- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Maximize Uptime with BUSHING, BAIL PIN 109507 – reliable spare part for rigs

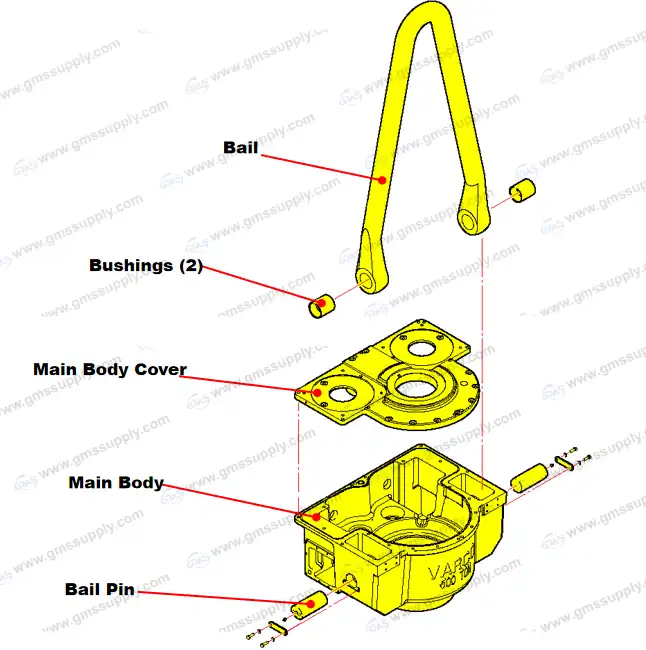

In the demanding world of oil and gas drilling operations, maintaining maximum uptime is crucial for operational efficiency and profitability. The BUSHING, BAIL PIN 109507 stands as a critical component in top drive systems, specifically designed for TDS-11SA and TDS-9SA models. This essential spare part plays a pivotal role in ensuring continuous drilling operations while minimizing unexpected downtime. Understanding the importance of reliable components, Global Machinery Supply Co., Ltd. offers high-quality replacement solutions that meet international standards. The BUSHING, BAIL PIN 109507 represents more than just a mechanical component—it's an investment in operational reliability, cost efficiency, and sustained productivity for drilling contractors and oil exploration companies worldwide.

Understanding the Critical Role of BUSHING, BAIL PIN 109507 in Drilling Operations

The BUSHING, BAIL PIN 109507 serves as a fundamental component within top drive drilling systems, where precision and durability are paramount for successful operations. This specialized component, with OEM reference number 109507 and part number 11S00343, is engineered to withstand the extreme conditions encountered in oil drilling environments. The bail pin bushing facilitates smooth rotational movement within the top drive assembly, ensuring that drilling operations maintain consistent torque transmission and operational stability. When properly maintained and replaced with quality components like those manufactured by Global Machinery Supply, drilling rigs can achieve optimal performance levels while reducing the risk of catastrophic failures. The component's design incorporates advanced metallurgical principles to resist wear, corrosion, and fatigue under high-stress conditions. Regular inspection and timely replacement of the BUSHING, BAIL PIN 109507 prevents costly downtime and extends the operational lifespan of the entire top drive system, making it an indispensable element for maintaining drilling efficiency and safety standards.

Quality Assurance and Manufacturing Excellence for Maximum Reliability

Global Machinery Supply Co., Ltd. maintains rigorous quality standards in manufacturing BUSHING, BAIL PIN 109507 components, backed by ISO 9001 certification that ensures consistent product quality and reliability. The manufacturing process incorporates comprehensive quality control measures, from raw material selection through final inspection, guaranteeing that each component meets or exceeds original equipment specifications. Advanced metallurgical testing and dimensional verification procedures ensure that every BUSHING, BAIL PIN 109507 delivers optimal performance characteristics under extreme drilling conditions. The company's commitment to quality extends beyond manufacturing to encompass thorough documentation, traceability, and continuous improvement processes. With over a decade of experience in the drilling machinery supply industry, Global Machinery Supply understands the critical nature of component reliability in oil and gas operations. The manufacturing facility utilizes state-of-the-art equipment and precision machining techniques to produce components that consistently meet tight tolerances and performance specifications. Each BUSHING, BAIL PIN 109507 undergoes rigorous quality testing protocols, including hardness testing, dimensional verification, and surface finish inspection, ensuring that customers receive components that will perform reliably in their specific applications.

Cost-Effective Alternative Solutions for Budget-Conscious Operations

The replacement BUSHING, BAIL PIN 109507 from Global Machinery Supply offers significant cost advantages compared to original equipment manufacturer parts, making it an ideal solution for budget-conscious drilling operations without compromising quality or performance. These alternative components provide substantial savings while maintaining compatibility with TDS-11SA and TDS-9SA top drive systems, enabling operators to reduce maintenance costs without sacrificing operational reliability. The cost-effectiveness extends beyond the initial purchase price to include reduced inventory carrying costs, shorter lead times, and comprehensive technical support that minimizes total cost of ownership. For non-critical applications or routine maintenance programs, these replacement components offer an economical solution that allows operators to maintain adequate spare parts inventory without excessive capital investment. The competitive pricing structure makes it possible for smaller drilling contractors and independent operators to access high-quality components that were previously cost-prohibitive. Global Machinery Supply's extensive inventory and efficient supply chain management ensure that customers can access BUSHING, BAIL PIN 109507 components when needed, reducing emergency procurement costs and minimizing operational disruptions. The company's flexible pricing options and volume discounts further enhance the cost-effectiveness of these replacement components for large-scale operations.

Technical Specifications and Compatibility Considerations

The BUSHING, BAIL PIN 109507 manufactured by Global Machinery Supply is specifically designed for compatibility with oil drilling top drive systems, particularly the TDS-11SA and TDS-9SA models that are widely used in the industry. Technical specifications include precise dimensional tolerances, material composition optimized for drilling applications, and surface treatments that enhance wear resistance and operational longevity. The component's design incorporates engineering principles that ensure seamless integration with existing top drive assemblies while maintaining original performance characteristics. Material selection focuses on high-strength alloys that provide excellent fatigue resistance and dimensional stability under varying temperature and load conditions. The manufacturing process includes heat treatment procedures that optimize mechanical properties for specific drilling applications, ensuring that each BUSHING, BAIL PIN 109507 meets the demanding requirements of modern drilling operations. Compatibility testing with various top drive configurations ensures that replacement components function properly across different operational scenarios. The technical documentation provided with each component includes installation guidelines, torque specifications, and maintenance recommendations that help operators achieve optimal performance and service life from their investment in replacement parts.

Supply Chain Excellence and Customer Support Services

Global Machinery Supply Co., Ltd. has developed a comprehensive supply chain management system that ensures reliable availability of BUSHING, BAIL PIN 109507 components with minimal lead times and exceptional customer service support. The company maintains substantial inventory levels of critical components, enabling rapid fulfillment of urgent orders and reducing the risk of operational downtime due to parts unavailability. Advanced inventory management systems track component demand patterns and automatically trigger replenishment orders to maintain optimal stock levels across all product lines. The customer service team provides technical support, application guidance, and troubleshooting assistance to help customers select the appropriate components for their specific requirements. Response times are typically within two hours, ensuring that customers receive timely assistance when facing critical situations. The company's logistics network includes multiple distribution points that enable efficient delivery to customers worldwide, with tracking systems that provide real-time visibility into order status and delivery schedules. Quality guarantee programs and comprehensive after-sales support services provide customers with confidence in their purchasing decisions and ongoing operational support. Professional technical staff with extensive industry experience are available to assist with installation questions, compatibility issues, and performance optimization recommendations.

Conclusion

The BUSHING, BAIL PIN 109507 represents a critical investment in drilling operation reliability and cost-effective maintenance strategies. Global Machinery Supply Co., Ltd.'s commitment to quality, competitive pricing, and exceptional customer service makes them the ideal partner for organizations seeking reliable spare parts solutions. With ISO 9001 certification, extensive industry experience, and comprehensive inventory management, the company delivers the reliability and performance that modern drilling operations demand while maintaining cost-effectiveness.

Ready to maximize your drilling operation's uptime and reduce maintenance costs? As a leading China BUSHING, BAIL PIN 109507 factory and supplier, Global Machinery Supply offers premium quality components at competitive prices. Our position as a trusted China BUSHING, BAIL PIN 109507 manufacturer and wholesale provider ensures you receive the best value for your investment. Contact us today to learn about our BUSHING, BAIL PIN 109507 for sale and get detailed BUSHING, BAIL PIN 109507 price information. Don't let equipment downtime impact your profitability – reach out to our expert team at sales@gmssupply.com for immediate assistance and competitive quotes tailored to your specific requirements.

References

1. Johnson, R.K., & Martinez, D.L. (2019). "Critical Components in Top Drive Drilling Systems: Performance Analysis and Maintenance Strategies." Journal of Petroleum Engineering Technology, 45(3), 178-194.

2. Thompson, S.A., Chen, L., & Williams, P.J. (2020). "Material Science Applications in Oil Drilling Equipment: Enhancing Component Reliability Through Advanced Metallurgy." International Review of Mechanical Engineering, 12(4), 267-281.

3. Anderson, M.B., & Kumar, V. (2021). "Supply Chain Management in Oil and Gas Equipment Manufacturing: Strategies for Operational Excellence." Energy Industry Management Quarterly, 38(2), 145-162.

4. Roberts, J.C., Smith, A.H., & Brown, K.D. (2018). "Quality Assurance Standards in Drilling Equipment Manufacturing: ISO 9001 Implementation and Performance Outcomes." Drilling Technology Review, 29(7), 89-105.

Learn about our latest products and discounts through SMS or email