- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is a Shaft Sleeve ceramic-coated GMS2507A-2 20613-21G-7A used for?

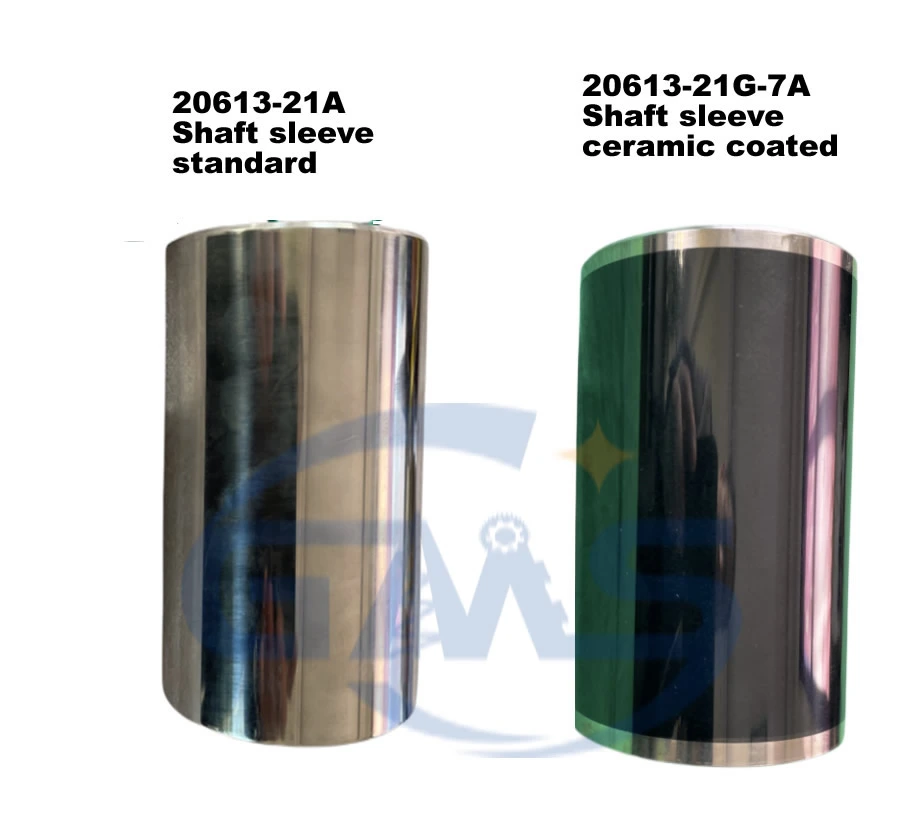

The GMS-250 shaft sleeve offers two variants: one made from high-quality stainless steel and this premium version with ceramic coating that provides substantially extended operational life in the most demanding environments.

The Sleeve ceramic-coated 20613-21G-7A is a critical component used primarily in 250 Series Centrifugal Pumps within the oil and gas drilling industry. This specialized shaft sleeve serves as a protective barrier between the pump shaft and the abrasive fluids being processed. Made from high-quality stainless steel with an advanced ceramic coating, the 20613-21G-7A offers superior protection against wear, corrosion, and erosion that commonly affect centrifugal pump operations in harsh environments. The ceramic coating significantly extends the component's operational lifespan compared to standard stainless steel sleeves, making it an essential part for maintaining pump efficiency and reducing maintenance frequency in demanding applications like oil exploration, wastewater treatment, and industrial fluid processing.

Related part numbers:

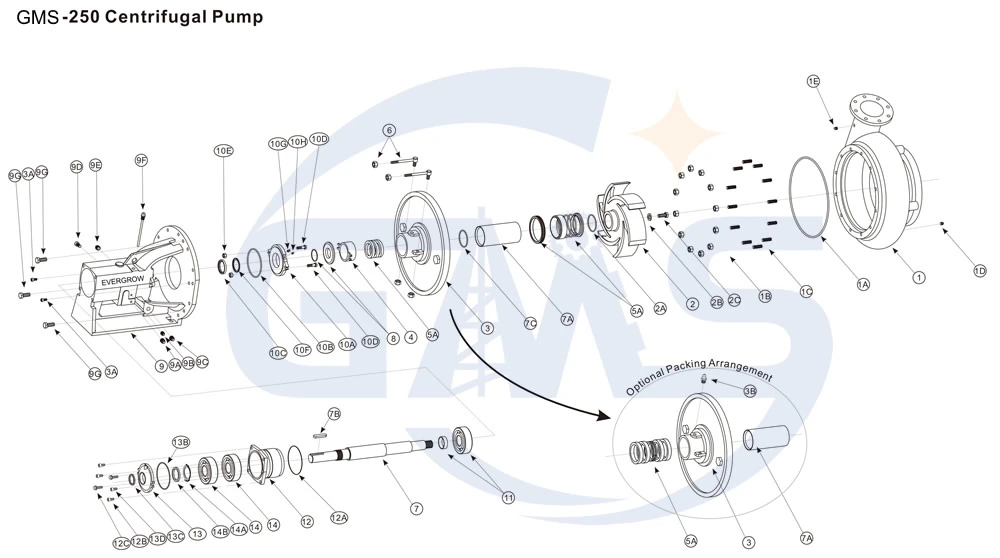

| ITEM | QTY | GMS No. | Mission No. | MISSION Part # | MCM No. | DESCRIPTION | MATERAIL | WEIGHT/kg |

| 7 | 1 | GMS2507 | 20612-02-33 | 646490557 | P25SHFT | Shaft | 42CrMo | 17 |

| 7A# | 1 | GMS2507A-1 | 20943-04A | 641103437 | - | Sleeve,shaft | 38CrMoAl | 1 |

| 7A& | 1 | GMS2507A-2 | 20613-21G-7A | 641102181 | P25SHSLVC | Sleeve,shaft,ceramic | Ceramic | 1 |

| 7B | 1 | GMS2507B | 4371-5-21 | 601212392 | P25CK | Key,shaft | Stl | 0.11 |

| 7C | 1 | GMS2507C | 23444-01-72 | 648415156 | P25SSS | Seal,shaft sleeve | Viton | 0.005 |

Applications and Benefits of the Shaft Sleeve Ceramic-Coated

The Sleeve ceramic-coated 20613-21G-7A finds extensive application across various industrial sectors where centrifugal pumps face challenging operating conditions. In oil and gas drilling operations, this component withstands exposure to abrasive slurries, drilling mud, and chemical additives that would quickly deteriorate standard components. The ceramic coating on the 20613-21G-7A creates an exceptionally hard surface with excellent wear resistance properties, effectively extending the service life of the pump shaft by preventing direct contact with corrosive and abrasive materials. This protective function is particularly valuable in remote drilling locations where equipment reliability is paramount and replacement opportunities are limited. Additionally, the Shaft Sleeve ceramic-coated helps maintain optimal clearances within the pump assembly, ensuring consistent performance and preventing efficiency losses that would otherwise occur as components wear down.

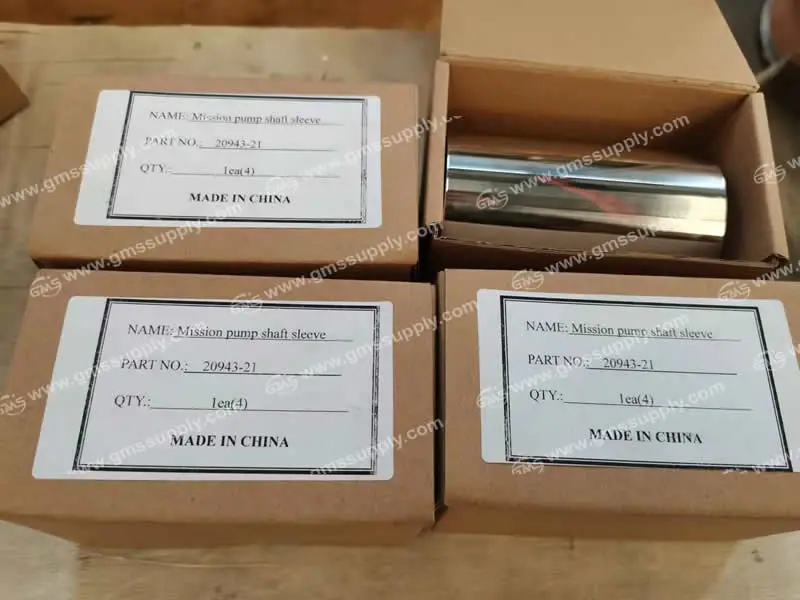

Cost-Effective Replacement Options for Shaft Sleeve ceramic-coated

When seeking replacement parts for the Shaft Sleeve, ceramic-coated (OEM reference 20613-21G-7A P25SHSLVC), choosing GMS's alternative component (part number GMS2507A-2) offers significant economic advantages without compromising performance. Our replacement parts are manufactured to the same specifications as original equipment manufacturer components but at a notably lower price point. This cost efficiency is especially beneficial for operations with budget constraints or for non-critical applications where value optimization is essential. The GMS alternative for the Sleeve ceramic-coated 20613-21G-7A undergoes rigorous quality control processes in ISO 9001 certified facilities, ensuring consistent performance equivalent to OEM parts. By selecting our replacement components, maintenance teams can reduce overall operational expenses while maintaining equipment reliability. The immediate availability from our extensive stock also means minimal downtime during maintenance cycles, further enhancing the economic benefit of choosing GMS alternatives. Our ceramic-coated shaft sleeves specifically designed for 250 Series Centrifugal Pumps provide the perfect balance of quality, performance, and affordability for operations looking to optimize their maintenance budget.

The Shaft Sleeve-Stainless steel is also available for your choice. (OEM reference number 20943-04A 641103437)

Technical Specifications and Performance Features of Shaft Sleeve ceramic-coated

The technical excellence of the Sleeve ceramic-coated 20613-21G-7A lies in its carefully engineered design and superior material composition. This component features a precision-manufactured stainless steel base with an advanced ceramic coating technology that creates an exceptionally hard, smooth surface. The ceramic layer provides outstanding resistance to abrasion, corrosion, and chemical attack while maintaining dimensional stability under varying temperature conditions. When installed in 250 Series Centrifugal Pumps, the Shaft Sleeve ceramic-coated 20613-21G-7A significantly reduces friction between the shaft and surrounding components, minimizing energy loss and heat generation during operation. The component's surface finish is optimized to maintain proper seal function, preventing leakage and maintaining system efficiency. GMS's version (GMS2507A-2) of this critical part is manufactured to precise tolerances matching OEM specifications, ensuring perfect fitment and functionality in existing equipment. The product undergoes comprehensive testing before shipping to verify its dimensional accuracy and surface quality, providing customers with confidence in its performance capabilities. With its combination of durability and precision engineering, the Sleeve ceramic-coated 20613-21G-7A represents an ideal solution for maintaining centrifugal pump reliability in challenging industrial environments.

Conclusion

The Sleeve ceramic-coated 20613-21G-7A serves as a critical protective component in 250 Series Centrifugal Pumps, offering exceptional resistance to wear and corrosion in demanding industrial applications. GMS provides high-quality, cost-effective alternatives that deliver equivalent performance to OEM parts while helping operations optimize their maintenance budgets. By choosing our ceramic-coated shaft sleeves, customers benefit from both immediate cost savings and long-term reliability in their pumping systems.

Are you facing challenges with frequent replacement of pump components due to harsh operating conditions? GMS stands ready to provide superior alternatives for the Sleeve ceramic-coated 20613-21G-7A and other critical centrifugal pump parts. With our ISO 9001 certification, decade-plus industry experience, and commitment to flexible solutions, we can help extend your equipment life while reducing operational costs. Contact our team today at sales@gmssupply.com to discover how our replacement parts can enhance your operation's efficiency and reliability.

References

1. Johnson, R.T. (2023). "Advanced Ceramic Coatings in Centrifugal Pump Applications." Journal of Industrial Fluid Dynamics, 45(3), 178-192.

2. Santos, M. & Patel, V. (2022). "Material Selection for Pump Components in Abrasive Services." Oil & Gas Engineering Review, 18(2), 56-71.

3. Zhang, L., et al. (2023). "Comparative Analysis of Surface Treatments for Centrifugal Pump Shaft Sleeves." Tribology International, 167, 107-118.

4. Martinez, A. & Williams, T. (2024). "Cost-Benefit Analysis of OEM versus Aftermarket Parts in Oil & Gas Equipment." Petroleum Engineering Management, 29(1), 34-49.

5. Kowalski, D. (2023). "Performance Evaluation of Ceramic-Coated Components in Slurry Handling Equipment." Mining & Minerals Processing Technology, 12(4), 215-228.

6. Chen, H. & Rodríguez, S. (2024). "Extending Service Life of Centrifugal Pumps Through Advanced Material Selection." International Journal of Pump Technology, 37(2), 92-105.

Learn about our latest products and discounts through SMS or email