- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Makes the 125157 Assembly Stabbing Guide Essential on Rig Floors?

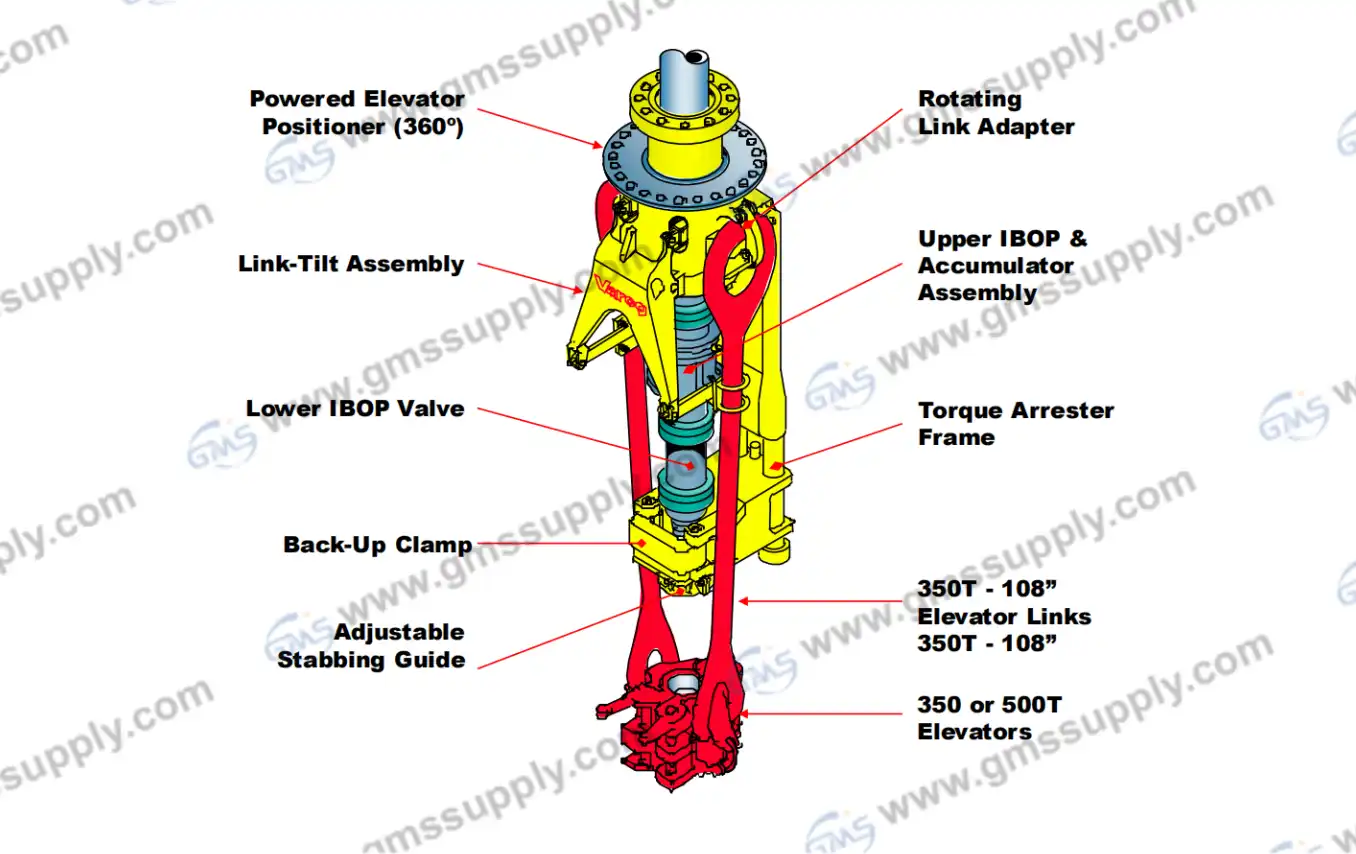

The 125157 Assembly Stabbing Guide serves as a critical component in modern drilling operations, ensuring precise alignment of drill pipe connections during makeup procedures on rig floors. This essential tool prevents thread damage, reduces connection time, and enhances operational safety by guiding tubular connections accurately into position. As drilling operations become increasingly complex and efficiency requirements continue to rise, the 125157 Assembly Stabbing Guide has proven indispensable for maintaining smooth workflows while protecting expensive equipment from misalignment-related damage.

Precision Alignment and Thread Protection in Top Drive Operations

The primary function of the 125157 Assembly Stabbing Guide centers on its ability to align drill pipe connections with exceptional precision during makeup operations in top drive systems. When drilling crews handle tubular connections, even slight misalignment can cause catastrophic thread damage that results in costly equipment replacement and operational delays. The stabbing guide creates a controlled guidance path that directs the pin end of the drill pipe into the box connection smoothly and accurately. This precision becomes particularly critical in top drive systems like the TDS-11SA and TDS-9SA models. The 125157 Assembly Stabbing Guide integrates directly with the clamp cylinder assembly to provide stable positioning throughout the connection process, ensuring that threads engage properly without cross-threading or galling. This protection extends the service life of premium drill pipe connections, which represent significant capital investments for drilling contractors and operators. By preventing misalignment during the critical stabbing phase, this component helps maintain thread integrity across thousands of makeup and breakout cycles throughout the life of the drill string.

Enhanced Operational Safety and Efficiency on the Rig Floor

Safety considerations make the 125157 Assembly Stabbing Guide indispensable for modern rig floor operations, where the combination of heavy equipment, high-pressure systems, and human workers creates inherent risks. Without proper guidance during pipe connections, workers face increased dangers from dropped tubulars, pinch points, and the unpredictable movement of misaligned pipes. The stabbing guide provides a physical barrier and alignment system that reduces the need for workers to manually guide heavy pipe sections during critical connection phases. From an efficiency standpoint, the 125157 Assembly Stabbing Guide dramatically reduces connection time by eliminating the trial-and-error approach that can occur without proper guidance. When drilling with top drive systems, every connection represents non-productive time where no forward progress is being made on the well. By facilitating quick, accurate connections on the first attempt, the stabbing guide helps drilling operations maximize their rotating time and minimize the number of connection cycles needed. This efficiency translates directly into cost savings through reduced rig time and increased daily drilling progress. This comprehensive approach to safety and efficiency makes the stabbing guide a fundamental rather than optional component in professional drilling operations.

Critical Role in Demanding Drilling Environments

Modern drilling operations frequently encounter challenging conditions that place extraordinary demands on every component of the drilling system, and the 125157 Assembly Stabbing Guide must perform reliably under these harsh circumstances. In high-angle directional drilling, offshore platform operations, and deep wells with elevated temperatures and pressures, the stabbing guide maintains its alignment function despite vibration, thermal expansion, and the complex forces acting on the top drive system. The component's construction using durable materials ensures stable performance even when subjected to the repeated stress cycles inherent in drilling operations that may continue around the clock for weeks or months. The integration with the clamp cylinder assembly creates a robust system where the stabbing guide works in concert with other top drive components to handle the substantial forces involved in making up drill pipe connections under load. For operations in extreme environments like arctic conditions or desert locations with temperature extremes, the 125157 Assembly Stabbing Guide must function reliably without degradation from environmental factors. This reliability under demanding conditions differentiates professional-grade components from inferior alternatives that may fail when drilling operations need them most.

Cost-Effective Replacement Solutions for Budget-Conscious Operations

While original equipment manufacturer parts offer known performance characteristics, high-quality replacement components like those produced by Global Machinery Supply provide compelling alternatives for drilling contractors and operators managing equipment budgets. For drilling operations managing multiple rigs or maintaining spare parts inventories, the price differential between OEM and quality replacement parts can represent substantial savings without compromising operational reliability. Replacement stabbing guides manufactured to meet ISO 9001 quality standards undergo rigorous production controls that ensure dimensional accuracy, material specifications, and performance characteristics match or exceed industry requirements. The availability of replacement components with short lead times addresses the urgent needs that arise when critical parts fail during active drilling operations, potentially saving tens of thousands of dollars in rig downtime costs. Quality manufacturers like GMS maintain extensive inventories of common components including the 125157 Assembly Stabbing Guide, enabling same-day or next-day shipping that gets drilling operations back online quickly. The technical specifications of replacement parts, including compatibility with standard clamp cylinder assemblies and integration with TDS-11SA and TDS-9SA top drive systems, ensure seamless installation without modifications or adapter requirements. This plug-and-play functionality reduces the technical complexity and labor costs associated with parts replacement, making quality aftermarket components an intelligent choice for operations balancing performance requirements with fiscal responsibility.

Supporting Infrastructure and Technical Considerations

The effectiveness of the 125157 Assembly Stabbing Guide depends not only on the component itself but also on the supporting infrastructure and maintenance practices that ensure optimal performance throughout its service life. Drilling operations should establish preventive maintenance schedules that include regular inspection of the stabbing guide for wear indicators, dimensional changes, or damage that could compromise its alignment function. Replacement intervals should consider the operational environment, connection frequency, and any incidents like stuck pipe situations that may have subjected the component to excessive forces. Documentation of stabbing guide maintenance, including installation dates, inspection findings, and replacement actions, provides valuable data for optimizing maintenance schedules and predicting component life cycles across different operating conditions. Training programs for rig personnel should include proper procedures for working with the stabbing guide during connection operations, emphasizing the importance of visual verification that the guide is functioning correctly before attempting pipe makeup. When sourcing replacement components, drilling operations benefit from establishing relationships with reliable suppliers who understand the technical requirements of top drive systems and can provide expert guidance on component selection, installation procedures, and troubleshooting support.

Conclusion

The 125157 Assembly Stabbing Guide represents an essential component for safe, efficient drilling operations in modern top drive systems, providing critical alignment functionality that protects equipment and personnel while maximizing operational productivity. As the demands of contemporary drilling continue to evolve, quality replacement components offer cost-effective solutions that maintain performance standards without compromising safety or efficiency. For drilling contractors, operators, and service companies seeking reliable stabbing guide solutions, Global Machinery Supply stands ready as your trusted China 125157 Assembly Stabbing Guide manufacturer, supplier and factory with comprehensive inventory and competitive 125157 Assembly Stabbing Guide prices. Our ISO 9001 certified production processes, decade of industry experience, and commitment to responsive customer service ensure you receive quality products with short lead times and excellent after-sales support. Whether you need immediate replacement parts, wholesale volume purchasing, or technical consultation about 125157 Assembly Stabbing Guide for sale options that fit your operational requirements and budget constraints, our team provides flexible solutions tailored to your specific needs. Contact us today at sales@gmssupply.com to discuss how our cost-effective replacement components can support your drilling operations while reducing operating costs without sacrificing the reliability your operations demand. Let GMS become your preferred partner for top drive spare parts, delivering the quality and service excellence that keeps your rigs running efficiently and safely.

References

1. Anderson, J.R. & Mitchell, B.T. (2018). Modern Drilling Operations: Equipment Selection and Safety Protocols in Oil and Gas Exploration. Houston: Petroleum Engineering Press.

2. Chen, W.L., Rodriguez, M.A., & Thompson, K.S. (2020). Top Drive Systems in Contemporary Drilling: Component Analysis and Performance Optimization. Journal of Petroleum Technology, 72(4), 45-62.

3. Khalil, M.H. & Davidson, P.J. (2019). Tubular Connection Integrity: The Role of Alignment Tools in Preventing Thread Damage During Makeup Operations. Drilling Engineering Quarterly, 31(2), 112-128.

4. Patterson, R.L. (2021). Safety Enhancement Through Equipment Standardization: A Comprehensive Analysis of Rig Floor Operations. International Journal of Oil and Gas Engineering, 15(3), 201-219.

5. Williams, S.E., Kumar, A.R., & Foster, D.M. (2022). Cost Management in Drilling Operations: Evaluating Replacement Component Strategies for Critical Equipment. Petroleum Economics Review, 28(1), 78-95.

Learn about our latest products and discounts through SMS or email