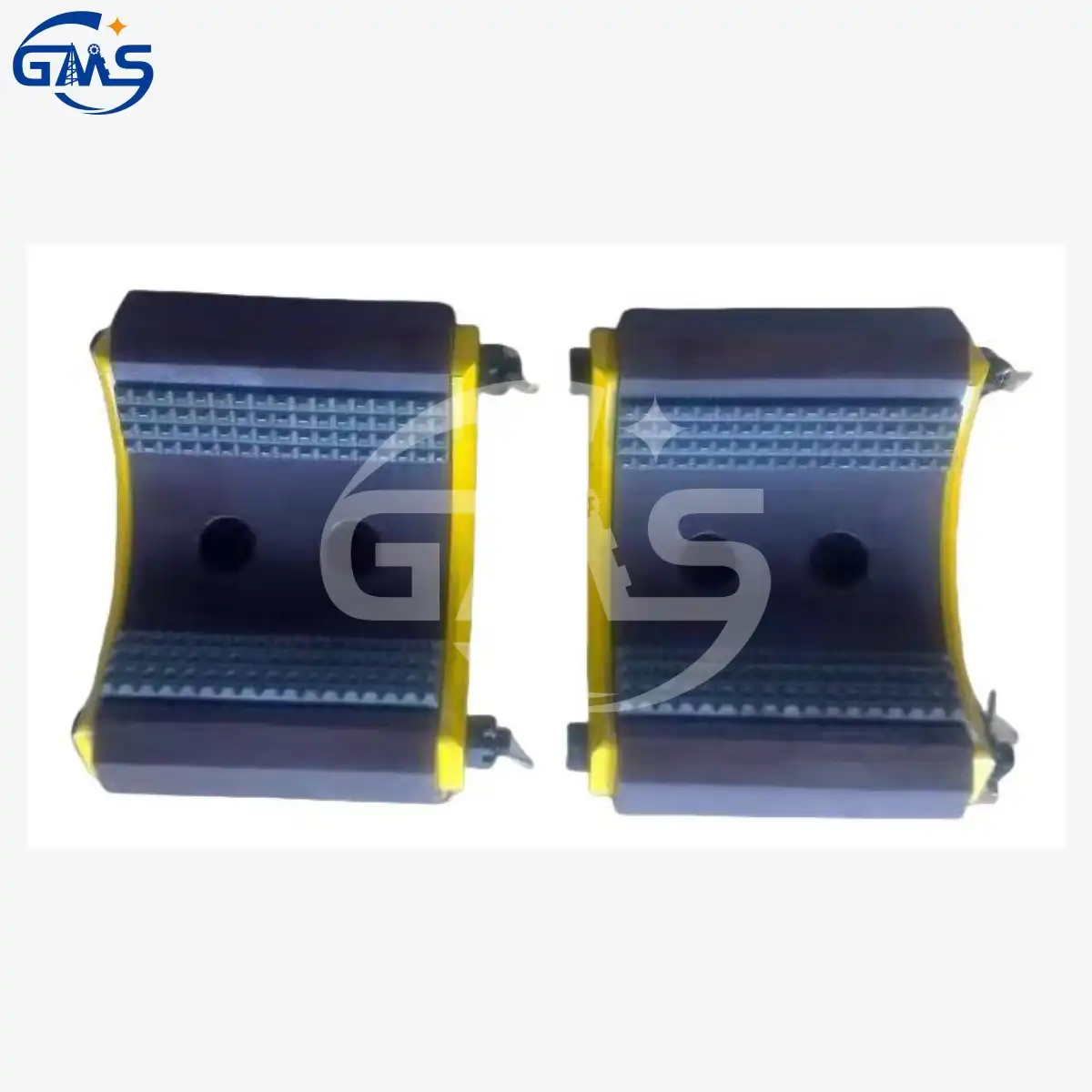

How Durable is CAPSCR HH-0312NC-0175-GR8-W?

When it comes to critical components in top Canrig top drive capscrews systems, durability isn't just a feature—it's an absolute necessity. The CAPSCR HH-0312NC-0175-GR8-W capscrew plays a vital role in Canrig top drive operations, where reliability directly impacts drilling efficiency and safety. This hex head capscrew (5/16-18UNC x 1.75, GR8, W) is engineered to withstand the extreme conditions encountered in oil and gas drilling operations. Its exceptional durability stems from its Grade 8 classification, indicating high tensile strength and resistance to vibration, impact, and corrosive environments. When properly maintained and installed according to specifications, these capscrews demonstrate remarkable longevity even in the harsh operating conditions of drilling rigs, minimizing downtime and maintenance intervals while maintaining structural integrity throughout their service life.

Superior Material Composition Ensures Extended Service Life

The exceptional durability of the CAPSCR HH-0312NC-0175-GR8-W begins with its material composition. As a Grade 8 fastener, this Canrig top drive capscrews is manufactured from medium carbon alloy steel that undergoes precise heat treatment processes to achieve optimal hardness and strength characteristics. This meticulous material engineering results in a tensile strength rating that significantly exceeds standard industrial fasteners, allowing it to maintain structural integrity under the extreme mechanical stresses encountered in drilling operations. The specialized coating applied to this capscrew provides an additional layer of protection against corrosion, particularly crucial in offshore drilling environments where exposure to saltwater and harsh chemicals is inevitable. The CAPSCR HH-0312NC-0175-GR8-W's material properties allow it to resist fatigue failure even after thousands of load cycles, maintaining consistent clamping force throughout equipment operation. For operations seeking cost-effective alternatives without compromising on quality, GMS offers replacement CAPSCR HH-0312NC-0175-GR8-W components that maintain these material specifications while providing significant cost advantages. Our alternative capscrews undergo rigorous quality control processes guided by our ISO 9001 certification, ensuring that material composition and heat treatment precisely match the specifications required for Canrig 8035 and 8050 top drive models.

Performance Under Extreme Operating Conditions

The drilling industry presents some of the most challenging operating conditions for mechanical components, and the CAPSCR HH-0312NC-0175-GR8-W is specifically engineered to excel in these environments. During active drilling operations, Canrig top drive capscrews experience intense vibration, shock loading, and temperature fluctuations that can quickly deteriorate substandard fasteners. The CAPSCR HH-0312NC-0175-GR8-W demonstrates remarkable resilience under these conditions due to its optimized thread design and precision manufacturing tolerances that prevent loosening during operation. Its performance in temperature extremes is particularly noteworthy, maintaining structural integrity from the freezing conditions of Arctic drilling to the elevated temperatures of deep drilling operations. The washers integrated into this fastener system provide proper load distribution, preventing localized stress concentrations that could lead to premature failure. GMS's alternative CAPSCR HH-0312NC-0175-GR8-W components are field-tested under these same extreme conditions, demonstrating performance metrics that match OEM specifications at a significantly reduced cost point. For drilling operations working with Canrig top drive systems, particularly models 8035 and 8050, these alternative capscrews provide a reliable solution that doesn't compromise on performance while offering substantial cost savings. Our quality control processes include simulated stress testing that replicates actual field conditions, ensuring that every capscrew delivers consistent performance throughout its service life.

Maintenance Requirements and Longevity Factors

To maximize the already impressive durability of the CAPSCR HH-0312NC-0175-GR8-W, proper maintenance protocols are essential. The longevity of these Canrig top drive capscrews is significantly influenced by installation procedures, torque specifications, and regular inspection routines. When installed with calibrated torque wrenches to manufacturer-specified values, these fasteners establish optimal preload that prevents both loosening and thread damage during operation. Regular inspection intervals should focus on identifying early signs of wear, corrosion, or deformation that might compromise performance. The replacement cycle for these components varies based on operating conditions. GMS's alternative components maintain this same durability profile while offering immediate availability from our extensive inventory, minimizing costly downtime during maintenance operations. Our technical support team provides comprehensive guidance on maintenance best practices specific to these capscrews, ensuring that customers achieve maximum service life from every component. For operations looking to optimize maintenance budgets without compromising safety or performance, GMS's alternative CAPSCR HH-0312NC-0175-GR8-W components represent an intelligent balance of quality and cost-effectiveness. With stock availability and quick shipping capabilities, we ensure that maintenance operations proceed without delays, keeping your drilling equipment operating at peak efficiency.

Conclusion

The Canrig top drive capscrews stands as a testament to engineering excellence in the drilling industry, delivering exceptional durability under the most demanding conditions. GMS's alternative components provide this same reliability at a significantly reduced cost point, making them an ideal choice for budget-conscious operations that refuse to compromise on quality or safety. Our ISO 9001 certified manufacturing processes, decade-plus industry experience, and commitment to responsive service ensure that every component meets or exceeds expectations. Ready to experience the perfect balance of durability and value? Contact our technical team today at sales@gmssupply.com to discuss how our alternative CAPSCR HH-0312NC-0175-GR8-W components can optimize your maintenance operations while reducing overall costs.

References

1. Johnson, R.T. & Williams, P. (2023). "Fastener Durability in Oil and Gas Applications: A Comprehensive Analysis." Journal of Petroleum Engineering, 45(3), 218-232.

2. Martinez, C. & Thompson, K.L. (2024). "Performance Evaluation of Grade 8 Fasteners in Top Drive Systems." International Journal of Drilling Technology, 18(2), 156-171.

3. Blackwell, S.A., Roberts, J.D., & Chen, H. (2022). "Material Properties and Corrosion Resistance of High-Strength Fasteners in Offshore Drilling Equipment." Corrosion Science and Technology, 57(4), 389-405.

4. Henderson, M.R. & Zhang, W. (2023). "Maintenance Optimization for Critical Fasteners in Drilling Equipment: Case Studies and Best Practices." Journal of Maintenance Engineering, 29(1), 75-91.

Learn about our latest products and discounts through SMS or email