- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

What Problems Does H04-1012-010 FLOW DIVIDER Solve?

In the demanding environment of oil and gas drilling operations, maintaining consistent hydraulic power distribution is critical for operational efficiency and equipment longevity. The H04-1012-010 FLOW DIVIDER addresses fundamental challenges in top drive systems by ensuring balanced hydraulic fluid distribution across multiple circuits while maintaining controlled flow rates and pressure levels. This hydraulic component plays a vital role in preventing uneven actuator movement, managing system pressure to avoid component overload, and synchronizing operations where multiple hydraulic motors or cylinders must work in tandem. Understanding these solutions helps drilling operators make informed decisions about equipment maintenance and replacement strategies.

Solving Uneven Hydraulic Power Distribution in Top Drive Systems

One of the most significant problems that the H04-1012-010 FLOW DIVIDER solves is uneven hydraulic power distribution in Canrig Top Drive systems, including models 8050, 8035, and 1250. When hydraulic fluid flows through a single source to multiple actuators without proper flow division, pressure differentials can cause some components to receive inadequate power while others experience excessive load. This imbalance leads to inconsistent performance, premature wear, and potential system failures that result in costly downtime. The flow divider component utilizes precision-engineered internal mechanisms to split incoming hydraulic flow into multiple controlled paths, ensuring that each actuator receives the appropriate amount of fluid regardless of varying load conditions across different circuits. This balanced distribution is particularly crucial in drilling operations where top drive motors must maintain synchronized rotation speeds and torque output to prevent drill string damage and ensure efficient hole advancement. Without this critical component functioning properly, operators may experience erratic top drive behavior, reduced drilling efficiency, and increased maintenance requirements that significantly impact operational costs and project timelines.

Preventing Component Overload Through Pressure Management

The H04-1012-010 FLOW DIVIDER incorporates sophisticated pressure management capabilities that protect expensive top drive components from overload conditions that could cause catastrophic failures. In hydraulic systems operating under the extreme conditions typical of oil and gas drilling, pressure spikes and uncontrolled flow surges can damage pumps, motors, cylinders, and seals, leading to unexpected breakdowns and safety hazards. This flow divider acts as a safeguard by maintaining controlled pressure levels across all output circuits, effectively distributing hydraulic loads to prevent any single component from experiencing damaging stress concentrations. The component's design allows it to absorb pressure differentials between circuits while maintaining stable flow rates, which is essential when drilling operations encounter varying formation resistance or when multiple hydraulic functions are activated simultaneously. During high-demand scenarios such as making connections, drilling through hard rock formations, or managing well control situations, the flow divider ensures that hydraulic pressure remains within safe operating parameters for all connected equipment. This protective function extends the service life of costly top drive components, reduces the frequency of unplanned maintenance interventions, and enhances overall drilling rig reliability.

Ensuring Synchronization in Multi-Actuator Applications

Synchronization challenges in hydraulic systems with multiple actuators represent a critical operational concern that the H04-1012-010 FLOW DIVIDER effectively addresses. In top drive applications where several hydraulic motors or cylinders must operate in coordinated fashion, even minor variations in flow rates can cause these components to fall out of synchronization, resulting in mechanical binding, uneven wear patterns, and potential equipment damage. The flow divider provides precise flow allocation to each actuator regardless of individual load variations, ensuring that all components move at consistent speeds and maintain proper timing throughout operational cycles. This synchronization capability is particularly valuable in top drive systems where rotational consistency directly affects drilling performance, hole quality, and drill string integrity. When multiple hydraulic circuits within the top drive system receive properly divided and balanced flow, the entire assembly operates more smoothly, with reduced vibration, lower noise levels, and improved energy efficiency. The component's ability to maintain synchronization under varying operational conditions prevents the cumulative positioning errors that can develop over multiple drilling cycles, which if left uncorrected, may require system shutdown for manual repositioning or adjustment. For drilling contractors and operators working in challenging environments where equipment reliability is paramount, a properly functioning flow divider serves as essential insurance against synchronization-related failures that could compromise drilling operations and project economics.

Reducing Maintenance Costs and Operational Downtime

Beyond its primary hydraulic functions, the H04-1012-010 FLOW DIVIDER contributes significantly to reducing overall maintenance expenses and minimizing unplanned operational downtime in drilling operations. When this component functions correctly, it prevents the cascading failures that often occur when hydraulic imbalances go uncorrected, where initial problems with flow distribution lead to accelerated wear on pumps, motors, and seals throughout the system. By maintaining balanced hydraulic conditions, the flow divider extends the operational intervals between major maintenance events, allowing drilling operations to continue with fewer interruptions for component replacement or system overhauls. The availability of cost-effective replacement components from experienced suppliers like Global Machinery Supply Co., Ltd. provides additional economic advantages, enabling operators to maintain system performance without the premium costs associated with original equipment manufacturer parts. Quality replacement flow dividers manufactured to ISO 9001 standards offer equivalent performance characteristics while delivering substantial cost savings, making them particularly attractive for budget-conscious operators or for non-critical component replacement scenarios where price advantages can be realized without compromising operational reliability. Drilling contractors who stock these replacement components benefit from faster turnaround times when maintenance is required, as the short lead times and readily available inventory eliminate the extended waiting periods that can keep drilling rigs idle while awaiting parts delivery. This combination of reduced failure rates due to proper hydraulic balance and the economic advantages of quality replacement components creates a compelling value proposition for operators seeking to optimize their maintenance strategies and control operational expenses in an increasingly competitive drilling services market.

GMS Quality Alternative Flow Dividers: Reliable Performance at Competitive Prices

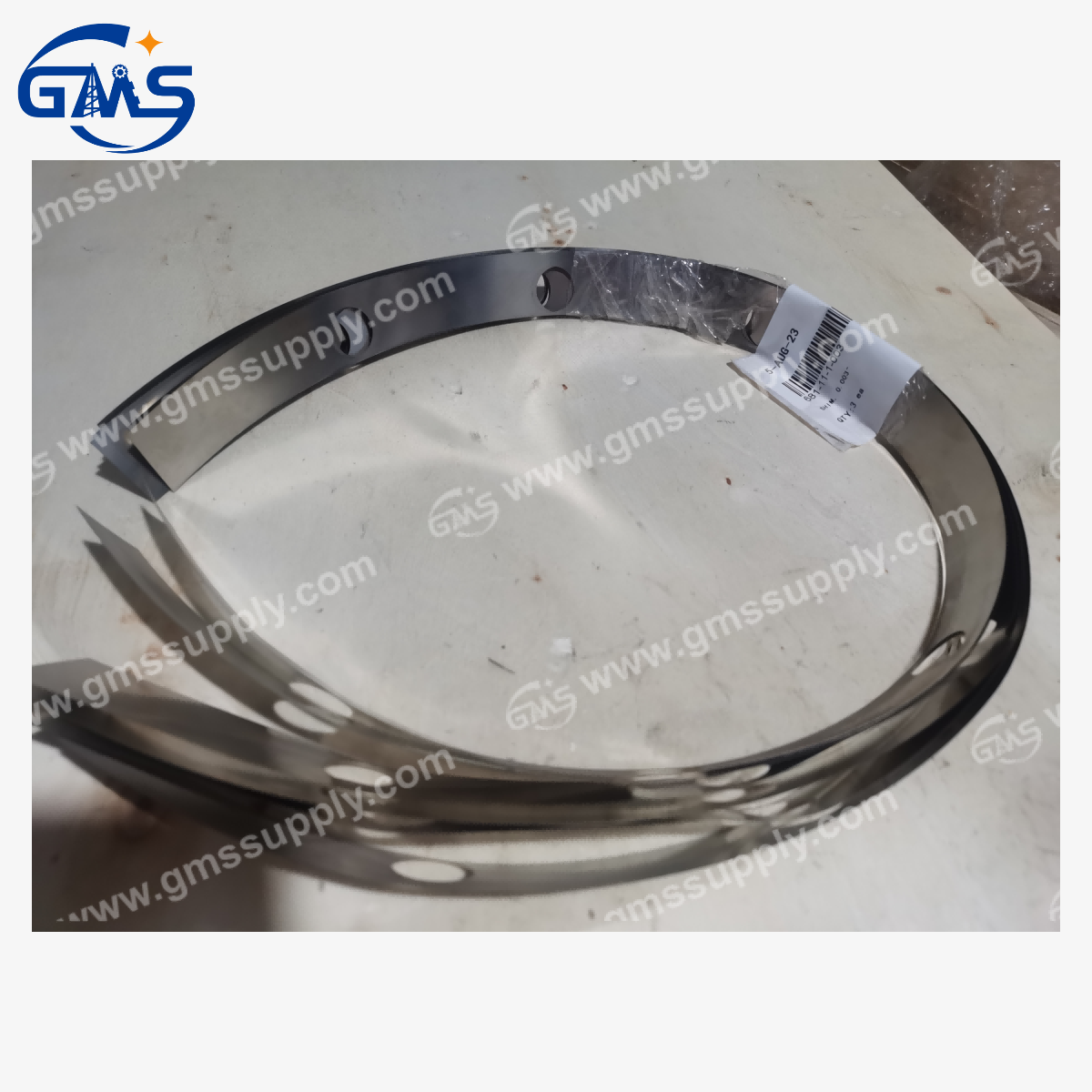

Global Machinery Supply Co., Ltd. specializes in providing high-quality replacement hydraulic components for drilling equipment, with the H04-1012-010 FLOW DIVIDER representing a prime example of their commitment to delivering reliable solutions at competitive price points. With over a decade of experience serving the oil and gas exploration industry, GMS has established itself as a trusted supplier of top drive spare parts for Canrig systems, offering products that meet the same performance standards as original equipment while providing significant cost advantages. The company's flow divider replacement, identified as part number C80350393, is manufactured in China under strict ISO 9001 quality management systems that ensure consistent product quality and performance characteristics. GMS maintains extensive inventory of this and other critical top drive components, enabling them to provide stock availability or very short lead times that keep drilling operations moving forward without extended delays. Their technical team understands the importance of product reliability in drilling applications and works closely with customers to ensure proper component selection and application support. For drilling contractors, equipment distributors, and engineering procurement companies seeking to optimize their spare parts strategies, GMS offers a compelling alternative that balances quality, availability, and cost-effectiveness in a single supplier relationship.

Conclusion

The H04-1012-010 FLOW DIVIDER solves critical hydraulic distribution challenges in top drive systems by ensuring balanced power delivery, preventing component overload, and maintaining synchronization across multiple actuators. These capabilities directly translate into improved drilling efficiency, reduced maintenance costs, and enhanced equipment reliability for operators in the oil and gas industry. Quality replacement components from GMS provide an economical solution for maintaining system performance while managing operational budgets effectively.

Ready to optimize your top drive system performance with reliable, cost-effective hydraulic components? As a leading China H04-1012-010 FLOW DIVIDER manufacturer, supplier and factory, Global Machinery Supply Co., Ltd. offers premium H04-1012-010 FLOW DIVIDER for sale at competitive H04-1012-010 FLOW DIVIDER price points. Our extensive experience in drilling machinery supply, combined with ISO 9001 certification and comprehensive inventory, ensures you receive quality products with fast delivery and excellent after-sales support. Contact us today at sales@gmssupply.com for a detailed quotation and discover how our flexible solutions can meet your unique operational requirements. We also offer China H04-1012-010 FLOW DIVIDER wholesale options for distributors and large-scale operations. Partner with GMS and experience the difference that quality, reliability, and customer-focused service can make in your drilling operations.

References

1. Watton, J., "Fluid Power Systems: Modeling, Simulation, Analog and Microcomputer Control," Prentice Hall International Series in Systems and Control Engineering, examining hydraulic flow control mechanisms and pressure management in industrial applications.

2. Anderson, W.R., "Hydraulic System Design and Analysis for Mobile Equipment," Society of Automotive Engineers Technical Paper Series, discussing synchronized actuator control in heavy machinery.

3. Merritt, H.E., "Hydraulic Control Systems," John Wiley & Sons, covering fundamental principles of flow division and distribution in multi-circuit hydraulic systems.

4. Esposito, A., "Fluid Power with Applications," Pearson Education, analyzing flow divider circuits and their role in preventing component overload in hydraulic systems.

5. Mitchell, R.F. and Miska, S.Z., "Fundamentals of Drilling Engineering," Society of Petroleum Engineers Textbook Series, addressing hydraulic systems in drilling rig top drive applications.

Learn about our latest products and discounts through SMS or email