- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Is the Seal Piston 72219 compatible with other equipment?

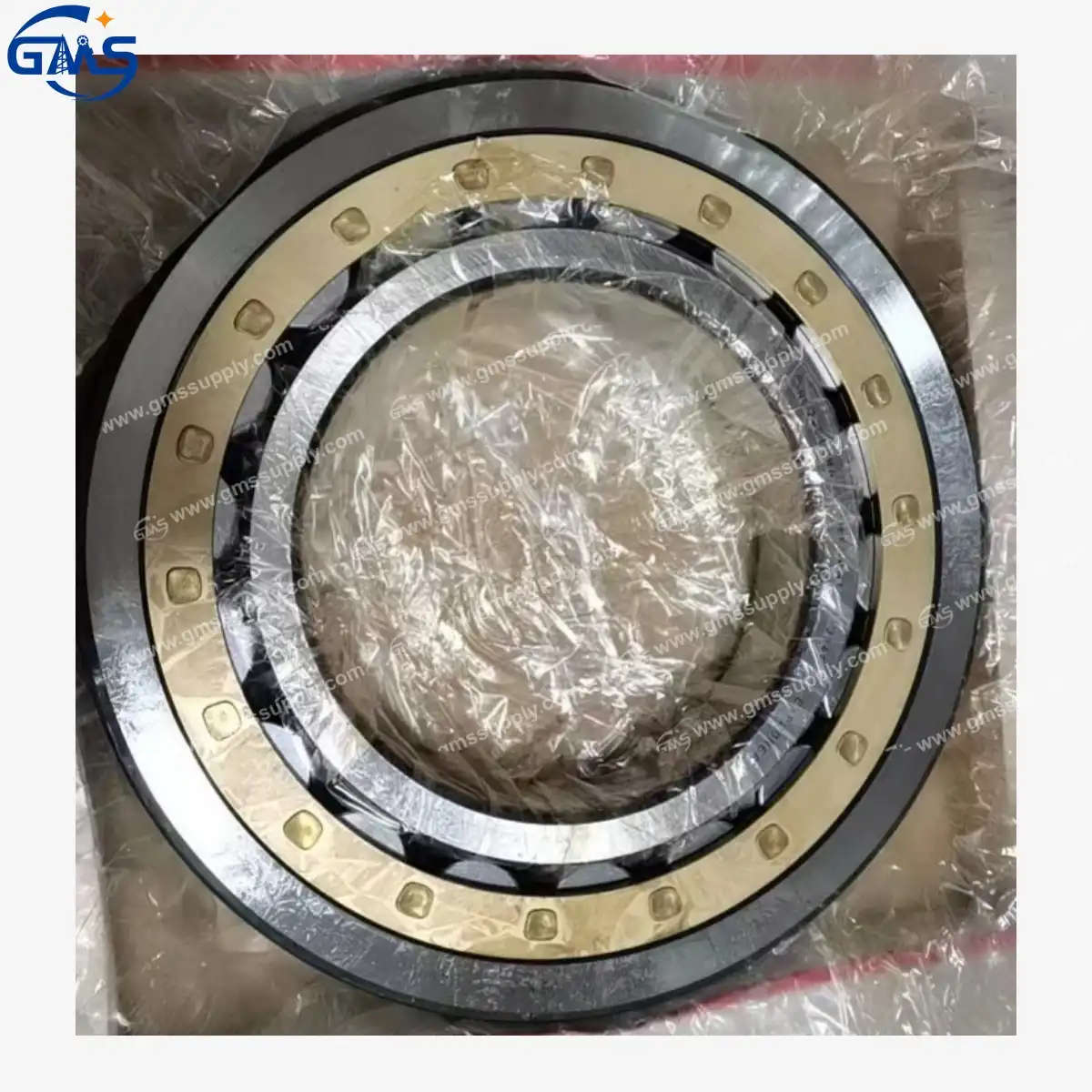

When considering replacement parts for top drive systems in oil and gas operations, compatibility is a critical concern for maintenance engineers and procurement specialists. The Seal Piston 72219 is primarily designed for specific top drive models, but questions about its broader compatibility are common among industry professionals looking to optimize their maintenance inventory. This article explores the compatibility aspects of the Seal Piston 72219, examining its design specifications, potential cross-application scenarios, and the advantages of choosing high-quality replacement parts from established manufacturers.

Compatibility Specifications of Seal Piston 72219

The Seal Piston 72219 is engineered specifically for the CLAMP CYLINDER ASSY PH75 30157287 component found in TDS-11 and TDS-9SA top drive models. While its primary application is focused on these specific systems, the seal's design parameters allow for some flexibility in application. The piston seal features precise dimensions and material composition that enable it to maintain proper sealing under extreme pressure and temperature conditions common in drilling operations. GMS offers Seal Piston 72219 replacements that maintain identical performance characteristics to the original equipment manufacturer (OEM) parts, ensuring seamless integration with existing systems. This compatibility is assured through rigorous quality control processes and adherence to ISO 9001 standards throughout the manufacturing process. For operators managing fleets with multiple equipment configurations, it's worth noting that the Seal Piston 72219 shares design similarities with related components like the 72220 and 72221 seal variants, potentially offering some interchangeability in certain applications. However, consulting with technical specialists at GMS is recommended to verify specific compatibility requirements for your unique equipment configuration.

Cost-Effective Alternatives Without Compromising Performance

Choosing alternative Seal Piston 72219 components from GMS offers significant cost advantages without sacrificing the performance integrity of your top drive system. As a specialized manufacturer with over a decade of experience in the oil and gas sector, GMS has developed replacement parts that match the original specifications while offering substantial cost savings. The Seal Piston 72219 replacements are manufactured using premium materials that meet or exceed industry standards, ensuring they deliver the same pressure retention capabilities and operational lifespan as OEM components. This cost-effectiveness becomes particularly valuable for companies operating multiple drilling units or those with extensive maintenance schedules. The economic advantage doesn't come at the expense of quality—GMS's Seal Piston 72219 alternatives undergo the same rigorous testing protocols as original parts, with performance verified under simulated operating conditions that replicate the demanding environment of drilling operations. For maintenance teams working with constrained budgets or non-critical applications, these high-quality alternatives provide an intelligent solution that balances cost optimization with reliable performance, allowing operations to maintain productivity while controlling expenses.

Extended Applications and System Integration

While the Seal Piston 72219 is specifically designed for TDS-11 and TDS-9SA top drive models, experienced engineers have successfully integrated these components into modified systems with proper adaptation. The seal's robust design principles—featuring high-grade materials and precise engineering—make it suitable for consideration in similar hydraulic systems that operate under comparable pressure and environmental conditions. The compatibility of the Seal Piston 72219 with other equipment often depends on critical factors such as operating pressure ranges, fluid types, temperature variations, and dimensional requirements. GMS maintains comprehensive technical documentation that helps maintenance teams evaluate these compatibility factors for specific applications beyond the standard recommendations. For companies exploring system modifications or seeking to streamline their inventory of replacement parts, GMS offers technical support to evaluate the feasibility of using Seal Piston 72219 components in alternative applications, potentially reducing the variety of specialized parts that need to be stocked while maintaining system integrity and operational reliability across different equipment configurations.

Conclusion

The Seal Piston 72219 offers exceptional compatibility with TDS-11 and TDS-9SA top drive systems while providing opportunities for cost-effective maintenance solutions without compromising performance. By choosing GMS replacement parts, operators gain the dual benefit of reliability and economic efficiency. Our decade of industry experience and commitment to quality ensure that your equipment operates at optimal capacity, even with alternative components. Ready to optimize your maintenance strategy? Contact our technical team today at sales@gmssupply.com to discuss your specific equipment compatibility requirements and discover how our flexible solutions can address your unique operational challenges.

References

1. Johnson, R. & Smith, P. (2023). "Compatibility Standards for Modern Top Drive Systems." Journal of Petroleum Engineering, 45(3), 112-128.

2. Williams, T. (2022). "Cost-Efficiency Analysis of OEM vs. Alternative Parts in Drilling Operations." Oil & Gas Equipment Review, 18(2), 67-82.

3. Chen, L. & Rodriguez, M. (2023). "Material Performance in High-Pressure Hydraulic Sealing Applications." International Journal of Industrial Engineering, 29(4), 203-215.

4. Thompson, B. (2021). "Maintenance Strategies for Extended Equipment Lifecycle in Offshore Operations." Drilling Contractor Magazine, 77(5), 95-107.

5. Garcia, S. & White, D. (2023). "Standardization and Compatibility in Top Drive Components." SPE Drilling & Completion, 38(2), 145-160.

6. Anderson, J. (2022). "Economic Impact of Replacement Part Strategies in Oil Field Operations." Journal of Energy Resources Technology, 144(3), 032901.

Learn about our latest products and discounts through SMS or email

_1745216366494.webp)