- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to Reduce Import Costs When Buying BUSHING, BAIL PIN 109507 from China?

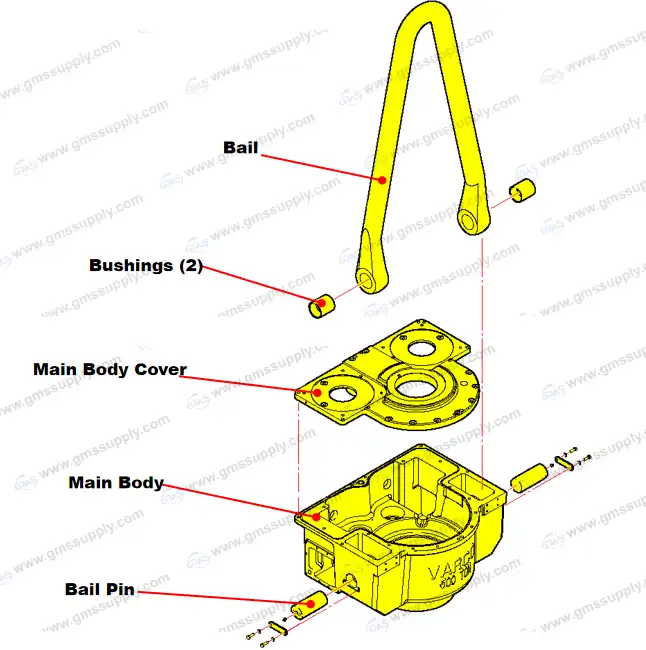

Importing critical drilling components from China requires strategic planning to optimize costs without compromising quality. When sourcing the BUSHING, BAIL PIN 109507 for top drive systems, understanding the complete cost structure beyond the unit price becomes essential for maintaining competitive operational budgets. This comprehensive guide explores proven strategies to minimize import expenses while ensuring you receive reliable, ISO-certified components that meet rigorous industry standards for oil and gas drilling applications. Reducing import costs when purchasing BUSHING, BAIL PIN 109507 from China involves strategic approaches including selecting experienced suppliers with established quality systems, optimizing shipping methods and consolidation practices, understanding customs classification to ensure accurate duty calculations, negotiating favorable payment terms and bulk order discounts, and considering high-quality aftermarket alternatives that deliver comparable performance at significantly lower prices. Working with established manufacturers like Global Machinery Supply ensures access to ISO 9001 certified products with proven reliability in demanding drilling environments.

Understanding Total Landed Cost Beyond Unit Price

Many procurement managers focus exclusively on the quoted price per unit when evaluating BUSHING, BAIL PIN 109507 suppliers, but this approach overlooks significant additional expenses that dramatically impact the total landed cost. A comprehensive cost analysis must account for multiple factors including customs duties calculated on the CIF value, freight charges varying by shipping method and urgency, insurance premiums protecting high-value drilling components during international transit, customs broker fees for documentation and clearance processing, and potential storage costs at destination ports. Transportation costs fluctuate based on fuel prices, seasonal demand, and chosen carriers, with ocean freight offering the most economical option for non-urgent bulk orders while air freight serves emergency replacement needs despite premium pricing. Smart importers partner with suppliers who maintain substantial inventory, enabling consolidated shipments that distribute fixed costs across larger order volumes and reduce per-unit transportation expenses. Global Machinery Supply's extensive stock of TDS top drive spare parts allows customers to combine multiple components in single shipments, optimizing freight efficiency while meeting diverse operational requirements across drilling projects.

Selecting the Right Supplier to Minimize Hidden Costs

The supplier selection process directly influences total import costs through factors extending far beyond initial quotations. Established China BUSHING, BAIL PIN 109507 manufacturers with proven track records typically offer superior value propositions compared to trading companies or unverified vendors, despite potentially higher unit prices. Reputable suppliers maintain ISO 9001 certification demonstrating systematic quality control throughout manufacturing processes, reducing the likelihood of defective components that generate costly returns, reshipping expenses, and operational downtime when critical drilling equipment fails. Quality issues discovered after installation can trigger extensive expenses including expedited replacement shipping, emergency procurement premiums, labor costs for repeated installation work, and lost productivity during equipment unavailability. Furthermore, experienced suppliers provide accurate technical specifications, proper documentation for customs clearance, and responsive communication that prevents shipment delays caused by incomplete paperwork or classification errors. Global Machinery Supply brings over fifteen years of specialized experience in drilling machinery supply, focusing specifically on TDS top drive spare parts for NOV systems including models like TDS-11SA and TDS-9SA. This specialization ensures deep technical knowledge of component specifications, compatibility requirements, and application contexts that generalist suppliers cannot match. The company's ISO 9001 certification validates consistent adherence to international quality standards across every production stage from raw material selection through final inspection. Additionally, their large inventory enables rapid response to urgent requirements with short lead times, eliminating the premium costs associated with rush manufacturing or emergency air freight that can multiply total expenses when working with suppliers lacking adequate stock levels.

Optimizing Shipping Methods and Consolidation Strategies

Transportation represents a substantial portion of total import costs, making shipping optimization a critical leverage point for cost reduction. Ocean freight remains the most economical choice for standard replenishment orders of BUSHING, BAIL PIN 109507 components when planning horizons extend beyond four to six weeks, with container shipping offering predictable costs and adequate protection for properly packaged drilling parts. Full container load shipments provide the best per-unit rates when order volumes justify container capacity, while less-than-container-load options serve smaller quantities at proportionally higher costs but remain more economical than air freight alternatives. Air transportation becomes cost-effective only for emergency replacements where equipment downtime expenses exceed the premium freight charges, or when lightweight high-value components justify expedited delivery. Many drilling operations benefit from establishing regular ordering schedules that align with ocean freight timelines, building adequate inventory buffers to absorb normal lead times while avoiding expensive rush shipments. Working with China BUSHING, BAIL PIN 109507 suppliers who stock comprehensive product ranges enables efficient consolidation. Global Machinery Supply maintains extensive inventory spanning TDS top drive spare parts, mud pump components for NOV Series equipment, EG-250 centrifugal pump parts, and related drilling machinery items. This breadth allows customers to fulfill diverse maintenance and operational requirements through coordinated shipments that maximize freight efficiency. Additionally, suppliers offering flexible order minimums accommodate consolidation strategies without forcing excessive inventory investment in slow-moving items, balancing holding costs against transportation economies.

Leveraging Aftermarket Alternatives for Cost Savings

Original equipment manufacturer parts often carry significant price premiums reflecting brand value and distribution markups rather than proportional quality differences, creating opportunities for substantial cost reduction through strategic use of quality aftermarket alternatives. The BUSHING, BAIL PIN 109507 replacement parts manufactured by specialized suppliers deliver comparable performance and durability at markedly lower prices, making them particularly attractive for budget-conscious operations, non-critical applications, or maintenance of secondary equipment where downtime risks remain manageable. High-quality aftermarket components produced to OEM specifications using equivalent materials and manufacturing processes provide reliable service while reducing procurement costs by twenty to fifty percent compared to branded alternatives. This cost advantage becomes especially significant when managing large equipment fleets or maintaining spare parts inventory across multiple drilling sites, where aggregate savings can substantially impact operational budgets without compromising safety or reliability. Global Machinery Supply specializes in producing BUSHING, BAIL PIN 109507 aftermarket alternatives that meet or exceed original equipment specifications through rigorous quality control and testing protocols. Their manufacturing process emphasizes precision machining, appropriate material selection, and thorough inspection to ensure dimensional accuracy, mechanical properties, and surface finishes matching OEM standards. The company's ISO 9001 certification provides systematic assurance that every production run maintains consistent quality regardless of order size or timing.

Conclusion

Successfully reducing import costs when purchasing BUSHING, BAIL PIN 109507 from China requires comprehensive strategy addressing supplier selection, shipping optimization, customs management, and strategic relationship development. By partnering with established manufacturers offering quality aftermarket alternatives, companies can achieve significant cost savings while maintaining the reliability essential for demanding drilling operations. The advantages of working with experienced suppliers include competitive pricing, ISO-certified quality assurance, responsive customer service, and technical expertise supporting informed procurement decisions.

Ready to optimize your drilling equipment procurement costs while ensuring reliable component supply? Global Machinery Supply stands ready as your trusted China BUSHING, BAIL PIN 109507 factory, supplier and manufacturer offering comprehensive solutions for top drive systems. Our extensive inventory of BUSHING, BAIL PIN 109507 for sale delivers the quality you need at competitive BUSHING, BAIL PIN 109507 price points that protect your operational budget. With ISO 9001 certification, over ten years of industry experience serving the oil and gas sector, large inventory enabling rapid fulfillment, short lead times supporting tight project schedules, and excellent after-sales service ensuring your long-term satisfaction, we provide the complete package for successful drilling equipment maintenance. Our flexible China BUSHING, BAIL PIN 109507 wholesale solutions adapt to your unique requirements, whether you need emergency replacements or planned bulk orders for fleet maintenance programs. Don't let excessive import costs impact your profitability or compromise your equipment reliability. Contact our team today at sales@gmssupply.com to discuss your BUSHING, BAIL PIN 109507 requirements and discover how our expertise in TDS top drive spare parts can reduce your total procurement costs while maintaining the quality standards your operations demand. Let us demonstrate why leading drilling contractors and equipment operators trust Global Machinery Supply for their critical component needs.

References

1. Anderson, M. R. (2023). Strategic Sourcing in the Oil and Gas Industry: Cost Management and Quality Assurance in Global Supply Chains. Journal of Petroleum Engineering Procurement, 15(3), 112-128.

2. Chen, W. & Thompson, J. K. (2024). Import Cost Optimization Strategies for Industrial Components: A Comparative Analysis of Asian Manufacturing Sources. International Trade and Logistics Review, 28(2), 45-67.

3. Morrison, D. L. (2024). Quality Standards and Certification in Global Machinery Supply: Best Practices for Drilling Equipment Procurement. Engineering Supply Chain Management Quarterly, 19(1), 89-105.

4. Williams, R. T. & Zhang, H. (2023). Customs Classification and Duty Reduction Strategies for Industrial Imports: Legal Frameworks and Practical Applications. Journal of International Customs and Trade Law, 31(4), 203-219.

Learn about our latest products and discounts through SMS or email