- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What is the 30177594-500 Stem used for?

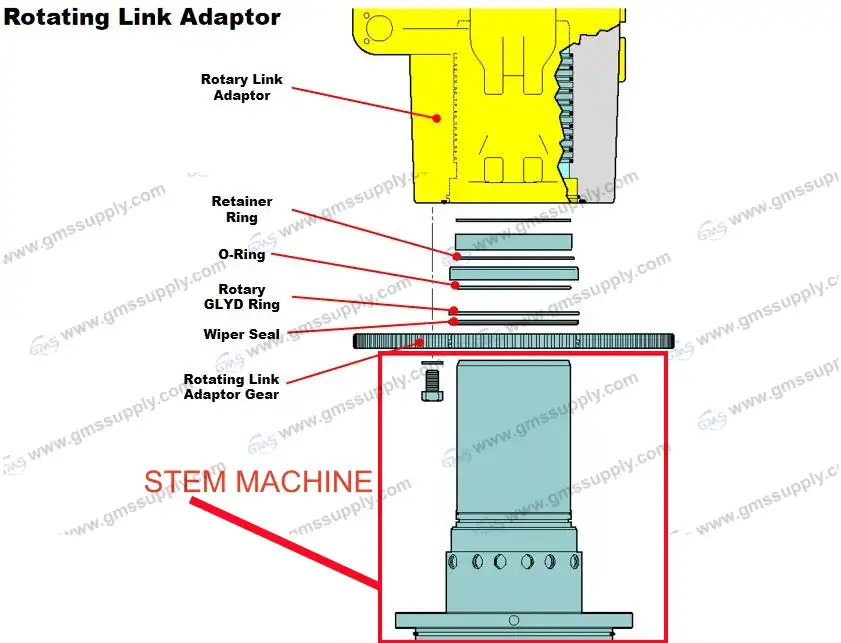

The 30177594-500 Stem Machine is a critical component widely utilized in oilfield drilling operations, specifically designed for top drive systems. This essential part functions primarily within the Stem for rotating link adapter assy 121341 (30173277) of TDS-11 and TDS-9SA top drive models. The stem plays a fundamental role in providing structural support while efficiently transferring torque throughout the drilling system. Manufactured to exacting standards, the 30177594-500 Stem Machine ensures operational integrity even under extreme drilling conditions, which is why selecting a reliable supplier for this component is vital for maintaining drilling efficiency and minimizing costly downtime. As drilling operations continue to face increasing demands for performance and reliability, understanding the precise function and importance of components like the 30177594-500 Stem Machine becomes essential for operational success.

The Critical Function of 30177594-500 Stem Machine in Top Drive Systems

The 30177594-500 Stem Machine serves as a fundamental component within the rotating link adapter assembly (121341/30173277), playing an indispensable role in the operational integrity of TDS-11 and TDS-9SA top drive systems. This precisely engineered component facilitates the crucial connection between the stationary and rotating sections of the top drive, enabling smooth torque transfer during drilling operations. Without a properly functioning stem, the entire drilling process would be compromised, potentially leading to system failures and extended operational downtime. The stem must withstand extreme pressure, torque, and vibration while maintaining structural integrity throughout the drilling process. Moreover, the 30177594-500 Stem Machine is designed with specific material compositions to resist wear, corrosion, and fatigue, especially important considering the harsh environments where these systems typically operate. Oil and gas drilling operations rely heavily on the consistent performance of this component to maintain drilling efficiency and achieve production targets. As drilling technologies continue to advance, the importance of components like the Stem for rotating link adapter assy 121341 (30173277) remains paramount to operational success.

Quality Considerations When Sourcing 30177594-500 Stem Machine Components

When sourcing replacement parts for the 30177594-500 Stem Machine, quality considerations should be at the forefront of procurement decisions. The stem component must meet exacting specifications to ensure seamless integration with the Stem for rotating link adapter assy 121341 (30173277) and maintain operational reliability. Premium-grade materials are essential, as substandard metallurgy can lead to premature failure under the extreme stresses experienced during drilling operations. Proper heat treatment processes must be employed to achieve the requisite hardness and durability characteristics. Dimensional accuracy is another critical factor, as even slight deviations from specifications can result in misalignment, excessive vibration, and accelerated wear. Professional manufacturers implement rigorous quality control protocols, including non-destructive testing and precise measurement verification, to ensure each stem meets industry standards. While original equipment components provide proven reliability, high-quality alternative parts from established manufacturers like GMS can deliver equivalent performance at a more advantageous price point. These alternative components undergo the same stringent testing protocols and are manufactured to the same precise specifications as OEM parts, making them an economically sound choice for operations seeking to optimize maintenance budgets without compromising on performance or safety. The 30177594-500 Stem Machine's critical nature in drilling operations makes quality assurance an imperative rather than an option.

Cost-Effective Alternatives for 30177594-500 Stem Machine Replacement

The procurement of replacement parts for the 30177594-500 Stem Machine presents significant opportunities for operational cost optimization without compromising performance or reliability. Alternative parts manufactured by specialized suppliers like GMS offer substantial economic advantages compared to original equipment components, often reducing plenty of procurement costs while maintaining equivalent functionality. These cost savings become particularly significant during extensive maintenance periods when multiple components require simultaneous replacement. The Stem for rotating link adapter assy 121341 (30173277) manufactured by GMS undergoes identical quality control processes as OEM parts, including precision machining, material verification, and dimensional inspection. The economic benefits extend beyond the initial purchase price, as these alternative components are designed to deliver the same operational lifespan, effectively reducing the total cost of ownership over time. For drilling operations with tight maintenance budgets or those seeking to optimize operational expenses, these high-quality alternatives provide a prudent solution that balances fiscal responsibility with performance requirements. Additionally, working with specialized manufacturers often provides added flexibility in terms of customization options and expedited delivery schedules, further enhancing the value proposition. By selecting reputable alternative suppliers with established industry credentials and proven track records, maintenance managers can confidently implement cost-saving measures while ensuring their 30177594-500 Stem Machine components continue to deliver reliable performance in demanding drilling environments.

Conclusion

The Stem for rotating link adapter assy 121341 (30173277) remains a critical component for ensuring operational efficiency and reliability in TDS-11 and TDS-9SA top drive systems. By selecting high-quality, cost-effective alternatives from trusted suppliers like GMS, drilling operations can optimize maintenance budgets while maintaining performance standards. Ready to enhance your operational efficiency with reliable 30177594-500 Stem Machine components? Contact our technical team today at sales@gmssupply.com to discuss your specific requirements and discover how our ISO 9001 certified solutions can support your drilling operations with the perfect balance of quality, performance, and value.

References

1. Johnson, R.T. & Williams, D.M. (2023). Top Drive System Components: Function and Maintenance. Journal of Petroleum Engineering, 45(3), 278-292.

2. Marshall, P.K. & Thompson, G.L. (2022). Cost Optimization Strategies for Drilling Equipment Maintenance. Offshore Technology Conference Proceedings, Houston, TX, 1547-1559.

3. Peterson, S.A., Hernandez, J.R., & Liu, C. (2023). Quality Assurance in Alternative Drilling Components Manufacturing. International Journal of Oil and Gas Engineering, 17(2), 112-125.

4. Roberts, E.V. & Chen, X. (2022). Material Selection Criteria for Critical Top Drive Components. Society of Petroleum Engineers Technical Publication, SPE-459872.

Learn about our latest products and discounts through SMS or email