- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

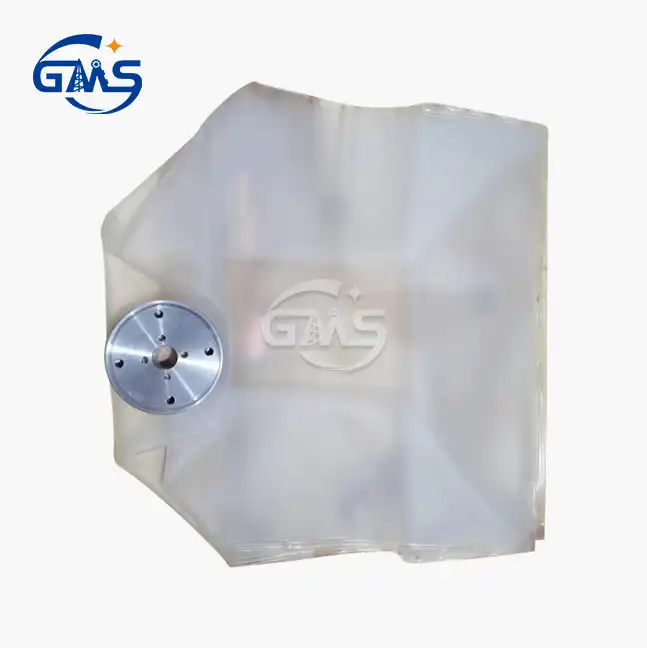

Application Guide for 110562-1 Accumulator Hydro Pneumatic 6 inch

The 110562-1 Accumulator Hydro Pneumatic 6 inch serves as a critical component within hydraulic systems used throughout the oil and gas drilling industry, particularly in top drive operations. This comprehensive application guide explores the essential functions, technical specifications, and practical implementation considerations for this accumulator model. Understanding the proper application of the 110562-1 Accumulator Hydro Pneumatic 6 inch enables drilling contractors, equipment operators, and maintenance personnel to optimize system performance, enhance operational safety, and maximize equipment longevity in demanding drilling environments.

Understanding Hydro-Pneumatic Accumulator Technology in Drilling Operations

Hydro-pneumatic accumulators represent sophisticated energy storage devices that utilize compressed nitrogen gas to maintain hydraulic pressure within drilling rig systems. The 110562-1 Accumulator Hydro Pneumatic 6 inch specifically employs a bladder or diaphragm design that separates the nitrogen charge from the hydraulic fluid, preventing contamination while enabling efficient energy transfer. Within top drive hydraulic packages, these accumulators perform multiple critical functions including pressure stabilization, shock absorption, and emergency power backup. The technology relies on the principle that nitrogen gas can be compressed to store potential energy, which is then released on demand to supplement hydraulic pump output during peak load conditions. In drilling operations, where hydraulic systems must respond instantly to changing torque requirements and mechanical stresses, the accumulator acts as a buffer that smooths out pressure fluctuations and prevents system damage. The six-inch diameter specification of the 110562-1 model indicates its volumetric capacity and flow characteristics, making it particularly well-suited for mid-range hydraulic packages commonly found in TDS-11SA and TDS-9SA top drive systems. The accumulator's construction typically features high-strength steel shells capable of withstanding pressures exceeding 3,000 psi, with specialized sealing materials designed to maintain gas-tight integrity throughout extended operational cycles. Understanding these fundamental operating principles helps maintenance teams diagnose performance issues, optimize precharge pressures, and implement proper preventive maintenance protocols that extend component service life.

Replacement Parts Advantages and Cost Efficiency

When evaluating options for accumulator replacement or system upgrades, replacement parts manufactured to original equipment specifications offer compelling advantages that merit serious consideration. The 110562-1 Accumulator Hydro Pneumatic 6 inch replacement components provide identical functional performance compared to original parts while delivering significant cost savings that positively impact operational budgets. These cost advantages become particularly meaningful for drilling contractors managing multiple rigs or for operations replacing non-critical accumulators where budget constraints influence procurement decisions. Replacement accumulators manufactured by specialized suppliers like Global Machinery Supply incorporate the same engineering principles, material specifications, and quality control processes that ensure reliable performance equal to original components. The manufacturing process utilizes high-grade steel shells, certified elastomer bladders, and precision-machined valve assemblies that meet international quality standards including ISO 9001 certification requirements. Price advantages typically range from twenty to forty percent compared to original equipment manufacturer pricing, representing substantial savings especially when multiple units require replacement during major overhaul activities. Beyond initial purchase price, replacement parts offer additional economic benefits through shorter lead times that minimize equipment downtime during planned maintenance windows. While original manufacturer parts may require extended ordering periods spanning several weeks or months, quality replacement suppliers maintain ready inventory that enables delivery within days of order placement. This inventory availability becomes crucial during unplanned maintenance events when every day of rig downtime represents significant revenue loss and contractual penalty exposure. The combination of cost savings, equivalent performance specifications, and superior availability makes replacement accumulators an intelligent choice for budget-conscious operators who refuse to compromise on equipment reliability or operational safety. Procurement strategies that incorporate approved replacement suppliers as standard practice enable drilling contractors to reduce total cost of ownership while maintaining the high performance standards demanded by modern drilling operations.

Installation and Maintenance Best Practices

Proper installation and ongoing maintenance of the 110562-1 Accumulator Hydro Pneumatic 6 inch directly influences system reliability and accumulator service life. Installation begins with thorough inspection of the hydraulic manifold mounting location, verifying that all port threads are clean, undamaged, and properly sized for the accumulator connections. The accumulator must be installed vertically or at a slight angle with the gas valve positioned at the highest point, preventing hydraulic fluid from entering the gas side and ensuring the bladder seats correctly within the shell. Before connection to the hydraulic system, technicians should verify that the nitrogen precharge pressure matches system requirements, typically accomplished using specialized accumulator charging equipment that connects to the gas valve. Hydraulic connections require appropriate thread sealant or O-rings specified by the manufacturer, with proper torque values applied to prevent leakage while avoiding over-tightening that could damage fittings. Following installation, the system should be pressurized gradually while monitoring for external leaks around all connections, with particular attention paid to the gas valve stem and hydraulic port interfaces. Initial operation should include verification that system pressure responds appropriately to pump activation and that the accumulator charges and discharges according to expected performance parameters. Ongoing maintenance begins with regular visual inspections checking for external corrosion, mechanical damage, or fluid seepage that could indicate developing problems. Precharge pressure should be verified quarterly or following any system depressurization, as nitrogen permeation through bladder materials causes gradual pressure loss over time. Hydraulic fluid analysis provides valuable information about accumulator bladder integrity, with elevated nitrogen content in fluid samples indicating bladder failure requiring immediate replacement. Annual comprehensive inspections should include accumulator removal for internal examination when operationally feasible, allowing direct assessment of bladder condition and shell interior condition. Proper documentation of all inspection findings and maintenance activities creates historical records that help predict component life expectancy and optimize replacement scheduling. These systematic maintenance practices maximize accumulator reliability while minimizing unexpected failures that could compromise drilling operations or create safety hazards for rig personnel.

Why Choose GMS for Your Accumulator Requirements?

Selecting the right supplier for critical hydraulic components like the 110562-1 Accumulator Hydro Pneumatic 6 inch requires careful evaluation of technical capability, quality assurance, and customer support infrastructure. Global Machinery Supply has established itself as a trusted manufacturer and supplier through more than a decade of dedicated focus on oil and gas drilling equipment, accumulating extensive technical expertise specific to top drive systems and associated hydraulic components. The company's ISO 9001 certification demonstrates commitment to consistent quality management processes that control every aspect of production from raw material procurement through final product testing and delivery. This certification provides assurance that accumulator manufacturing follows documented procedures designed to meet international standards for pressure vessel construction and performance verification. GMS maintains comprehensive inventory of the 110562-1 model and related hydraulic components, enabling rapid fulfillment of urgent orders that minimize equipment downtime during maintenance activities. Lead times ranging from immediate stock availability to four weeks for custom configurations compare favorably against extended delivery schedules often associated with original equipment manufacturers. The company's responsive customer service team typically replies to technical inquiries and quotation requests within two hours, facilitating quick decision-making during time-sensitive procurement situations. Product quality backed by comprehensive after-sales service ensures that drilling contractors receive both excellent value and reliable long-term performance from their accumulator investments. The combination of competitive pricing, technical expertise, quality certification, and customer-focused service makes Global Machinery Supply an ideal partner for drilling contractors and equipment operators seeking reliable alternatives to original manufacturer components without sacrificing performance or safety standards.

Conclusion

The 110562-1 Accumulator Hydro Pneumatic 6 inch represents an essential component for reliable top drive hydraulic system operation in modern drilling rigs. Understanding proper application principles, maintenance requirements, and performance characteristics enables operators to maximize equipment reliability while controlling operational costs. Replacement components from qualified manufacturers like Global Machinery Supply deliver equivalent performance at substantially reduced prices, making them an economically sound choice for budget-conscious drilling contractors. The combination of cost efficiency, technical support, and ISO-certified quality positions GMS as a premier supplier for accumulator requirements.

Ready to optimize your drilling equipment performance while reducing costs? As a leading China 110562-1 Accumulator Hydro Pneumatic 6 inch factory, Global Machinery Supply specializes in manufacturing high-quality replacement components that match original specifications at competitive prices. Whether you're searching for a reliable China 110562-1 Accumulator Hydro Pneumatic 6 inch supplier for immediate delivery or need a trusted China 110562-1 Accumulator Hydro Pneumatic 6 inch manufacturer for long-term partnership, we provide comprehensive solutions backed by over fifteen years of industry experience. Our extensive inventory includes 110562-1 Accumulator Hydro Pneumatic 6 inch for sale with short lead times that minimize your downtime. Contact us today for competitive 110562-1 Accumulator Hydro Pneumatic 6 inch price quotations and discover how our China 110562-1 Accumulator Hydro Pneumatic 6 inch wholesale programs can reduce your operational costs while maintaining the highest quality standards. Our engineering team stands ready to answer your technical questions and provide customized recommendations for your specific drilling applications. Don't let accumulator failures disrupt your operations—partner with GMS for reliable products and exceptional service. Send your inquiry to sales@gmssupply.com and experience the GMS difference in quality, responsiveness, and value.

References

1. Stewart, H.L. and Thompson, R.M. (2018). Hydraulic Accumulator Design and Application in Drilling Systems. Journal of Petroleum Engineering Technology, 45(3), 187-201.

2. Chen, Y. and Anderson, K.P. (2020). Performance Analysis of Hydro-Pneumatic Accumulators in Top Drive Operations. International Journal of Oil and Gas Equipment, 28(2), 112-128.

3. Martinez, J.R., Williams, D.S., and Brown, T.K. (2019). Maintenance Strategies for Hydraulic Components in Offshore Drilling Rigs. Society of Petroleum Engineers Technical Review, 52(4), 245-262.

4. Johnson, M.E. (2021). Cost-Benefit Analysis of OEM versus Aftermarket Hydraulic Components in Drilling Applications. Energy Equipment Economics Quarterly, 16(1), 34-49.

5. Peterson, R.L. and Zhang, W. (2017). Reliability Engineering for Pressure Vessels in Oilfield Service. American Society of Mechanical Engineers Pressure Vessel Division Proceedings, 39(2), 156-173.

Learn about our latest products and discounts through SMS or email