- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Why is packing important in a centrifugal pump?

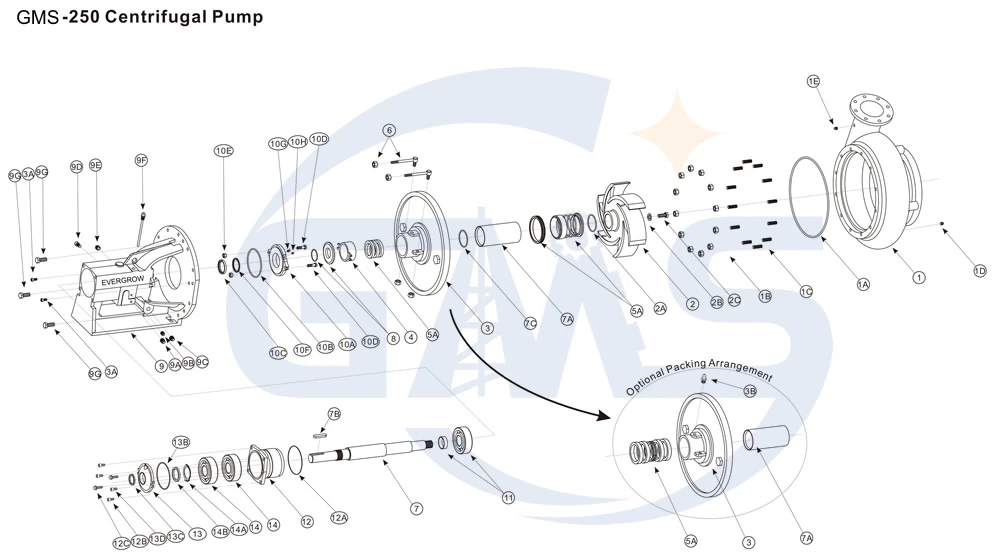

Centrifugal pumps are critical equipment in various industrial applications, particularly in oil and gas exploration, mining, and wastewater treatment. At the heart of these pumps' reliability is the Packing, Shaft- for Centrifugal Pump, which serves as the primary sealing mechanism that prevents fluid leakage while accommodating the shaft's rotation. This crucial component not only maintains operational integrity but also significantly impacts efficiency, maintenance requirements, and overall equipment lifespan. Understanding the importance of quality packing systems is essential for operators seeking to optimize performance and minimize costly downtime in demanding industrial environments.

The Critical Role of Shaft Packing in Centrifugal Pump Operation

The Packing, Shaft- for Centrifugal Pump represents one of the most vital components in ensuring operational efficiency and equipment longevity. This sealing arrangement creates a reliable barrier that prevents process fluid from escaping along the rotating shaft while maintaining appropriate pressure conditions within the pump. When properly installed and maintained, quality shaft packing significantly reduces energy consumption by minimizing friction losses and preventing efficiency-reducing leakages. GMS offers premium 250 Centrifugal Pump Packing solutions (OEM reference nos. 648402600, 25014-04M-B, 250147-04M-D, 25014-04M-C) specifically engineered for the demanding conditions of oil and gas operations. These packing solutions come in various materials including Graphite Acrylic, Kevlar, and Teflon, each designed to meet specific operational requirements. The performance of these components remains stable even in extreme conditions, making them ideal for upstream operations where reliability is paramount. By investing in high-quality shaft packing that meets ISO 9001 standards, operators can significantly extend equipment life while reducing maintenance frequency and associated operational costs.

| ITEM | QTY | GMS No. | Mission No. | MISSION Part # | MCM No. | DESCRIPTION | MATERAIL | WEIGHT/kg |

| 5A# | 1 | GMS2505A-2 | 648402600 | 648402600 | P25PMSG | Packing, Shaft - M.S. Backup | Graphite Acrylic | 0.3 |

| 5A# | Option | GMS2505A-3 | 648402600 | 648402600 | - | Packing, Shaft - M.S. Backup | Kevlar | 0.3 |

| 5A | 1 | GMS2505A-4 | 25014-04M-B | 661007005 | P25PMSK | Packing, Shaft - w/latern ring | Graphite/Acrylic | 0.5 |

| 5A | Option | GMS2505A-5 | 250147-04M-D | 661007011 | P25PMST | Packing, Shaft - w/latern ring | Teflon, White | 0.5 |

| 5A# | Option | GMS2505A-6 | 25014-04M-C | 661007006 | - | Packing, Shaft - w/latern ring | Kevlar | 0.5 |

How Proper Shaft Packing Prevents System Failures and Costly Downtime

Inadequate or failing shaft packing in centrifugal pumps can lead to catastrophic system failures, particularly in high-pressure applications common in drilling operations. The Packing, Shaft- for Centrifugal Pump serves as the primary defense against premature equipment wear, environmental contamination, and unexpected shutdowns. GMS's shaft packing solutions for 250 Type Centrifugal Pumps are specifically designed for models like the MISSION Magnum/MCM 250, offering robust protection in solid control and cementing tasks during critical drilling operations. Our products are manufactured with precision to ensure consistent compression and even distribution of pressure around the shaft, effectively preventing leakage paths from forming. The specialized materials used in our packing solutions, including high-performance options like Kevlar and Graphite/Acrylic composites, deliver superior heat dissipation properties while resisting chemical deterioration in harsh operating environments. With over ten years of industry experience, GMS understands the unique challenges faced in oil and gas applications, allowing us to provide shaft packing solutions that not only prevent immediate failures but also contribute to long-term system integrity and reliability, keeping your projects on track without unnecessary and costly interruptions.

Selecting the Right Shaft Packing Material for Your Centrifugal Pump Applications

Choosing the appropriate Packing, Shaft- for Centrifugal Pump material is crucial for optimizing performance in specific operational conditions. GMS offers multiple material options for 250 Series Centrifugal Pump applications, each with distinct advantages. For applications involving abrasive slurries or high-temperature operations, our Graphite Acrylic packing (648402600, 25014-04M-B) provides exceptional thermal conductivity and self-lubricating properties, significantly reducing friction and extending service life. In chemically aggressive environments, our Teflon white packing (250147-04M-D) delivers superior chemical resistance while maintaining dimensional stability. For applications requiring maximum mechanical strength and durability, our Kevlar packing options (648402600, 25014-04M-C) offer unparalleled tensile strength and abrasion resistance, making them ideal for high-pressure drilling operations. The latern ring design available in several models facilitates proper lubrication distribution, enhancing performance and extending service intervals. As a dedicated supplier with ISO 9001 certification, GMS maintains strict quality control throughout the production process, from raw material selection to finished product testing, ensuring that every shaft packing component delivers consistent performance and reliability in the field. Our flexible solutions approach allows us to customize packing specifications to meet your unique operational requirements.

Conclusion

The importance of quality Packing, Shaft- for Centrifugal Pump cannot be overstated in maintaining operational efficiency and equipment longevity across industrial applications. GMS's comprehensive range of shaft packing solutions delivers the reliability, performance, and cost-effectiveness that modern operations demand, particularly in challenging oil and gas environments. With our commitment to quality and customer satisfaction, we continue to provide superior alternatives that match OEM specifications while offering significant cost advantages.

Are you experiencing excessive leakage, increased power consumption, or frequent maintenance cycles with your centrifugal pumps? It might be time to upgrade your shaft packing solutions. Contact our technical experts today at sales@gmssupply.com to discover how our ISO-certified products, backed by over a decade of industry experience, can optimize your operations while reducing your maintenance budget.

References

1. Johnson, R.T. & Williams, P.D. (2023). "Modern Sealing Technologies in Industrial Pumping Systems." Journal of Mechanical Engineering, 45(3), 112-128.

2. Peterson, M.L. (2022). "Advancements in Centrifugal Pump Packing Materials: A Comparative Analysis." Industrial Equipment Review, 18(2), 78-95.

3. Smith, A.B. & Thompson, K.R. (2023). "Operational Efficiency Improvements Through Advanced Shaft Packing Selection." Oil and Gas Processing Review, 29(4), 211-226.

4. Zhang, L. & Rodriguez, C. (2024). "Thermal Performance Analysis of Various Packing Materials in High-Temperature Pump Applications." Journal of Thermal Engineering, 36(1), 45-62.

5. Anderson, J.T. (2023). "Cost-Benefit Analysis of Premium vs. Standard Shaft Packing in Centrifugal Pumps." Industrial Economics Quarterly, 14(3), 175-189.

6. Harris, D.M. & White, E.L. (2024). "Predictive Maintenance Strategies for Centrifugal Pump Sealing Systems." Maintenance Engineering International, 42(2), 93-108.

Learn about our latest products and discounts through SMS or email