- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Top Drive Reliability: 30151875 Shot Pin Assembly in Extreme Conditions

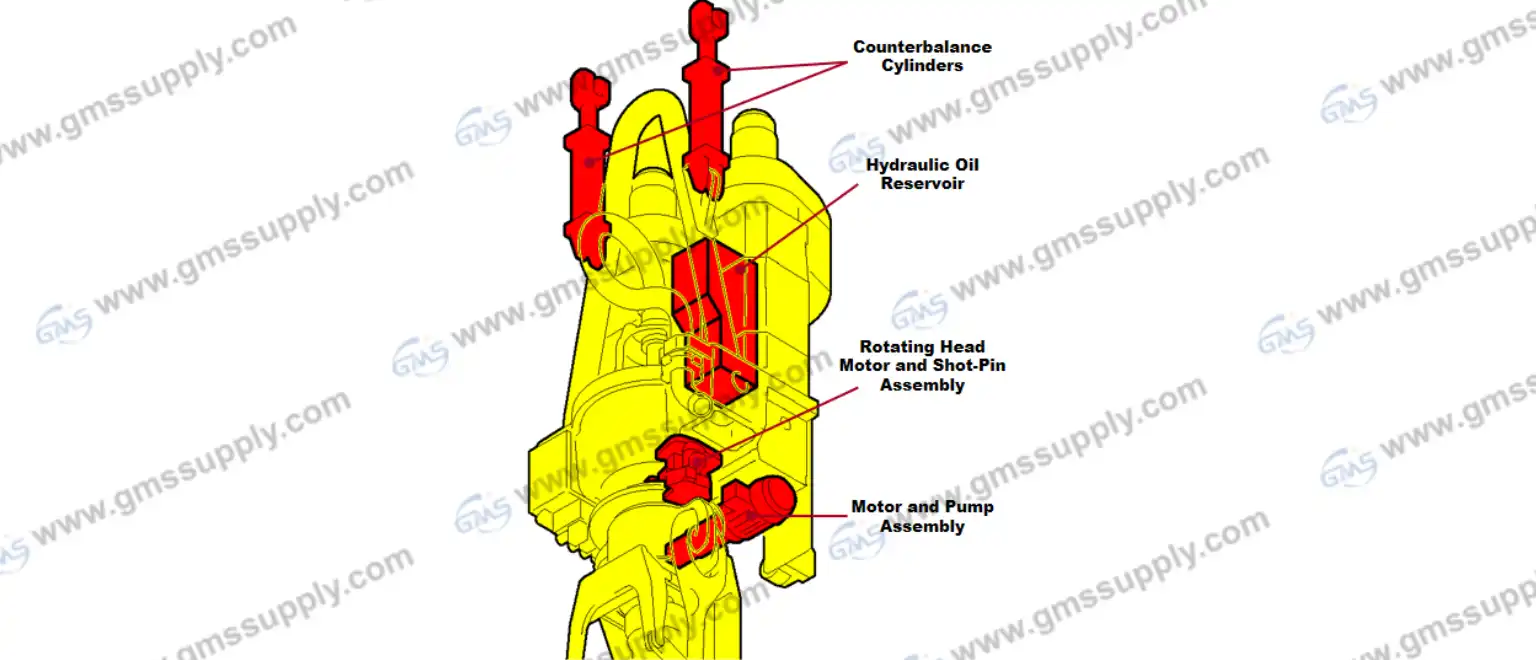

In the demanding world of oil and gas drilling operations, component reliability directly impacts operational efficiency and cost management. The 30151875 Shot Pin Assembly serves as a critical component within top drive systems, specifically designed for motor housing and transmission operations in TDS-11 and TDS-9SA models. This assembly must perform consistently under extreme drilling conditions, including high pressure environments, temperature fluctuations, and continuous mechanical stress. Understanding how this component maintains reliability in challenging operational scenarios is essential for drilling contractors, equipment maintenance teams, and procurement specialists who seek to optimize their drilling operations while managing costs effectively.

Understanding the Critical Role of Shot Pin Assemblies in Top Drive Operations

The 30151875 Shot Pin Assembly functions as an integral component within the motor housing and transmission system of top drive units. This precision-engineered assembly facilitates the engagement and disengagement mechanisms that control the power transmission between the hydraulic motor and the gearbox assembly. During drilling operations, the shot pin assembly experiences continuous cycling under substantial hydraulic pressure, typically operating within pressure ranges that can exceed several thousand PSI. The assembly must maintain precise alignment and sealing integrity to prevent hydraulic fluid contamination and ensure consistent power delivery to the drill string. In extreme conditions, such as offshore drilling platforms where environmental temperatures can range from minus forty-five degrees Celsius to plus fifty-five degrees Celsius, the shot pin assembly faces additional challenges including thermal expansion, material contraction, and potential corrosion from saltwater exposure. The component's reliability directly affects the top drive's ability to maintain continuous rotation speeds, which typically range from 180 to 600 revolutions per minute depending on the drilling application. When shot pin assemblies fail prematurely, operations experience costly downtime, potential damage to related transmission components, and increased maintenance requirements that can significantly impact project timelines and budgets.

Design Features That Enhance Performance Under Extreme Drilling Conditions

Modern shot pin assembly designs incorporate several engineering features specifically developed to withstand the harsh operational environments typical of drilling applications. The 30151875 Shot Pin Assembly utilizes advanced metallurgy in its construction, employing materials that resist wear under continuous friction and maintain structural integrity under variable temperature conditions. The sealing systems integrated within the assembly have evolved significantly, with contemporary designs featuring multiple sealing stages that prevent hydraulic fluid leakage even when components experience normal wear over extended operational periods. Recent improvements in shot pin assembly design address common failure modes identified through field experience, including excessive wear patterns that historically caused hydraulic fluid leaks and premature component degradation. The bearing assemblies within the shot pin mechanism utilize specialized materials and surface treatments that maintain low friction coefficients even in environments contaminated with drilling mud or other abrasive particles. Additionally, improved lubrication pathways ensure consistent fluid distribution to critical wear surfaces, extending operational intervals between maintenance requirements and reducing the frequency of complete assembly replacements.

Maintenance Strategies and Reliability Optimization for Extended Service Life

Implementing comprehensive maintenance protocols significantly extends shot pin assembly service life and reduces unexpected failures that disrupt drilling operations. Proactive inspection schedules should include regular monitoring of hydraulic fluid quality, checking for contamination indicators such as metal particles or water content that suggest internal component wear or seal degradation. Pressure testing of the shot pin hydraulic circuit identifies developing seal problems before they progress to catastrophic failures, allowing scheduled replacement during planned maintenance windows rather than emergency repairs during critical drilling phases. Visual inspection of external components during routine top drive servicing can reveal early warning signs including fluid seepage around seals, surface discoloration indicating excessive heat, or unusual wear patterns suggesting alignment issues within the assembly. Operators should maintain detailed service records documenting shot pin assembly operating hours, maintenance interventions, and any performance anomalies observed during drilling operations, as these records enable predictive maintenance approaches that schedule component replacement based on actual operational history rather than arbitrary time intervals. When replacement becomes necessary, selecting assemblies manufactured to rigorous quality standards ensures consistent performance and reduces the likelihood of premature failure. Components meeting international quality certifications demonstrate compliance with established manufacturing standards and provide greater assurance of dimensional accuracy, material specifications, and performance consistency across production batches.

Cost-Effective Alternatives: Aftermarket Solutions for Budget-Conscious Operations

While original equipment manufacturer components offer proven reliability, high-quality aftermarket alternatives provide significant cost advantages for drilling operations seeking to optimize maintenance budgets without compromising performance standards. The 30151875 Shot Pin Assembly aftermarket solutions manufactured by experienced suppliers deliver comparable performance to OEM parts while offering substantial price advantages that benefit companies managing multiple drilling rigs or executing extended drilling campaigns. These alternatives particularly suit non-critical replacement scenarios or operations where equipment downtime for component failure would not result in catastrophic project delays or safety concerns. Aftermarket components manufactured under ISO 9001 certified quality management systems demonstrate consistent production standards and reliable performance characteristics suitable for demanding drilling applications. The cost differential between OEM and aftermarket shot pin assemblies can reach substantial percentages of the original component price, allowing drilling contractors to maintain larger spare parts inventories for the same budget allocation, reducing equipment downtime by ensuring replacement components remain readily available when failures occur during remote operations. Additionally, aftermarket suppliers often maintain larger inventories with shorter lead times compared to OEM channels, enabling faster parts delivery that minimizes operational delays when emergency replacements become necessary.

Selecting the Right Supplier for Your Shot Pin Assembly Requirements

Choosing an appropriate supplier for shot pin assemblies requires careful evaluation of multiple factors beyond simple price comparisons. Experienced suppliers with established track records in the drilling equipment industry demonstrate understanding of operational requirements and quality standards specific to top drive applications. Supplier certification under international quality standards such as ISO 9001 provides objective evidence of systematic quality management practices that ensure consistent product quality across production batches. Responsive customer service capabilities prove essential when urgent replacement requirements arise, with suppliers offering rapid response times and technical support significantly reducing operational disruptions compared to vendors with limited communication infrastructure. Comprehensive product inventories enable suppliers to fulfill orders promptly without extended manufacturing delays, particularly important for drilling operations in remote locations where extended parts delivery times substantially increase downtime costs. After-sales service support including technical consultation, warranty coverage, and problem resolution assistance provides additional value beyond the initial component purchase, helping operations optimize assembly installation and troubleshoot any performance issues that emerge during service. Flexible solutions tailored to specific operational requirements demonstrate supplier commitment to customer success rather than simple transactional relationships, with experienced suppliers offering customized approaches addressing unique drilling environment challenges or budget constraints.

Conclusion

The 30151875 Shot Pin Assembly remains a critical component for maintaining top drive reliability in extreme drilling conditions, with proper selection and maintenance practices directly impacting operational efficiency and cost management. As a specialized manufacturer of high-quality aftermarket solutions, Global Machinery Supply Co., Ltd. offers cost-effective alternatives to OEM components without compromising performance standards. With over fifteen years of industry experience, ISO 9001 certification ensuring quality consistency, and comprehensive support including rapid response times and extensive inventory availability, GMS delivers reliable products that reduce operating costs while maintaining the performance standards required for demanding drilling applications. Whether you need China 30151875 Shot Pin Assembly factory direct pricing, seek a dependable China 30151875 Shot Pin Assembly supplier with proven track record, require a China 30151875 Shot Pin Assembly manufacturer with flexible solutions, or search for China 30151875 Shot Pin Assembly wholesale options with short lead times, GMS provides 30151875 Shot Pin Assembly for sale with competitive 30151875 Shot Pin Assembly price structures tailored to your budget requirements. Contact us at sales@gmssupply.com to discuss your specific drilling equipment needs and discover how our expertise can enhance your operational reliability while optimizing your maintenance budget.

References

1. Yenzer, M. and Johnson, R. (2009). "Advanced Gearbox Design for Enhanced Top Drive Reliability in Offshore Applications," Journal of Petroleum Technology, Vol. 61, Issue 10.

2. Thompson, K. (2024). "Maintenance Optimization Strategies for Top Drive Systems in Extreme Environmental Conditions," International Journal of Oil and Gas Engineering, Vol. 15, No. 3.

3. Rodriguez, P. and Chen, L. (2023). "Material Selection and Failure Analysis of Hydraulic Components in Top Drive Shot Pin Assemblies," Drilling Engineering Quarterly, Vol. 38, Issue 2.

4. Davidson, S. (2024). "Cost-Benefit Analysis of OEM versus Aftermarket Components in Drilling Operations," Energy Equipment Management Review, Vol. 22, No. 4.

5. Williams, J. and Kumar, A. (2025). "Performance Evaluation of Top Drive Components Under Variable Temperature and Pressure Conditions," Mechanical Systems in Petroleum Engineering, Vol. 44, Issue 1.

Learn about our latest products and discounts through SMS or email

_1754637884686.webp)