- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

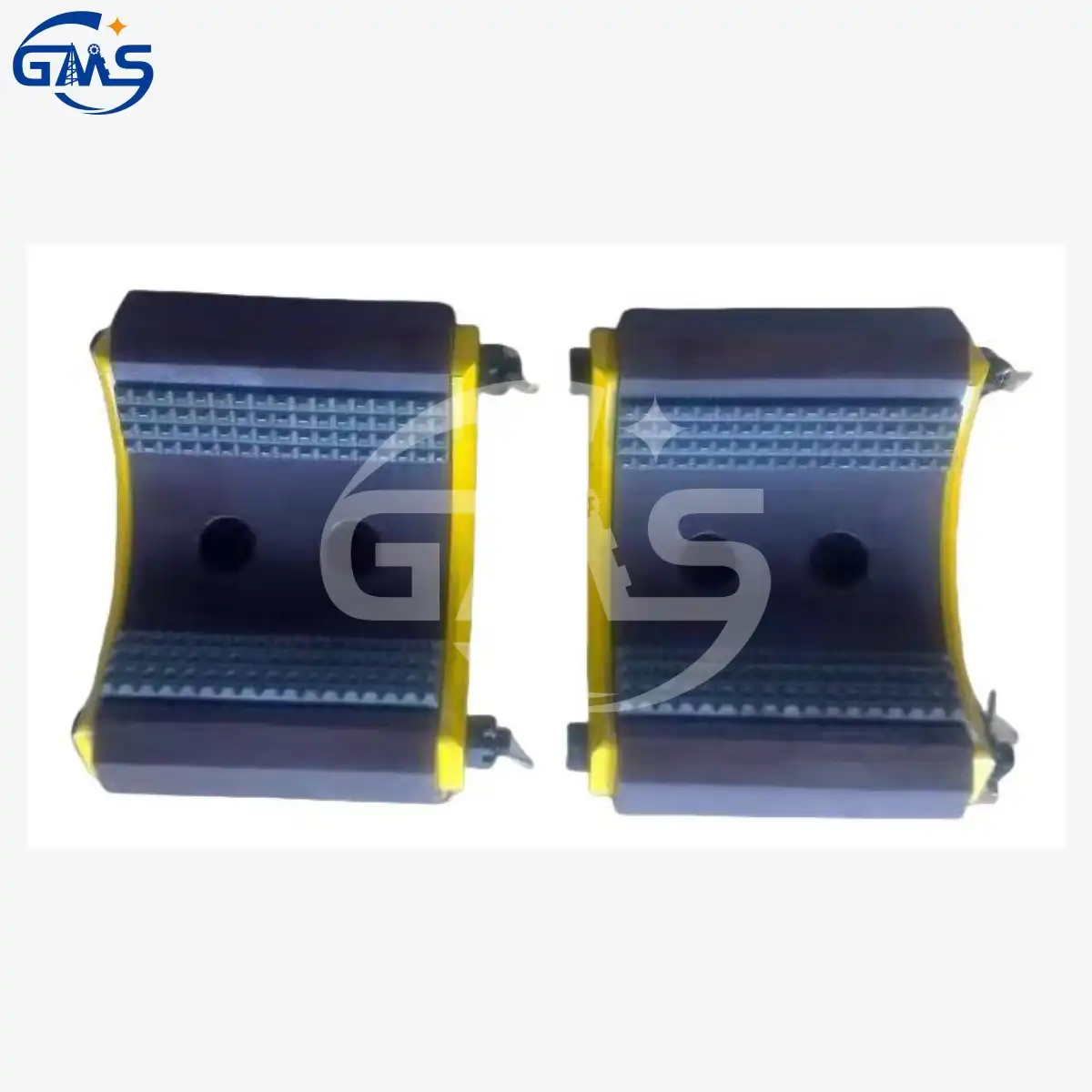

What is the DT12642 Cylinder Link Tilt?

The DT12642 Cylinder Link Tilt is a critical component in modern oilfield top drive systems, particularly in Canrig TDS system. This precision-engineered hydraulic cylinder is designed specifically for tilting operations, allowing for controlled movement of the top drive during drilling operations. The cylinder can automatically return to its neutral position after tilting, ensuring optimal positioning and operational stability. As a vital component in the top drive system, the DT12642 Cylinder Link Tilt plays an essential role in maintaining drilling efficiency, enhancing operational safety, and ensuring the smooth functioning of the entire drilling mechanism in challenging oilfield environments.

Function and Design of the DT12642 Cylinder Link Tilt

The DT12642 Cylinder Link Tilt features a sophisticated design tailored explicitly for the demanding requirements of oilfield drilling operations. At its core, this component serves as a hydraulic actuator that enables precise tilting movements of the top drive system, which is essential for proper alignment during drilling processes. The cylinder incorporates robust materials and precision engineering to withstand extreme environments typically encountered in drilling operations. The DT12642 Cylinder Link Tilt is engineered with specialized sealing systems to prevent hydraulic fluid leakage and maintain consistent performance even under strenuous operating conditions. Its self-centering mechanism allows for automatic return to the neutral position after completion of the tilting operation, ensuring proper positioning without operator intervention. The component's integration with the Canrig TDS system provides seamless operation and compatibility with existing top drive infrastructures. Furthermore, the design incorporates safety features that protect against sudden pressure changes and mechanical stresses. This thoughtful engineering ensures that the DT12642 Cylinder Link Tilt delivers reliable performance throughout its operational lifespan, minimizing downtime and maintenance requirements. The precision of its movement capabilities directly impacts drilling accuracy, making it an indispensable component for operations that demand high standards of performance and reliability.

Importance of Quality DT12642 Cylinder Link Tilt Replacements

When it comes to maintaining optimal drilling operations, the quality of replacement parts for the DT12642 Cylinder Link Tilt cannot be overstated. High-quality replacements ensure continued operational efficiency and prevent costly downtime that could result from component failure. While original equipment manufacturer (OEM) parts provide reliable performance, aftermarket alternatives from reputable suppliers like GMS offer significant advantages, particularly in terms of cost-effectiveness without compromising on quality and functionality. The DT12642 Cylinder Link Tilt operates in challenging conditions where failure is not an option. Quality aftermarket replacements from established manufacturers undergo rigorous testing and adhere to strict industry standards, ensuring they meet or exceed OEM specifications. GMS's replacement parts for the DT12642 Cylinder Link Tilt systems, including the DT12642 Cylinder Link Tilt, are manufactured with precision engineering and high-grade materials that withstand the harsh environments of drilling operations. Additionally, having a reliable supplier for these crucial components means faster access to parts when needed, reducing operational downtime and maintaining productivity. With over a decade of experience in providing top drive components, GMS ensures each DT12642 Cylinder Link Tilt replacement part meets the exacting standards required by the industry while offering significant cost savings compared to OEM alternatives. This balance of quality, reliability, and affordability makes GMS's replacement parts an intelligent choice for drilling operators looking to optimize their maintenance budgets without compromising safety or performance.

Maintenance and Installation Considerations for the DT12642 Cylinder Link Tilt

Proper maintenance and installation of the DT12642 Cylinder Link Tilt are essential for ensuring optimal performance and longevity of this critical component. Regular inspection protocols should include checking for hydraulic fluid leaks, examining mounting points for wear or damage, and verifying the smooth operation of the tilting mechanism. These preventative measures can significantly extend the service life of the component and help identify potential issues before they lead to system failure or costly downtime. When installing a replacement DT12642 Cylinder Link Tilt, technicians should follow manufacturer specifications for torque settings and alignment procedures. Proper installation is crucial for the Canrig TDS cylinder DT12642 system to function correctly, as misalignment can lead to uneven wear, reduced operational efficiency, and potentially catastrophic failure during critical drilling operations. Before installation, it's advisable to thoroughly flush the hydraulic system to remove any contaminants that could damage the new component. The DT12642 Cylinder Link Tilt requires specific hydraulic fluid types and operating pressures to perform optimally. Technicians should always refer to the technical specifications provided by GMS to ensure compatibility with existing systems. Additionally, after installation, a comprehensive testing procedure should be implemented to verify proper functioning under both no-load and operational conditions. This testing should include multiple tilting cycles to ensure smooth movement and proper return to neutral position. Implementing a scheduled maintenance program specifically for the DT12642 Cylinder Link Tilt and related components can prevent unexpected failures and extend the operational life of the entire top drive system. GMS provides guidelines and support to ensure that customers can maximize the value and performance of their replacement components.

Conclusion

The DT12642 Cylinder Link Tilt stands as a pivotal component in Canrig Top Drive System, enabling precise tilting operations crucial for drilling efficiency and safety. By choosing high-quality replacement parts from GMS, drilling operators can maintain optimal performance while significantly reducing maintenance costs. Our ISO 9001 certified products deliver the reliability and durability demanded by challenging oilfield environments without the premium price tag of OEM components. Ready to optimize your drilling operations with cost-effective, high-quality DT12642 Cylinder Link Tilt replacements? Contact our team at sales@gmssupply.com to discuss your specific requirements and discover how our decade of industry expertise can support your operational success. With GMS, you're not just buying a part—you're investing in a partnership focused on your long-term productivity and profitability.

References

1. Johnson, R. M. (2023). "Hydraulic Systems in Modern Top Drive Technology: Components and Maintenance." Journal of Petroleum Engineering, 45(3), 128-142.

2. Thompson, L. K., & Davis, A. P. (2022). "Critical Components in Canrig Top Drive Systems: Analysis and Performance Evaluation." International Journal of Drilling Engineering, 17(2), 87-103.

3. Martinez, S. R., Wilson, J. H., & Zhang, Q. (2023). "Comparative Study of OEM vs. Aftermarket Parts in Oilfield Equipment: Cost-Benefit Analysis." Oil & Gas Equipment Review, 31(4), 215-229.

4. Anderson, P. T., & Chen, L. (2024). "Preventative Maintenance Strategies for Hydraulic Cylinders in Top Drive Systems." Journal of Drilling Technology, 28(1), 56-72.

Learn about our latest products and discounts through SMS or email